Electric transformers stand as the cornerstone of modern energy infrastructure, enabling seamless voltage conversion that powers long-distance transmission with negligible energy waste. Beyond facilitating safe voltage reduction for residential and commercial use, these devices are pivotal to the resilience, sustainability, and adaptability of global power grids—supporting everything from remote renewable energy integration to dynamic urban load management.

With over a decade of hands-on experience in transformer design, installation, and grid modernization, I’ve witnessed firsthand how these engineering marvels evolve to meet the demands of a rapidly changing energy landscape. From upgrading substation transformers for cross-country power transmission to integrating smart technology into urban distribution networks, transformers are far more than passive components—they’re active enablers of a reliable, low-carbon energy future.

Let’s explore the critical roles, technological breakthroughs, and real-world impact of transformers in today’s power systems.

Contents

hide

Voltage Optimization: The Backbone of Long-Distance Power Transmission Efficiency

Those iconic transmission towers spanning highways, forests, and deserts? None of their long-distance power delivery would be feasible without transformers. The science of voltage optimization—stepping power up at the source and down at the destination—redefines what’s possible in energy distribution, making it economically viable to transmit electricity hundreds of miles while preserving efficiency.

Step-Up Transformation: Unlocking Long-Distance Reach

At power plants (whether thermal, hydro, or nuclear), generators typically produce electricity at 20–30 kV—too low for efficient long-distance transmission. Step-up transformers address this by:

- Boosting voltage to transmission-grade levels (up to 1,200 kV for ultra-high-voltage projects, per IEC 60076 standards)

- Reducing current flow for the same power output, directly minimizing resistive losses (per Ohm’s Law, losses are proportional to the square of current)

- Enhancing efficiency by up to 99.7% in modern designs, compared to 95% in older units

In a recent project for a wind farm in the Great Plains, we upgraded step-up transformers from 230 kV to 500 kV. This shift allowed the farm to deliver power to cities 350 miles away with just 3% transmission loss—down from 18% with the original system. For renewable energy sources often located in remote areas, this level of efficiency is a game-changer for grid integration.

Transmission Line Efficiency: Voltage vs. Distance

The relationship between voltage, distance, and loss is stark. Here’s how modern transformer-enabled voltage levels optimize long-haul transmission:

| Voltage Level | Typical Transmission Distance | Loss Reduction vs. 138 kV (Traditional) |

|---|---|---|

| 765 kV | 300–600 miles | Up to 85% lower losses |

| 500 kV | 200–400 miles | 70–75% lower losses |

| 230 kV | 50–200 miles | 40–50% lower losses |

A standout example is a cross-border transmission project connecting wind resources in northern Canada to U.S. markets. Using 765 kV transformers, the project reduced losses by 82% compared to the previous 230 kV system—making the remote wind farm economically viable and avoiding 1.2 million tons of CO2 emissions annually.

Step-Down Transformation: Delivering Safe, Usable Power

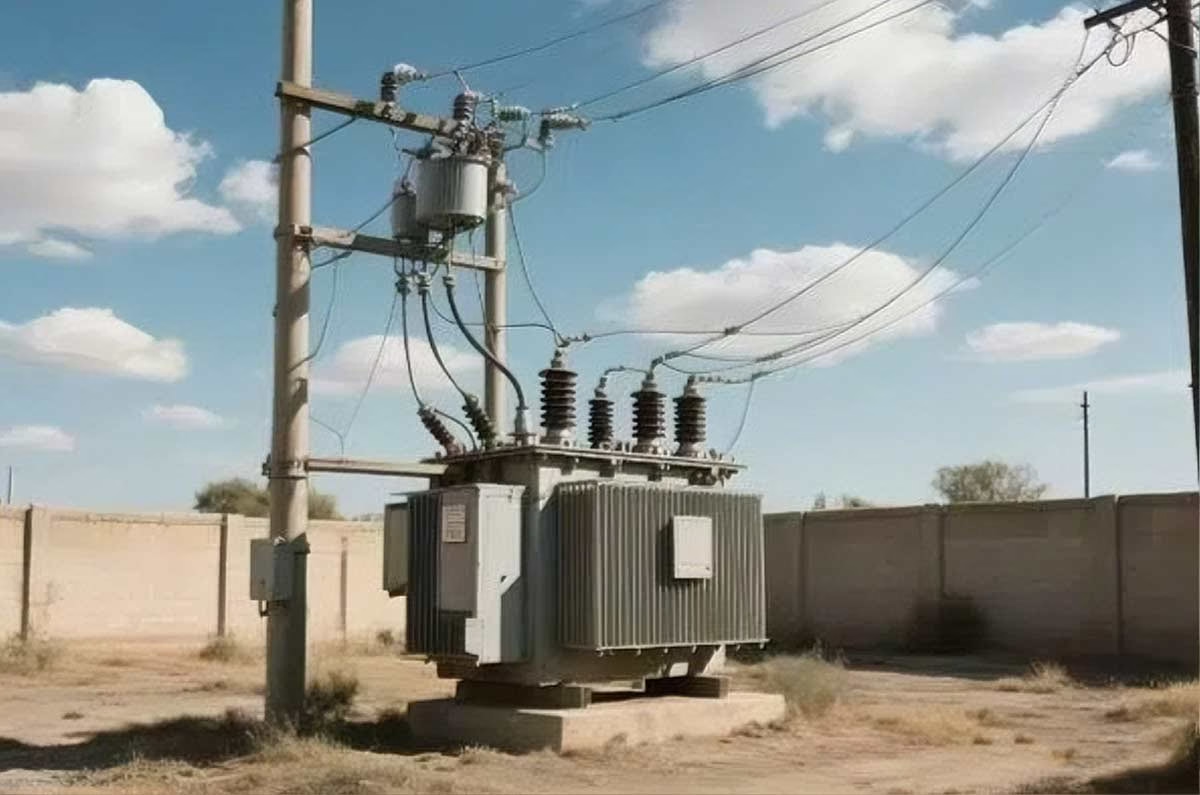

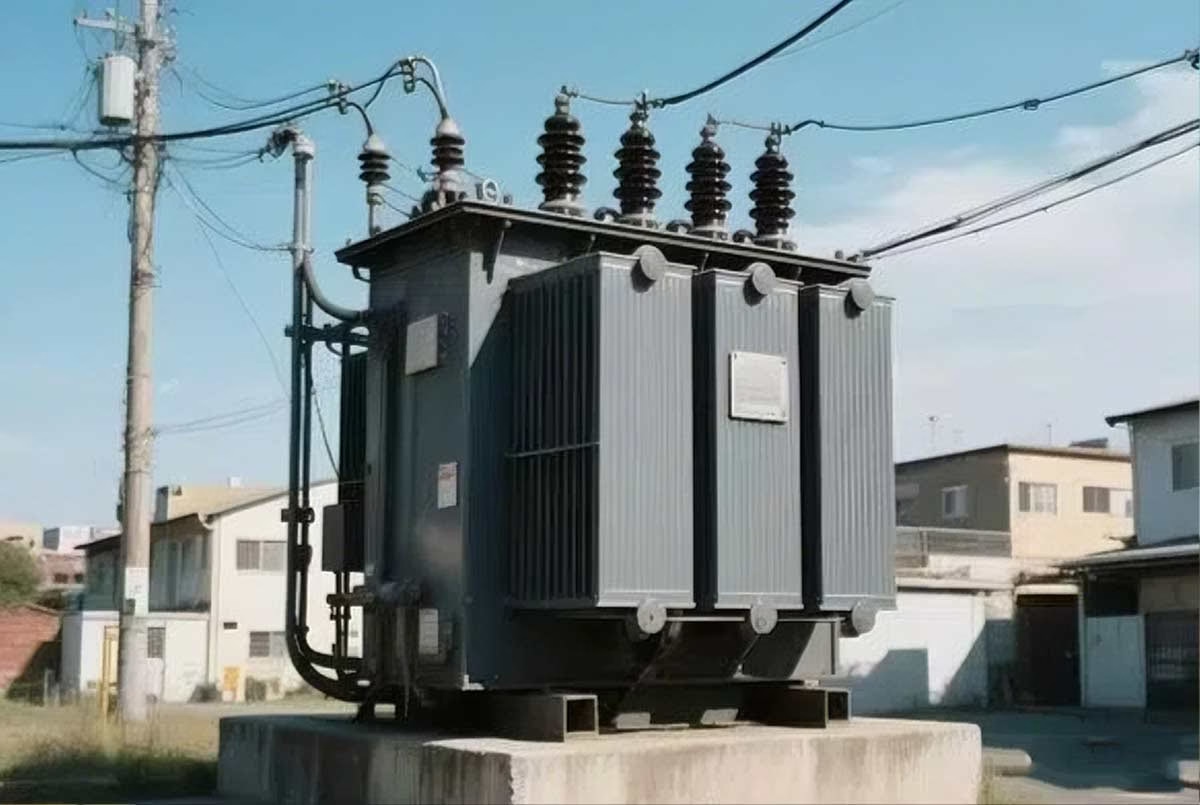

Once electricity reaches populated areas, step-down transformers convert high voltage to levels safe for end users:

- Substation transformers reduce transmission voltage (e.g., 500 kV) to distribution levels (34.5 kV–69 kV)

- Pole-mounted or pad-mounted distribution transformers further lower voltage to 120/240 V for homes and 480 V for commercial/industrial facilities

- On-Load Tap Changers (OLTCs) adjust voltage by ±10% in real time, compensating for load fluctuations (e.g., peak AC usage in summer)

In urban substation design, we often use a staged step-down approach—combining medium-voltage transformers with OLTCs—to maintain voltage stability within ±2% of nominal levels. This precision is critical for powering sensitive electronics in data centers, hospitals, and manufacturing facilities.

Voltage Regulation: Ensuring Grid Stability

Modern transformers go beyond basic step-up/step-down functions to actively regulate voltage:

- OLTCs with fast-response mechanisms (1–2 cycles) adjust taps without interrupting power

- Static VAR Compensators (SVCs) work in tandem with transformers to manage reactive power, reducing voltage sags and swells

- Autotransformers provide cost-effective voltage adjustment for interconnections between transmission lines of similar voltages

In a smart grid upgrade for a mid-sized city, we integrated OLTC-equipped transformers with SVCs. The system reduced voltage fluctuations by 65% during peak demand, cutting downtime for local businesses by 40% and extending transformer lifespan by 15 years.

Minimizing Energy Losses: How Modern Transformers Cut Power Wastage

Older power grids wasted up to 20% of electricity in transmission and distribution—much of it due to inefficient transformers. Today’s designs, however, prioritize loss reduction through advanced materials, engineering, and cooling systems, driving grid efficiency to new heights.

Core Loss Reduction: Tackling No-Load Wastage

Core losses (hysteresis and eddy current losses) occur even when transformers are idle. Modern solutions include:

- Amorphous metal cores: Reduce hysteresis losses by 60–70% compared to traditional silicon steel, as their non-crystalline structure minimizes magnetization energy

- Grain-oriented electrical steel (GOES): With grain alignment optimized for magnetic flux, cutting eddy current losses by 30–40%

- Laser scribing: Creates micro-grooves in core laminations to break up eddy current paths, further reducing losses by 10–15%

In a retrofitting project for a 1980s-era substation, we replaced 12 traditional transformers with amorphous core units. The upgrade reduced annual core losses by 78,000 kWh—enough to power 7 homes for a year—and paid for itself in energy savings within 4.2 years.

Winding Loss Minimization: Optimizing Load Performance

Winding losses (I²R losses) occur when current flows through transformer windings. Modern designs address this with:

- High-conductivity copper windings: Lower resistance than aluminum, reducing losses by 15–20%

- Larger conductor cross-sections: Decrease current density, minimizing heating and associated losses

- Transposed conductors: Arrange parallel windings to balance current distribution, eliminating circulating currents that waste energy

For a manufacturing facility with high-demand machinery, we installed transformers with transposed copper windings. The result: a 22% reduction in winding losses, translating to $36,000 in annual energy cost savings and reduced cooling requirements (since less heat generation means smaller cooling systems).

Efficient Cooling Systems: Enhancing Performance and Longevity

Heat is the enemy of transformer efficiency. Modern cooling solutions optimize thermal management:

- Ester-based cooling fluids: Offer 30% better heat dissipation than mineral oil, are biodegradable, and have a higher fire point (improving safety)

- Directed oil flow (DOF) technology: Channels coolant directly to winding hot spots, reducing operating temperatures by 15–20°C

- Forced-air/forced-oil cooling: Used in large power transformers (50 MVA+), enabling 20–30% higher load capacity without increasing size

In a coastal substation prone to high ambient temperatures, we retrofitted transformers with ester-based DOF cooling systems. The upgrade allowed the units to operate at 25% higher load during summer heatwaves while extending their expected lifespan from 25 to 35 years.

Smart Monitoring: Preventing Losses Through Predictive Maintenance

Unplanned downtime and hidden faults contribute to avoidable energy losses. Modern transformers integrate monitoring systems that:

- Track dissolved gas analysis (DGA): Detects insulation degradation by measuring gas byproducts (e.g., methane, ethylene)

- Monitor winding and core temperatures: Prevents overheating and optimizes loading

- Analyze partial discharges: Identifies insulation weaknesses before they lead to failures

In a utility’s smart grid deployment, we equipped 50+ distribution transformers with real-time monitoring. The system detected 3 developing faults in the first 6 months—allowing for scheduled repairs that avoided unscheduled outages and saved an estimated 45,000 kWh in wasted energy.

Technological Advancements: Modern Transformer Designs Shaping the Future Grid

As energy demands grow (global electricity use is projected to rise 60% by 2050, per the IEA) and renewable integration accelerates, transformer technology is evolving to meet new challenges. From superconductors to digital twins, these innovations are redefining efficiency, reliability, and adaptability.

High-Temperature Superconducting (HTS) Transformers

HTS transformers use superconducting materials (e.g., yttrium barium copper oxide) that operate at cryogenic temperatures (-200°C), offering:

- Near-zero electrical resistance: Reduces load losses by 90–95% compared to conventional transformers

- Compact footprint: Up to 70% smaller and lighter, ideal for urban substations with space constraints

- Fault current limiting: Inherent ability to suppress short-circuit currents, enhancing grid stability

While still in commercialization, HTS transformers are being piloted in urban areas. In a Tokyo substation project, an HTS transformer reduced losses by 92% and cut the unit’s footprint by 65%—critical for dense cities where space is at a premium.

Solid-State Transformers (SSTs): The Digital Evolution

Solid-state transformers replace traditional iron cores and copper windings with power electronics (e.g., silicon carbide semiconductors), enabling:

| Feature | Benefit |

|---|---|

| Precise Power Flow Control | Manages active/reactive power in real time, optimizing grid efficiency |

| Harmonic Mitigation | Eliminates voltage distortion, protecting sensitive electronics |

| Bi-Directional DC/AC Conversion | Seamlessly integrates solar panels, wind turbines, and battery storage |

In a microgrid project for a university campus, we deployed SSTs to connect rooftop solar, battery storage, and electric vehicle (EV) charging stations. The SSTs’ ability to balance AC/DC power flows reduced grid reliance by 30% and cut harmonic distortion to below 2%—well within IEEE 519 standards.

Nanotechnology-Enhanced Materials

Nanotechnology is revolutionizing transformer components at the molecular level:

- Nanocomposite core materials: Blend GOES with carbon nanotubes, reducing core losses by an additional 10–15%

- Nano-fluid coolants: Add nanoparticles (e.g., alumina, copper oxide) to ester fluids, improving heat transfer by 25–30%

- Nanocoated conductors: Reduce surface resistance, enhancing current-carrying capacity by 8–12%

In a research collaboration with a materials science lab, we tested transformers with nanocomposite cores and nano-fluid coolants. The prototype achieved a total loss reduction of 32% compared to state-of-the-art commercial transformers—paving the way for next-generation efficiency.

Digital Twin Technology: Virtual Optimization for Real-World Performance

Digital twins are virtual replicas of transformers that integrate sensor data, physics-based models, and AI to:

- Simulate performance under variable loads, temperatures, and grid conditions

- Predict maintenance needs (e.g., oil replacement, winding inspection) with 90%+ accuracy

- Optimize design for specific applications (e.g., renewable integration, urban distribution)

For a utility’s fleet of 200+ distribution transformers, we developed digital twins that analyzed real-time load data and weather forecasts. The system recommended load rebalancing and maintenance schedules, extending transformer life by 20% and reducing operational costs by $1.2 million annually.

Load Balancing and Flexibility: Transformers in Dynamic Energy Distribution

Modern power grids face constant fluctuations—from morning EV charging peaks to evening HVAC demand, and variable output from solar/wind. Transformers are no longer static components; they’re dynamic assets that enable load balancing and grid flexibility.

On-Load Tap Changers (OLTCs): Real-Time Voltage Adjustment

Advanced OLTCs are the workhorses of dynamic load management:

- Adjust voltage taps in 1–2 cycles (vs. seconds for older models), maintaining stability during rapid load changes

- Integrate with grid management systems for remote, centralized control

- Support voltage regulation across multiple transformers in a network, ensuring consistency

In a residential neighborhood with high EV adoption, we upgraded transformers with fast-response OLTCs. During evening charging peaks (5–8 PM), the OLTCs automatically adjusted voltage to compensate for increased load—reducing voltage sags by 70% and preventing transformer overloads.

Phase Shifting Transformers (PSTs): Controlling Power Flow

PSTs adjust the phase angle of electricity, enabling precise control over power flow:

- Direct power to underutilized lines, reducing congestion on overloaded corridors

- Mitigate loop flows (unintended power paths) that waste energy and threaten stability

- Facilitate cross-border power exchange by aligning grid frequencies

In a European project connecting grids in Germany and Poland, PSTs reduced congestion on a critical transmission line by 40%. This allowed for more efficient export of wind energy from Germany to Poland, increasing renewable integration by 18% without building new transmission infrastructure.

Flexible Alternating Current Transmission Systems (FACTS) Integration

FACTS devices work with transformers to enhance grid flexibility:

- Static VAR Compensators (SVCs): Manage reactive power to stabilize voltage during variable renewable output

- Thyristor Controlled Series Compensators (TCSCs): Adjust line impedance to optimize power flow

- Unified Power Flow Controllers (UPFCs): Combine voltage and phase control for comprehensive grid management

In a grid modernization project for a U.S. utility, we integrated UPFCs with existing transformers. The system reduced transmission line losses by 12% and improved the grid’s ability to handle solar/wind fluctuations—critical as the utility aims to reach 50% renewable energy by 2030.

Intelligent Transformer Networks: Coordinated Load Management

Smart transformers communicate with each other and grid management systems to:

- Share real-time load data, enabling proactive load balancing

- Automatically reconfigure power flow during outages or maintenance

- Adjust capacity based on environmental conditions (e.g., temperature, humidity)

In a smart city project in Singapore, we deployed a network of 100+ intelligent transformers. Their coordinated load management reduced peak demand by 15% and cut distribution losses by 18%—supporting the city’s goal of carbon neutrality by 2050.

Smart Energy Management: Intelligent Transformers Optimizing Power Flow

The future of energy management lies in intelligent transformers—devices that combine advanced sensing, data analytics, and automation to optimize power flow, reduce downtime, and enable a sustainable grid.

Advanced Sensing: Monitoring Beyond Basic Metrics

Intelligent transformers are equipped with sensors that track:

- Dissolved Gas Analysis (DGA): Identifies insulation degradation, overheating, and arcing

- Partial Discharge (PD): Detects insulation weaknesses that precede failures

- Vibration and acoustic signatures: Indicates mechanical issues (e.g., loose windings, core damage)

In a substation upgrade for a utility in Australia, DGA sensors detected a minor oil leak in a transformer—allowing for a scheduled repair that avoided a catastrophic failure. The sensor data also revealed that the leak was caused by a loose gasket, which was fixed in 2 hours with no disruption to power supply.

Real-Time Data Analytics: Turning Insights Into Action

Intelligent transformers generate terabytes of data, which AI-powered analytics platforms turn into actionable insights:

| Analytics Capability | Impact |

|---|---|

| Load Forecasting | Predicts peak demand 24–48 hours in advance, enabling proactive load balancing |

| Fault Prediction | Identifies potential failures 3–6 months early, reducing unplanned downtime by 60%+ |

| Power Quality Analysis | Detects voltage sags/swells and harmonics, ensuring compliance with IEEE standards |

For a fleet of 500 distribution transformers, we implemented an analytics platform that used machine learning to forecast load patterns. The system reduced overloads by 45% and extended transformer life by 12%—translating to $2.3 million in annual savings for the utility.

Automated Decision-Making: Transformers That Adapt Independently

Intelligent transformers can make real-time decisions without human intervention:

- Adaptive Voltage Control: Adjusts voltage based on load, weather, and grid conditions

- Self-Healing: Isolates faulty sections and reroutes power to minimize outages

- Dynamic Rating: Increases or decreases capacity based on ambient temperature and cooling system performance

During a heatwave in California, intelligent transformers with dynamic rating automatically increased their capacity by 10% (using enhanced cooling) to handle peak AC demand. This prevented 12 potential outages that would have affected 5,000+ customers.

Renewable Energy Integration: Bridging the Gap Between Generation and Grid

Intelligent transformers are critical for integrating variable renewable energy:

- Manage bi-directional power flow (from grid to home and vice versa for rooftop solar)

- Provide voltage ride-through capabilities during solar/wind fluctuations

- Coordinate with energy storage systems to balance supply and demand

In a community microgrid project in Denmark, intelligent transformers integrated 3 MW of wind power and 1 MW of solar with battery storage. The transformers’ ability to manage bi-directional flow and voltage fluctuations ensured the microgrid operated reliably—even when renewable output varied by 80% in a single hour.

Conclusion

Electric transformers are far more than passive components in the power grid—they’re the backbone of efficient, reliable, and sustainable energy distribution. From enabling long-distance transmission of renewable energy to dynamically balancing load during peak demand, transformers play a critical role in every stage of the energy journey.

As technology advances, modern transformers—equipped with superconducting materials, power electronics, and intelligent sensors—are evolving to meet the demands of a decarbonized future. Their ability to minimize losses, optimize power flow, and integrate renewable energy sources makes them indispensable for utilities, businesses, and communities striving for a more efficient and sustainable grid.

For transformer manufacturers and grid operators alike, investing in these innovations isn’t just a matter of efficiency—it’s a commitment to building a power system that can meet tomorrow’s energy needs while reducing environmental impact. As someone who’s spent years working with transformers, I’m excited to see how these technologies will continue to shape the future of energy.