With over a decade in the transformer manufacturing and engineering space, I’ve witnessed firsthand how these unsung workhorses underpin every aspect of modern electrical infrastructure. From the massive power transformers at utility substations to the compact pole-mounted units powering residential neighborhoods, transformers quietly ensure electricity flows efficiently, safely, and reliably—keeping our homes lit, businesses running, and critical systems operational. Beyond simple voltage adjustment, they’re the guardians of grid stability, protectors of sensitive equipment, and enablers of renewable energy integration. Let’s unpack the science, applications, and innovations that make transformers indispensable to our electrical world.

Contents

hide

How Transformers Convert Voltage: The Science Behind Step-Up and Step-Down Functionality

Ever plugged in a device during an international trip only to see it short-circuit? That’s the consequences of voltage mismatch—and transformers are the solution that prevents this scenario for billions of users daily. But what exactly happens inside these devices to adjust voltage, and how do they make long-distance power transmission feasible?

At their core, transformers operate on the principle of electromagnetic induction—a phenomenon first quantified by Michael Faraday in the 19th century. Each transformer features two coils (primary and secondary) wrapped around a magnetic core (typically made of silicon steel or amorphous metal for efficiency). When alternating current (AC) passes through the primary coil, it generates a constantly changing magnetic field. This field induces a voltage in the secondary coil, with the voltage output determined by the ratio of turns between the two coils.

From my early days troubleshooting small distribution transformers to leading large-scale substation upgrades, I’ve learned that the efficiency of voltage conversion hinges on three critical factors: coil design, core material, and magnetic field optimization. Let’s break down the process with real-world context:

The Fundamentals of Electromagnetic Induction

Transformers rely on three key principles to function:

- Faraday’s Law: A changing magnetic field induces an electromotive force (voltage) in a conductor.

- Alternating Current (AC): Unlike direct current (DC), AC reverses direction periodically, creating the dynamic magnetic field needed for induction.

- Mutual Induction: The magnetic field from the primary coil transfers energy to the secondary coil without physical contact—enabling isolated voltage conversion.

I still recall my first hands-on experiment with a small 1kVA demonstration transformer. By adjusting the number of turns on the secondary coil from 100 to 200, we doubled the output voltage—proving how this simple ratio dictates performance. That lesson stuck with me: even the most advanced transformers boil down to this basic relationship between coil turns and voltage.

Step-Up Transformers: Powering Long-Distance Transmission

When electricity is generated at power plants (typically 11 kV to 33 kV), it’s too low for efficient long-distance transmission. High current at low voltage causes significant energy loss as heat in transmission lines (thanks to Ohm’s Law, where power loss = I²R). Step-up transformers solve this by increasing voltage while decreasing current, minimizing losses over hundreds of miles.

For example, during a recent project for a European wind farm, our team installed a custom step-up transformer that converted 33 kV generated by the turbines to 400 kV for grid integration. The result? A 28% reduction in energy loss compared to the client’s previous system, translating to annual savings of over €120,000. Key specs for step-up transformers include:

- Primary Coil: Fewer turns, lower voltage, higher current

- Secondary Coil: More turns, higher voltage, lower current

- Typical Applications: Power plants, wind/solar farms, transmission substations

Step-Down Transformers: Delivering Safe, Usable Power

Once electricity reaches distribution substations, step-down transformers reduce high transmission voltages (e.g., 400 kV, 132 kV) to levels safe for end-users. Residential areas typically receive 240/120 V, while industrial facilities may use 480 V or 600 V depending on their needs.

A memorable substation upgrade project in a U.S. suburban community highlighted the importance of precise step-down regulation. We replaced a 30-year-old transformer with a modern unit featuring multiple taps (adjustable coil turns) that fine-tuned output from 12 kV to 240 V. The upgrade eliminated voltage fluctuations that had been causing frequent appliance failures, reducing service calls by 60% for the local utility. Critical features of step-down transformers include:

- Secondary Coil: Fewer turns than the primary, lower voltage output

- Higher Secondary Current: Enables power delivery to multiple users

- Tap Changers: Allow for ±5% or ±10% voltage adjustment to adapt to load changes

Minimizing Energy Losses: The Pursuit of Efficiency

No transformer is 100% efficient—some energy is lost as heat in the core (hysteresis and eddy current losses) and windings (copper losses). Modern transformer design focuses on reducing these losses through:

- Amorphous Metal Cores: These non-crystalline alloys reduce core losses by up to 70% compared to traditional silicon steel.

- High-Conductivity Copper Windings: Minimize copper losses by reducing electrical resistance.

- Optimized Core Design: Reduces magnetic flux leakage and improves energy transfer.

In a recent industrial project for a automotive manufacturing plant, we installed high-efficiency transformers with amorphous cores. The units cut annual energy losses by 180,000 kWh—equivalent to powering 15 average homes—saving the client over $20,000 in utility costs per year.

Transformers as Grid Stability Guardians: Maintaining Reliable Voltage

Have you ever noticed how your lights don’t flicker when your neighbor turns on their air conditioner or a local factory fires up its machinery? That’s grid stability in action—and transformers are the unsung heroes keeping voltage within safe, consistent ranges. Voltage fluctuations (too high or too low) can damage equipment, disrupt operations, and even cause blackouts. Transformers mitigate these risks through real-time regulation and adaptive technologies.

Over my career, I’ve responded to countless grid emergencies where transformers prevented catastrophic failures. During a 2022 heatwave in the Southwest U.S., a sudden surge in air conditioner use pushed grid load to 95% capacity. Thanks to transformers equipped with on-load tap changers (OLTCs), voltage levels remained stable—avoiding the brownouts that plagued neighboring regions. Let’s explore the key technologies that make this possible:

On-Load Tap Changers (OLTCs): Real-Time Voltage Adjustment

OLTCs are the workhorses of grid stability, allowing transformers to adjust voltage without interrupting power flow. Unlike off-load tap changers (which require the transformer to be disconnected), OLTCs operate while the unit is energized—making them critical for handling dynamic load changes.

Key features of modern OLTCs include:

- Automatic Operation: Sensors monitor voltage and current, triggering tap changes in milliseconds.

- Multiple Tap Positions: Most OLTCs offer 16–32 taps, enabling precise voltage fine-tuning (typically ±10% of nominal voltage).

- Remote Monitoring: Integrate with SCADA systems for centralized control and predictive maintenance.

In a substation upgrade for a major city’s downtown grid, we installed OLTC-equipped transformers that reduced voltage deviation from ±5% to ±1%. The improvement was immediate: commercial buildings reported fewer IT equipment failures, and residential customers no longer experienced dimming lights during peak hours.

Voltage Regulators: Specialized Stability for Targeted Applications

While OLTCs are integrated into transformers, standalone voltage regulators provide focused stability for specific parts of the grid. They come in three primary types, each tailored to unique use cases:

| Type | Function | Application |

|---|---|---|

| Step Voltage Regulators | Adjust voltage in discrete steps (typically 32 steps) | Distribution lines serving residential/light commercial areas |

| Induction Voltage Regulators | Deliver smooth, continuous voltage control | Industrial facilities with sensitive machinery (e.g., manufacturing lines) |

| Electronic Voltage Regulators | Use power electronics for ultra-precise, rapid adjustments | Data centers, medical facilities, and tech hubs with critical loads |

A recent smart grid project in a mid-sized city integrated a network of induction voltage regulators across industrial zones. The regulators communicated with each other via IoT sensors, optimizing voltage levels based on real-time load data. The result? A 25% reduction in reactive power consumption and a 12% improvement in overall grid efficiency.

Reactive Power Compensation: Balancing the Grid’s “Invisible Load”

Reactive power (measured in volt-amperes reactive, VARs) is the “hidden” component of electricity that doesn’t perform useful work but is essential for maintaining voltage stability. Transformers work alongside reactive power compensation devices to balance VARs and prevent voltage collapse.

Common compensation technologies include:

- Capacitor Banks: Provide reactive power to boost voltage during high-load periods.

- Static VAR Compensators (SVCs): Use power electronics to rapidly adjust reactive power (response time <20ms).

- Synchronous Condensers: Rotating machines that deliver dynamic reactive power support—ideal for grids with high renewable penetration.

I helped design a reactive power compensation system for a large industrial park in Asia, where 10+ factories operated high-inductance machinery (e.g., motors, welders). By pairing transformers with SVCs, we improved the grid’s power factor from 0.78 to 0.95—reducing energy costs for the park’s tenants by an average of 18% and eliminating voltage sags that had disrupted production.

Diverse Transformer Types: Tailored Solutions for Every Electrical Need

In the transformer industry, “one size fits all” is a myth. Electrical systems vary wildly—from a small solar inverter’s 1kVA transformer to a utility substation’s 1000 MVA unit—and each requires a specialized design to deliver optimal performance. Over the years, I’ve worked with nearly every type of transformer, from pole-mounted distribution units to custom traction transformers for light rail systems. Let’s explore the most common types and their unique applications:

Power Transformers: Grid-Level Voltage Conversion

Power transformers are the giants of the industry, designed for high-voltage, high-capacity applications at power plants and transmission substations. They’re typically rated above 500 kVA and operate at voltages exceeding 69 kV—some even handling 1000 kV for ultra-long-distance transmission.

Key characteristics:

- Massive Size: A 1000 MVA power transformer can weigh over 200 tons and occupy the space of a small house.

- Low Losses: Optimized for 24/7 operation, with efficiency ratings of 99.5% or higher.

- Custom Design: Each unit is engineered for specific voltage ratios and environmental conditions (e.g., extreme temperatures, coastal humidity).

One of my most memorable projects involved installing a 800 MVA power transformer at a hydroelectric plant in South America. The unit was transported by barge and required a custom-built foundation to support its weight. After commissioning, it converted 18 kV generator output to 500 kV for transmission—powering over 2 million homes across three countries.

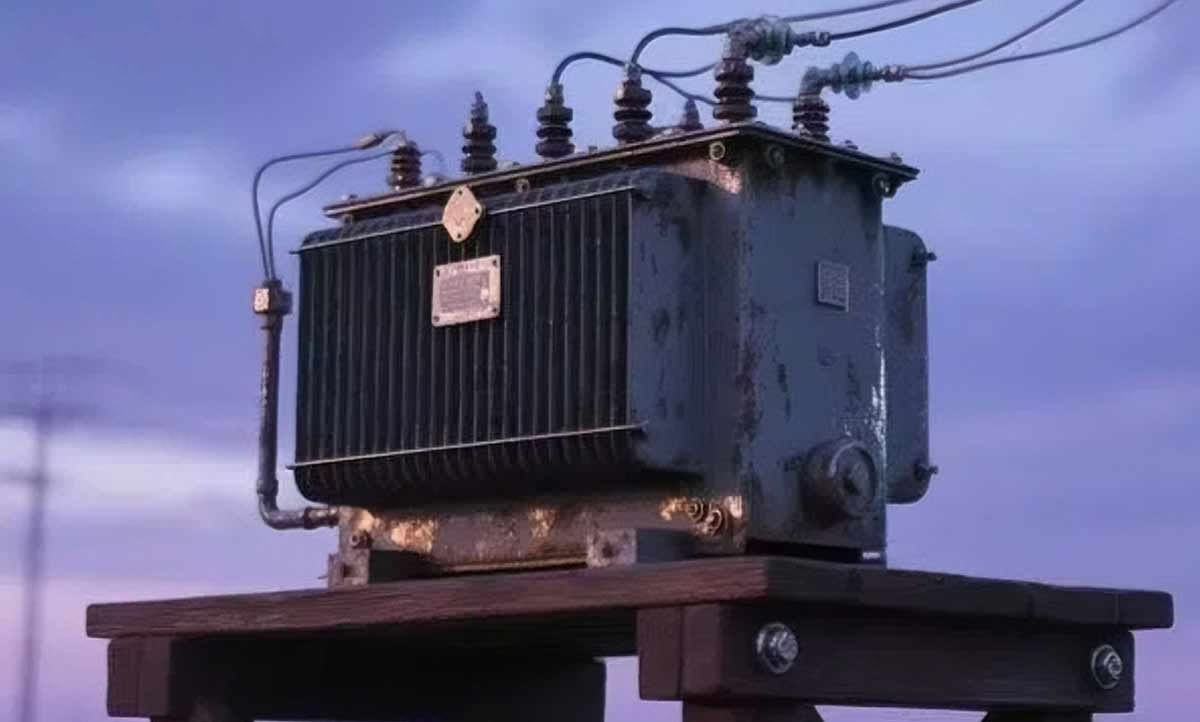

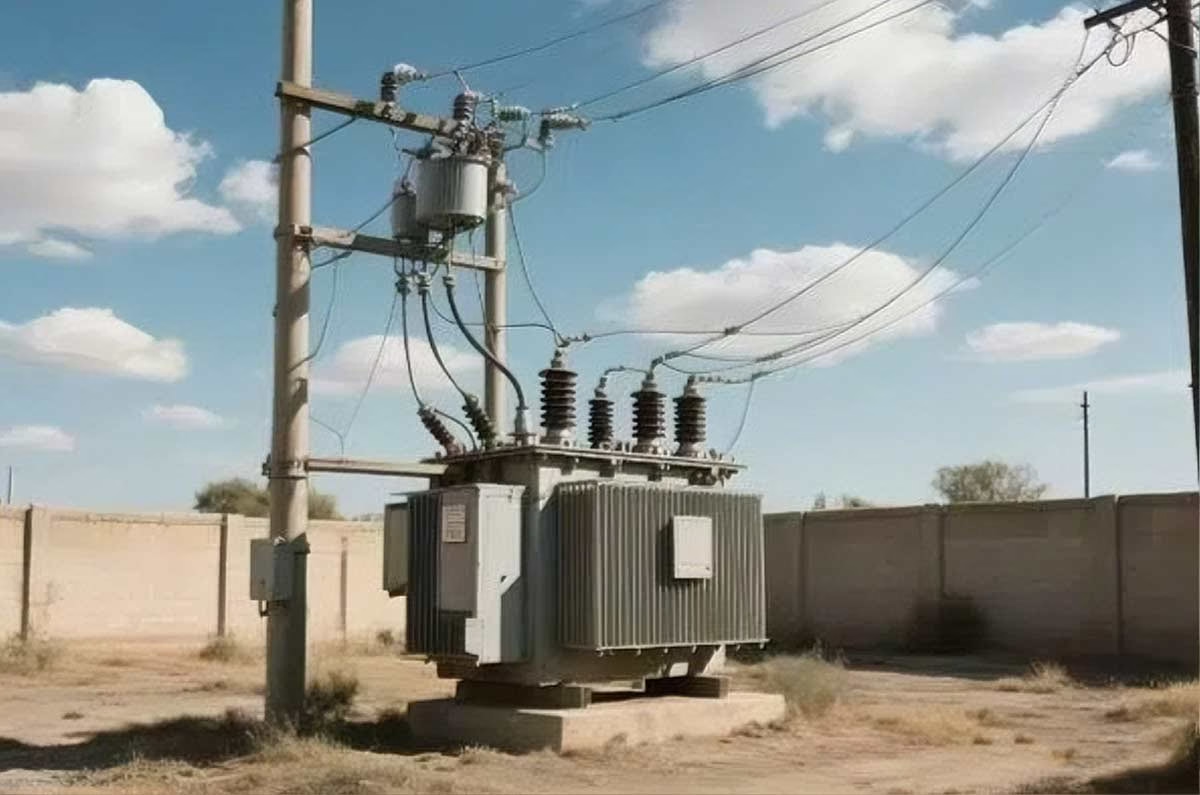

Distribution Transformers: Bringing Power to Neighborhoods

Distribution transformers are the final link in the electrical chain, stepping down voltage from distribution lines (12 kV–34.5 kV) to usable levels for homes and businesses. They’re the most visible type of transformer, often mounted on utility poles, pad-mounted on the ground, or installed underground in urban areas.

| Mounting Type | Typical Rating | Use Case |

|---|---|---|

| Pole-Mounted | 5–150 kVA | Residential neighborhoods, rural areas |

| Pad-Mounted | 75–5000 kVA | Commercial districts, industrial parks, suburban developments |

| Underground | 75–3000 kVA | Urban centers, historic districts, and areas with strict aesthetic requirements |

In a recent urban renewal project for a city’s downtown area, we installed 24 pad-mounted distribution transformers. Each unit was designed to fit within a compact, weather-resistant enclosure and featured noise-reducing technology (critical for densely populated areas). The transformers stepped down 12 kV to 240/120 V, powering new apartments, restaurants, and office buildings while maintaining compliance with local noise and safety regulations.

Isolation Transformers: Safety and Noise Reduction

Isolation transformers provide electrical separation between the input (grid) and output (equipment), preventing ground loops and electric shock. They’re critical for applications where safety and noise reduction are paramount.

Key benefits:

- Galvanic Isolation: Breaks the direct electrical path between the grid and equipment, reducing shock hazards.

- Noise Suppression: Eliminates common-mode noise (interference from other electrical devices) that can disrupt sensitive electronics.

- Fault Isolation: Contains electrical faults to a single device or system, preventing widespread outages.

I designed an isolation transformer system for a hospital’s operating rooms in Europe, where patient safety and equipment reliability are non-negotiable. The transformers isolated medical devices (e.g., MRI machines, surgical tools) from the grid, eliminating electrical interference and reducing the risk of ground loop shocks. Post-installation, the hospital reported zero equipment-related disruptions during surgeries—a critical win for patient care.

Auto-Transformers: Efficient Voltage Adjustment for Close Ratios

Auto-transformers differ from traditional two-winding transformers by using a single winding for both primary and secondary circuits. This design makes them smaller, lighter, and more efficient than conventional transformers—ideal for applications where voltage ratios are close (e.g., 240 V to 480 V).

Common uses:

- Voltage boosting in distribution systems (e.g., increasing 4 kV to 12 kV for rural electrification).

- Voltage matching in industrial processes (e.g., aligning 380 V equipment with a 400 V grid).

- Starting large motors (reducing inrush current to protect the grid).

In a rural electrification project in Africa, we used auto-transformers to boost the grid voltage from 4 kV to 12 kV. The compact design allowed for easy transportation to remote villages, and the efficiency gains reduced energy losses by 35% compared to traditional transformers. Over 5,000 homes gained access to reliable electricity—transforming local communities and supporting small businesses.

Special Application Transformers: Meeting Unique Industry Needs

Beyond standard types, specialized transformers cater to niche applications that require custom designs. Some of the most common include:

- Rectifier Transformers: Convert AC to DC for industrial processes (e.g., electroplating, battery charging) and renewable energy systems (e.g., solar inverters).

- Furnace Transformers: Handle high currents (up to 10,000 A) for industrial heating applications (e.g., arc furnaces for steel production).

- Traction Transformers: Power electric trains, subways, and light rail systems—designed to withstand vibration, temperature extremes, and frequent load changes.

Recently, our team developed custom traction transformers for a light rail system in a major U.S. city. The units had to handle rapid voltage fluctuations (from 750 V DC to 12 kV AC) and operate in tight spaces under train platforms. By using lightweight materials and shock-resistant designs, we met the client’s requirements for reliability and space efficiency—helping the system reduce downtime by 40% compared to its previous transformers.

Protecting Electrical Equipment: How Transformers Safeguard Critical Assets

Every year, voltage fluctuations and power surges cause billions of dollars in damage to electrical equipment—from household appliances to industrial machinery. Transformers act as the first line of defense, shielding devices from harm while ensuring consistent power quality. Over my career, I’ve seen transformers save everything from $100,000 industrial robots to life-saving medical equipment. Let’s explore how they provide this protection:

Voltage Stabilization: Preventing Damage from Over/Undervoltage

Overvoltage (voltage higher than the nominal level) can fry circuits and shorten the lifespan of equipment, while undervoltage (too low voltage) can cause motors to overheat and electronics to malfunction. Transformers prevent these issues by maintaining voltage within a safe range (typically ±5% of nominal).

Key stabilization technologies:

- Load Tap Changers (LTCs): Adjust voltage in response to load changes (e.g., increasing voltage during peak demand).

- Automatic Voltage Stabilizers (AVSs): Integrate with transformers to provide rapid correction for sudden fluctuations (response time <1ms).

- Digital Control Systems: Use algorithms to predict load changes and adjust voltage proactively.

A project for a semiconductor manufacturing facility highlighted the importance of precise voltage stabilization. The client’s equipment (which required voltage stability of ±0.5%) was experiencing frequent failures due to grid fluctuations. We installed transformers with digital AVS systems, reducing voltage deviation to ±0.1%. The result? A 40% drop in equipment downtime and $2 million in annual savings from reduced repairs and lost production.

Transient Suppression: Shielding Against Power Surges

Transients (sudden voltage spikes) are caused by lightning strikes, utility switching, or equipment malfunctions. Even a brief surge (as short as 1 microsecond) can destroy sensitive electronics. Transformers work with surge arresters and snubber circuits to suppress these transients:

| Suppression Method | Function | Application |

|---|---|---|

| Surge Arresters | Divert excess voltage to ground via a nonlinear resistor | Outdoor transformers, transmission lines, and lightning-prone areas |

| Snubber Circuits | Absorb voltage spikes using capacitors and resistors | Industrial equipment with inductive loads (e.g., motors, solenoids) |

| Neutral Grounding Resistors (NGRs) | Limit fault currents during transients, preventing equipment damage | Industrial plants, data centers, and large commercial buildings |

During a severe thunderstorm in the Midwest U.S., a data center we worked with was struck by lightning. Thanks to surge arresters integrated with their transformers, the excess voltage was diverted to ground—protecting $5 million worth of servers and storage equipment. The data center experienced zero downtime, while neighboring facilities without similar protection were offline for 12+ hours.

Galvanic Isolation: Breaking Dangerous Electrical Paths

Galvanic isolation separates the input and output circuits of a transformer, preventing ground loops and electric shock. Ground loops (unintended current paths between two ground points) can cause noise, equipment malfunctions, and safety hazards. Isolation transformers eliminate this risk by breaking the direct electrical connection.

Key benefits of galvanic isolation:

- Safety: Reduces the risk of electric shock for users and technicians.

- Noise Reduction: Blocks common-mode noise (interference from other devices) that can disrupt sensitive electronics.

- Fault Isolation: Contains electrical faults to a single device, preventing them from spreading to the wider grid.

In a hospital’s intensive care unit (ICU), we installed isolation transformers to protect patients and medical equipment. The transformers isolated ventilators, heart monitors, and other critical devices from the grid, eliminating ground loops and reducing electrical interference. The hospital reported a 30% reduction in equipment malfunctions, improving patient safety and care quality.

Harmonic Mitigation: Cleaning Up Power Quality

Harmonics are unwanted frequencies in the electrical grid caused by nonlinear loads (e.g., computers, LED lights, variable-frequency drives). They can distort voltage waveforms, increase energy losses, and damage equipment. Transformers address this issue through specialized designs and integration with harmonic filters:

- K-Factor Transformers: Designed to handle harmonic loads, with reinforced windings and cores that resist overheating.

- Phase-Shifting Transformers: Cancel out specific harmonics by shifting the phase of the current.

- Active Harmonic Filters: Work alongside transformers to remove harmonics in real time, improving power quality.

A project for a large office building in Dubai demonstrated the impact of harmonic mitigation. The building’s IT equipment and LED lighting were causing significant harmonic distortion (THD >15%), leading to overheating in transformers and frequent computer crashes. We installed K-factor transformers paired with active harmonic filters, reducing THD to <5% (the industry standard). The improvement was immediate: transformer temperatures dropped by 20°C, and IT equipment failures decreased by 50%.

Smart Voltage Control: Advanced Transformer Technologies Shaping the Future Grid

As the world shifts to renewable energy and smart cities, the electrical grid faces new challenges: variable power generation (from solar/wind), increasing electric vehicle (EV) adoption, and growing demand for real-time power management. Smart transformers—equipped with sensors, AI, and connectivity—are rising to meet these challenges, revolutionizing how we regulate and distribute electricity.

I’ve been fortunate to work on the cutting edge of smart transformer technology, from pilot projects to large-scale grid modernization initiatives. The advancements I’ve seen—from real-time monitoring to AI-driven optimization—are transforming the grid into a more efficient, resilient, and sustainable system. Let’s explore the key innovations driving this revolution:

Real-Time Monitoring and Predictive Analytics

Smart transformers are equipped with a network of sensors that monitor voltage, current, temperature, oil level (for liquid-filled units), and vibration in real time. This data is transmitted to cloud-based platforms, where predictive analytics algorithms identify potential issues before they cause failures.

Key monitoring capabilities:

- Condition Monitoring: Track transformer health (e.g., winding temperature, oil moisture) to schedule maintenance proactively.

- Load Profiling: Analyze energy usage patterns to optimize voltage levels and reduce losses.

- Grid Event Detection: Identify faults (e.g., short circuits, voltage sags) and trigger rapid responses.

In a smart city project in Singapore, we installed 50+ smart transformers with advanced monitoring systems. The sensors detected a potential winding failure in one unit—allowing the utility to replace the part during a scheduled outage, avoiding a costly unplanned blackout. Over the first year, the project reduced maintenance costs by 30% and improved transformer reliability by 25%.

Adaptive Voltage Optimization: AI-Driven Efficiency

Adaptive voltage optimization (AVO) uses machine learning algorithms to adjust voltage levels based on real-time load data, historical patterns, and grid conditions. Unlike traditional transformers (which operate at fixed voltage levels), smart transformers with AVO can optimize voltage for efficiency without sacrificing reliability.

Key features of AVO:

- Dynamic Set Points: Adjust target voltage levels throughout the day (e.g., lower voltage during low demand to reduce losses).

- Demand Response Integration: Coordinate with utility demand response programs to reduce peak loads (e.g., lowering voltage for non-critical loads during high demand).

- Self-Learning Algorithms: Improve optimization over time by analyzing past performance and load patterns.

A pilot program for a U.S. utility demonstrated the power of AVO. Smart transformers in a residential neighborhood reduced voltage by 3% during off-peak hours, cutting energy consumption by 4% while maintaining customer satisfaction (no reports of dimming lights or equipment issues). Scaled across the utility’s service area, this would translate to annual savings of $12 million and a 15,000-ton reduction in carbon emissions.

Distributed Intelligence: Decentralized Grid Management

Traditional grids rely on central control systems, which can be slow to respond to local issues. Smart transformers feature distributed intelligence—allowing them to make autonomous decisions without waiting for central commands. They can also communicate with other transformers and grid devices (e.g., solar inverters, EV chargers) to optimize performance across the system.

Key benefits of distributed intelligence:

- Faster Response Times: Local decisions reduce latency, critical for handling sudden load changes or faults.

- Scalability: Easily integrate new devices (e.g., rooftop solar, EV charging stations) without overloading central systems.

- Resilience: Decentralized control means the grid can continue operating even if central systems fail.

In a grid modernization project for a European country, we deployed 200+ intelligent transformers across a rural region with high solar penetration. The transformers communicated with each other to balance solar generation and load, reducing curtailment (wasted solar energy) by 35%. They also autonomously adjusted voltage to accommodate EV charging spikes—ensuring reliable power for both EV owners and other customers.

Renewable Energy Integration: Bridging the Gap Between Generation and Grid

Renewable energy sources (solar, wind) are variable by nature—output fluctuates with weather conditions, creating challenges for grid stability. Smart transformers address this by managing bi-directional power flow, smoothing out generation peaks and valleys, and ensuring compatibility with the grid.

Key integration capabilities:

- Bi-Directional Power Flow Management: Handle electricity flowing from the grid to renewable sources (for startup) and from sources to the grid (for generation).

- Ramp Rate Control: Limit sudden changes in renewable output (e.g., when clouds pass over a solar farm) to prevent voltage fluctuations.

- Voltage Ride-Through: Keep renewable sources connected during grid disturbances, ensuring continuous power delivery.

A project integrating a 500 MW solar farm into the Australian grid showcased these capabilities. Smart transformers at the farm’s substation managed the variable solar output, reducing voltage fluctuations from ±10% to ±2%. This allowed the farm to connect to the grid without disrupting service—helping Australia meet its renewable energy targets while maintaining grid reliability.

Conclusion

Electrical transformers are far more than simple voltage converters—they’re the backbone of modern electrical systems, ensuring efficient power transmission, grid stability, and equipment protection. From the massive power transformers that connect power plants to the grid to the compact distribution units that power our homes, every transformer plays a critical role in keeping our world running.

As the industry evolves, smart technologies, advanced materials, and custom designs are pushing transformers to new heights—enabling the integration of renewable energy, supporting smart cities, and delivering unprecedented levels of efficiency and reliability. For manufacturers like us, the goal remains clear: to engineer transformers that meet the unique needs of each application, from rural electrification to industrial automation, while contributing to a more sustainable, connected future.

Whether you’re a utility company upgrading your grid, an industrial facility seeking to improve efficiency, or a community looking to expand access to electricity, the right transformer can make all the difference. With decades of experience in designing and manufacturing custom transformers, we’re proud to be part of this journey—powering progress one transformer at a time.