Electrical transformers are precision-engineered devices that adjust voltage levels in electrical circuits, enabling the safe, efficient flow of electricity across our homes, businesses, and industrial facilities. At their core, they leverage electromagnetic induction to transfer energy between isolated circuits—no moving parts, no direct electrical contact, just the power of magnetic fields. This technology isn’t just a technical marvel; it’s the foundation of our interconnected power grid, making long-distance energy transmission feasible and everyday electrical use safe.

With decades of expertise in power system design and transformer technology, we’ve witnessed how these devices shape modern life—from powering a smartphone charger to integrating gigawatts of renewable energy. Below, we demystify their functionality, science, and real-world impact, offering a clear, practical guide to understanding transformers.

Contents

hide

The Core Function of Electrical Transformers: Voltage Manipulation

Imagine plugging your laptop directly into a 400,000-volt transmission line—disaster would strike instantly. Transformers solve this critical problem by manipulating voltage levels, acting as the “middlemen” that bridge high-voltage power generation and low-voltage end use. Their ability to step voltage up or down is the single most important function in electrical systems, enabling efficiency, safety, and compatibility.

Why Voltage Manipulation Is Non-Negotiable

- Efficient Long-Distance Transmission: Power plants generate electricity at 10–30kV, but transmitting this low voltage over hundreds of miles would result in 50%+ energy loss (due to P=I2R losses). Transformers step voltage up to 69kV–765kV, reducing current and cutting losses to less than 5%.

- Safe End-Use: Most household and commercial devices require 120V–480V to operate safely. Transformers step down high-voltage grid power to these levels, eliminating electrical hazards.

- Device Compatibility: From a 5V smartphone charger to a 4160V industrial motor, every electrical device has unique voltage needs. Transformers tailor power to these requirements, ensuring optimal performance and longevity.

How Transformers Manipulate Voltage

The magic of voltage adjustment lies in three key components and the principle of electromagnetic induction:

- Primary Coil: Connected to the input power source (e.g., 138kV grid power), this coil carries alternating current (AC), which creates a dynamic magnetic field.

- Iron Core: A laminated silicon steel core concentrates and directs the magnetic field, ensuring efficient energy transfer between coils.

- Secondary Coil: Wrapped around the same core, this coil picks up the changing magnetic field, inducing a voltage proportional to the number of its turns relative to the primary coil.

The “turns ratio” (secondary turns ÷ primary turns) dictates voltage change:

- A 1:10 turns ratio (10x more turns in the secondary) steps 12kV up to 120kV.

- A 10:1 ratio steps 12kV down to 1.2kV.

Real-World Voltage Manipulation Scenarios

| Application | Transformer Type | Input Voltage | Output Voltage | Purpose |

|---|---|---|---|---|

| Power Plant | Step-Up | 25kV | 500kV | Long-distance transmission |

| Substation | Step-Down | 500kV | 12kV | Regional distribution |

| Residential Neighborhood | Pad-Mounted | 12kV | 240V/120V | Home use (HVAC, appliances) |

| Electric Vehicle Charger | Isolation/Step-Down | 240V | 400V DC | Safe EV battery charging |

How Transformers Convert Power: From High to Low Voltage

Transformers don’t just change voltage—they convert power between levels while preserving energy (minus minimal losses). This conversion is based on the fundamental law of energy conservation: power in equals power out ( Vp×Ip=Vs×Is ), meaning voltage and current change in inverse proportion.

The Power Conversion Process

Let’s walk through a real-world example of power flow from a wind farm to a home:

- Wind Turbine Output: 10MW of power at 690V (high current, low voltage).

- Step-Up Transformer: Increases voltage to 34.5kV, reducing current from ~14,500A to ~290A—cutting transmission losses by 99%.

- Grid Transmission: 34.5kV power travels 50 miles to a local substation.

- Substation Step-Down: Reduces voltage to 12kV for neighborhood distribution.

- Pole-Mounted Transformer: Further steps down to 240V, increasing current to ~41,600A (split across multiple homes) for safe use.

Throughout this process, the total power remains ~10MW (minus 2–3% total losses), but voltage and current adjust to meet the needs of each stage.

Step-Up vs. Step-Down Conversion: Key Differences

| Type | Voltage Change | Current Change | Core Application | Efficiency |

|---|---|---|---|---|

| Step-Up | Increases (e.g., 25kV → 500kV) | Decreases | Power plant to grid | 99.5%+ (large units) |

| Step-Down | Decreases (e.g., 12kV → 240V) | Increases | Grid to end-users | 98–99% (distribution units) |

Minimizing Conversion Losses

Modern transformers are remarkably efficient, but two types of losses are unavoidable:

- Core Losses (Iron Losses): Energy wasted re-magnetizing the iron core (~2–5% of total power). Mitigated by using grain-oriented silicon steel and laminated cores.

- Copper Losses (Winding Losses): Heat generated by current flowing through copper windings (~1–3% of total power). Reduced by using thicker copper wires and optimizing coil design.

For large power transformers (100MVA+), these losses are so minimal that they can operate at 99.7%+ efficiency—making them one of the most efficient machines ever built.

The Science Behind Transformers: Electromagnetic Induction

Transformers owe their functionality to electromagnetic induction, a principle discovered by Michael Faraday in 1831. This phenomenon describes how a changing magnetic field induces an electric current in a conductor—and it’s the invisible force that powers every transformer on the planet.

How Electromagnetic Induction Works in Transformers

The process unfolds in four simple steps:

- AC Power Input: Alternating current flows through the primary coil, reversing direction 50–60 times per second (depending on the grid frequency).

- Dynamic Magnetic Field: The alternating current creates a magnetic field that expands and collapses with the current’s rhythm—think of it as a magnetic “wave” rippling through the core.

- Flux Linkage: The iron core concentrates this magnetic flux (lines of magnetic force), ensuring it links with the secondary coil. Without the core, only 1–10% of the flux would reach the secondary, making the transformer inefficient.

- Induced Voltage: As the magnetic flux changes, it cuts through the secondary coil’s wires, inducing an electromotive force (EMF) and generating an alternating current. Faraday’s Law quantifies this: EMF=−NdtdΦ, where N is the number of coil turns and dtdΦ is the rate of flux change.

The Transformer Equation: Quantifying Voltage Change

The relationship between primary and secondary voltage is defined by the turns ratio:VpVs=NpNs

- Vs = Secondary voltage

- Vp = Primary voltage

- Ns = Number of secondary turns

- Np = Number of primary turns

For example: A transformer with 1,000 primary turns and 10,000 secondary turns (Ns/Np=10) will step 12kV up to 120kV.

Key Design Innovations for Induction Efficiency

- Laminated Core: The core is stacked from thin (0.25–0.35mm) insulated steel sheets, blocking eddy currents (circulating currents that generate heat) and reducing core losses by 90%.

- Concentric Coil Winding: Primary and secondary coils are wrapped concentrically around the core, maximizing flux linkage and minimizing leakage flux (flux that doesn’t link both coils).

- Insulation Materials: High-grade epoxy resin or Nomex insulation separates coil turns, withstanding voltage spikes (e.g., lightning strikes) and preventing short circuits.

Transformers in Daily Life: From Smartphones to Power Grids

Transformers are everywhere—often hidden in plain sight—powering nearly every electrical device we use. Their versatility spans from tiny components in consumer electronics to massive units at power plants, proving that size doesn’t limit their impact.

Small-Scale Transformers: Consumer Electronics

- Smartphone Chargers: The “brick” in your charger contains a miniature transformer that steps 120V/240V AC down to 5V/9V DC, safely charging your phone without overheating.

- Laptop Power Supplies: These use isolated transformers to convert grid power to low-voltage DC (19V typical), protecting the laptop’s sensitive circuitry from voltage fluctuations.

- Doorbells: A small 16V transformer reduces household 120V to a safe voltage for doorbell chimes—preventing electric shocks if the wiring is exposed.

Medium-Scale Transformers: Homes & Businesses

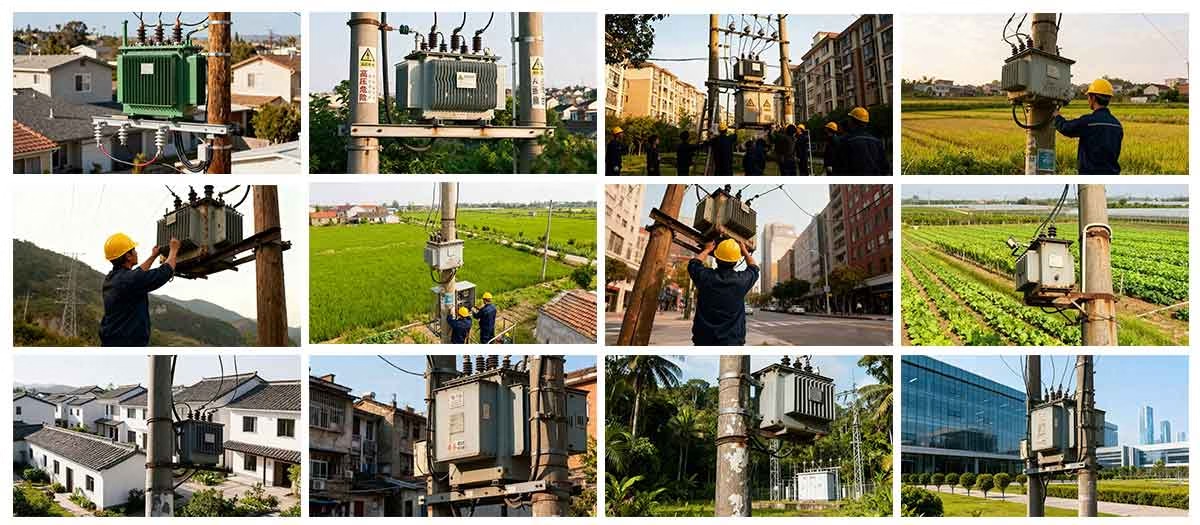

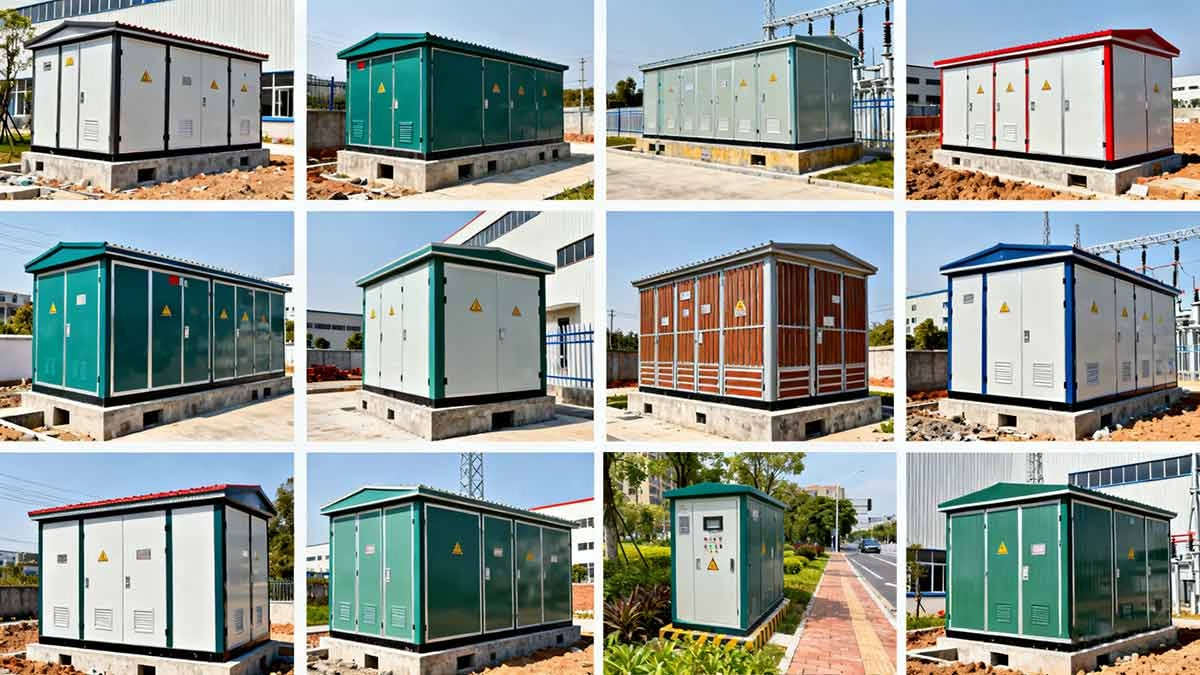

- Residential Distribution: Pad-mounted or pole-mounted transformers (10–50kVA) power neighborhoods, stepping 12kV down to 240V for HVAC systems, EV chargers, and kitchen appliances. A modern home with a heat pump and EV charger typically requires a 30–40kVA transformer (up from 20kVA a decade ago).

- Commercial Buildings: Dry-type transformers (75–2,500kVA) supply 480V for office HVAC and 208V for lighting/IT equipment. Hospitals use isolation transformers to protect MRI machines and patient monitors from electrical noise.

- Outdoor Lighting: Low-voltage landscape lighting systems use 12V/24V transformers, enhancing safety in wet environments (e.g., gardens, pools).

Large-Scale Transformers: Power Grids & Industry

- Power Plants: Step-up transformers (100MVA+) boost generator output from 25kV to 500kV, enabling cross-country transmission.

- Substations: Step-down transformers (50–500MVA) reduce high-voltage grid power to 12kV–34.5kV for regional distribution.

- Industrial Facilities: Custom transformers (1–100MVA) power heavy machinery—e.g., 4160V transformers for factory motors, or low-voltage (8V) transformers for aluminum smelting electrolysis.

The Role of Transformers in Modern Energy Systems: Efficiency & Sustainability

As the world shifts to renewable energy and smart grids, transformers are evolving from passive voltage converters to active, intelligent components that drive efficiency and sustainability. They’re the critical link between variable renewable sources (solar, wind) and the grid, ensuring stable power delivery while reducing carbon emissions.

Integrating Renewable Energy

Renewable energy presents unique challenges—variable output, distributed generation, and bidirectional power flow—that transformers are engineered to solve:

- Variable Output Management: Wind and solar power fluctuate with weather conditions. Smart transformers adjust voltage in real time to handle these changes, preventing grid instability.

- Distributed Generation Connection: Rooftop solar panels generate 240V AC, but transformers step this up to 12kV for grid feed-in, or down to 48V for home battery storage.

- Bidirectional Power Flow: Modern transformers support two-way energy flow, allowing excess solar power to feed back into the grid and earn homeowners credits.

Smart Transformers for Smart Grids

Smart transformers (also called “intelligent transformers”) are revolutionizing grid management with built-in IoT technology:

- Real-Time Monitoring: Sensors track temperature, load, and voltage, sending data to grid operators for predictive maintenance. This reduces downtime by 30% and extends transformer life by 15–20 years.

- Voltage Regulation: On-Load Tap Changers (OLTCs) adjust voltage dynamically, compensating for peak demand (e.g., evening EV charging) without manual intervention.

- Fault Isolation: Smart transformers detect short circuits or voltage spikes and isolate affected areas, preventing widespread outages.

Sustainability Through Efficiency

Transformers are key to reducing energy waste in power systems:

- Low-Loss Designs: Modern transformers use amorphous steel cores (vs. traditional silicon steel), cutting core losses by 50% and saving millions of kWh annually.

- Eco-Friendly Coolants: Replacing mineral oil with biodegradable esters or natural esters eliminates the risk of environmental contamination from leaks.

- EV Charging Support: Transformers power fast-charging stations, stepping up grid power to 400V DC for 15–350kW charging speeds. They also balance EV load with other grid demands, avoiding overloads.

Future Trends: The Next Generation of Transformers

- Solid-State Transformers (SSTs): Replace iron cores and copper windings with power electronics, offering faster switching, smaller size, and compatibility with DC grids (critical for EVs and energy storage).

- High-Temperature Superconducting (HTS) Transformers: Use superconducting materials to eliminate copper losses, achieving 99.9% efficiency and reducing size by 70%.

- Nanomaterial Cores: Advanced nanocrystalline materials enhance magnetic flux density, further reducing core losses and improving efficiency.

Conclusion

Electrical transformers are the unsung heroes of our modern world—quietly converting, distributing, and protecting power across every corner of our lives. From the tiny transformer in your phone charger to the massive units powering renewable energy farms, they enable efficiency, safety, and sustainability in ways no other device can.

As we transition to a cleaner, smarter energy future, transformers will continue to evolve—becoming more efficient, connected, and adaptable. They’re not just components of the grid; they’re the foundation of a decarbonized, electrified world. Whether you’re a homeowner, business owner, or energy professional, understanding transformers helps you appreciate the engineering marvel that keeps our lights on, our devices charged, and our planet moving toward a more sustainable future.