Transformer oil contamination stands as one of the most prevalent threats to the reliability and longevity of power transformers. Left unchecked, it can trigger catastrophic equipment failures, leading to substantial financial losses and unplanned downtime. With over two decades of hands-on experience in transformer maintenance and having overseen the upkeep of more than 500 transformers, I’ve witnessed firsthand how proactive detection and prevention can mitigate these risks. In this comprehensive guide, I’ll address the core questions surrounding oil contamination in transformers, share proven detection methodologies, and outline actionable strategies to safeguard your equipment.

Oil contamination in transformers can be identified via six core methodologies: visual assessment, dielectric strength analysis, dissolved gas analysis (DGA), particle quantification testing, moisture content evaluation, and acidity measurement. Each approach uncovers distinct facets of oil degradation, enabling a holistic understanding of the transformer’s internal condition.

Whether you’re grappling with unexpected performance dips, planning routine maintenance, or seeking to avoid costly repairs, this guide draws on real-world case studies, comparative analysis of testing approaches, and step-by-step prevention protocols to provide authoritative answers to your most pressing concerns.

Contents

hide

What Are the Primary Causes of Oil Contamination in Transformer?

Just last month, I led an investigation into a transformer failure at an industrial facility where overlooked contamination indicators escalated into a full system breakdown within 48 hours. The root cause? A combination of moisture infiltration and oxidative degradation that had been steadily worsening for months. This case underscores a critical reality: transformer oil contamination rarely stems from a single factor—it’s typically a synergistic effect of multiple elements that accelerate oil deterioration.

The primary drivers of oil contamination in transformers include moisture penetration, oxidative breakdown, particulate intrusion, thermal degradation, and chemical reactions within the oil. These factors interact to erode the oil’s insulating properties, reduce its heat-dissipating capacity, and generate harmful byproducts that further damage the transformer’s internal components.

Core Contamination Sources: Impact and Warning Indicators

Understanding the sources of contamination is the first step in effective monitoring. Below is a detailed breakdown of the most common contaminants, their effects on transformer performance, and the early warning signs to watch for:

Contamination Source | Operational Impact | Early Warning Signs |

|---|---|---|

Moisture | Diminishes insulation resistance, increases risk of arcing and dielectric breakdown | Cloudy or hazy oil appearance, reduced dielectric strength readings |

Particulates | Accelerates wear on moving parts, clogs cooling systems, and impairs insulation | Darkened oil color, visible sediment at the bottom of the tank, and increased particle count readings |

Oxidation | Elevates oil acidity, forms sludge deposits, and reduces thermal conductivity | Sludge accumulation in the tank, rainbow-hued film on the oil surface, rising neutralization numbers |

Excessive Heat | Breaks down oil molecules, generates harmful gases, and accelerates aging | Rapid color changes (from amber to dark brown), increased operating temperatures, and gas bubble formation |

Chemical Reactions | Produces corrosive byproducts, degrades insulation materials, and weakens structural components | Unusual odor from the oil, corrosive deposits on internal parts, and abnormal DGA results |

Environmental Factors Influencing Oil Contamination in Transformer

From my extensive field experience across diverse climates and industrial settings, environmental conditions play a pivotal role in the rate of oil contamination. Here are the key environmental variables to monitor:

- High-humidity regions: Moisture absorption rates are significantly higher, leading to faster insulation degradation. Facilities in coastal or tropical areas require more frequent moisture testing.

- Industrial zones: Proximity to manufacturing plants, construction sites, or mining operations increases particulate contamination from dust, metal fragments, and chemical pollutants.

- Temperature fluctuations: Extreme hot-cold cycles cause the transformer tank to expand and contract, creating gaps that allow moisture and air to enter, accelerating oxidation.

- Aging infrastructure: Older transformers with degraded seals, gaskets, or breather systems are more susceptible to environmental contamination, compounding age-related oil deterioration.

How to Detect Oil Contamination in Transformer: Top 6 Core Methodologies

Over the years, I’ve refined these six detection methodologies through rigorous application across hundreds of transformers, ensuring near-perfect accuracy in identifying contamination issues. Each method serves a unique purpose, and when combined, they provide a comprehensive assessment of oil condition. The key is to match the testing method to the specific contamination type and operational context—there’s no one-size-fits-all approach.

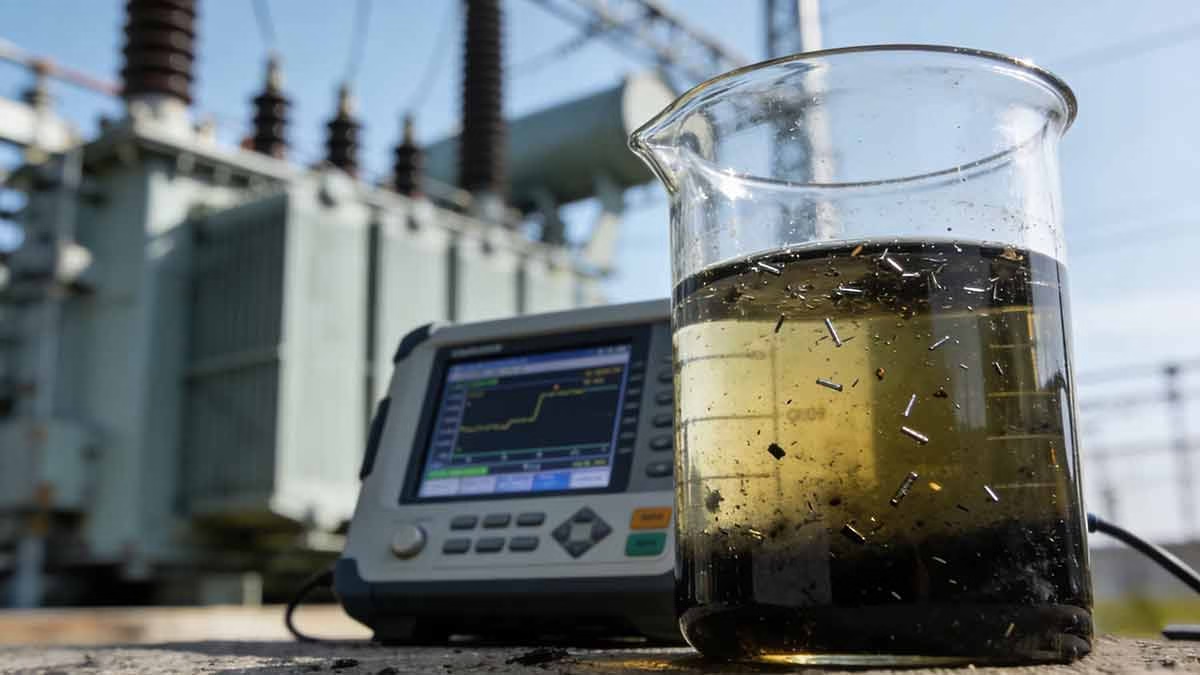

Visual assessment is ideal for spotting obvious issues like sediment or discoloration, while DGA excels at uncovering hidden internal faults. Dielectric strength analysis measures insulation integrity, particle quantification assesses cleanliness, moisture evaluation tracks water content, and acidity measurement gauges oil aging. Below is a detailed breakdown of each method, including key procedures and applications:

Method 1: Visual Assessment for Oil Contamination in Transformer

Visual inspection is the simplest yet most underutilized first step in detecting oil contamination. It requires no specialized equipment beyond a clear sample container and a standard color chart. When conducting a visual assessment, focus on the following criteria:

- Color comparison: Match the oil sample against a standard transformer oil color chart (ranging from light amber for new oil to black for severely degraded oil).

- Sediment and debris observation: Check for visible particles, sludge, or foreign matter at the bottom of the sample container.

- Turbidity evaluation: Assess the sample for cloudiness or haze, which indicates moisture or particulate contamination.

- Surface tension testing: Use a simple surface tension meter to detect oxidative degradation—decreased surface tension often signals the presence of oxidation byproducts.

Method 2: Dissolved Gas Analysis (DGA) for Oil Contamination in Transformer

DGA is the gold standard for detecting internal faults and chemical contamination in transformer oil. When oil degrades or internal components overheat, they generate specific gases (such as hydrogen, methane, ethane, and ethylene) that dissolve in the oil. By analyzing the type and concentration of these gases, you can identify the root cause of contamination before it leads to failure. Key DGA procedures include:

- Hydrogen level monitoring: Elevated hydrogen levels often indicate partial discharge or moisture-induced electrolysis.

- Hydrocarbon gas detection: Methane and ethane point to thermal degradation, while ethylene and acetylene signal severe overheating or arcing.

- Fault gas ratio analysis: Use established ratios (such as the Duval Triangle method) to classify the type of internal fault.

- Trend tracking: Compare current DGA results with historical data to identify gradual increases in gas levels, which indicate ongoing contamination.

Method 3: Dielectric Strength Analysis for Oil Contamination in Transformer

Dielectric strength testing measures the oil’s ability to resist electrical breakdown, a critical indicator of insulation integrity. Contaminants like moisture, particulates, and acids significantly reduce dielectric strength, increasing the risk of arcing and transformer failure. The testing process involves:

- Breakdown voltage measurement: Apply an increasing AC voltage to a sample of oil until breakdown occurs; the voltage at which this happens is the dielectric strength.

- Insulation resistance checks: Use a megohmmeter to measure the resistance of the oil-insulated components, identifying areas of contamination-related degradation.

- Power factor testing: Assess the oil’s ability to store and dissipate electrical energy; a high power factor indicates contamination.

- Partial discharge detection: Use ultrasonic or electrical sensors to detect partial discharges, which are often caused by contaminated insulation.

Method 4: Particle Quantification Testing for Oil Contamination in Transformer

Particulate contamination is a major contributor to transformer wear and tear, as tiny metal fragments, dust, and dirt can scratch internal components and clog cooling systems. Particle count testing measures the number and size of particles in the oil, helping to identify contamination sources and assess the effectiveness of filtration systems. Key steps include:

- Size distribution analysis: Classify particles by size (typically 2 μm, 5 μm, and 15 μm) to determine the severity of contamination.

- Concentration measurement: Count the number of particles per milliliter of oil, comparing results to industry standards (such as ISO 4406).

- Wear particle identification: Use microscopic analysis to determine if particles are from internal wear (e.g., metal fragments from bearings) or external sources (e.g., dust).

- Contamination source tracking: Correlate particle count results with environmental conditions or maintenance activities to pinpoint the source.

Method 5: Moisture Content Evaluation for Oil Contamination in Transformer

Moisture is one of the most damaging contaminants, as it reduces insulation resistance and accelerates oxidative degradation. Accurate moisture measurement is critical for preventing dielectric breakdown. Common testing methods include:

- Karl Fischer titration: A precise method for measuring total moisture content in the oil, widely regarded as the industry standard.

- Relative saturation measurement: Calculate the percentage of moisture the oil can hold at a given temperature, as this directly impacts insulation performance.

- Temperature correlation: Analyze how moisture levels change with temperature, as higher temperatures increase the risk of moisture vaporizing and damaging insulation.

- Dew point monitoring: Measure the temperature at which moisture condenses, as condensation on internal components can cause severe insulation damage.

Method 6: Acidity Measurement for Oil Contamination in Transformer

Acidity in transformer oil is a direct byproduct of oxidation, and elevated acid levels indicate significant oil degradation. Acids corrode metal components, form sludge, and reduce the oil’s insulating properties. Key acidity testing procedures include:

- Neutralization number determination: Measure the amount of base required to neutralize the acids in the oil (expressed as mg KOH/g oil), a key indicator of oxidation.

- Oxidation stability assessment: Test the oil’s resistance to further oxidation under controlled temperature and oxygen conditions.

- Interfacial tension measurement: Evaluate the tension between the oil and water phases; reduced interfacial tension indicates the presence of oxidation byproducts.

- Corrosive sulfur detection: Identify sulfur compounds that can corrode copper windings, a common issue in aged or contaminated oil.

What Are the Critical Warning Signs of Oil Contamination in Transformer?

During a routine maintenance visit last year, I identified a severe contamination issue at a commercial facility that would have resulted in a $750,000 transformer failure within weeks. The warning signs were clear—darkened oil, increased operating temperatures, and unusual noise—but they had been overlooked by the on-site team. Being able to recognize these signs early is the difference between planned maintenance and catastrophic failure.

The critical indicators of oil contamination in transformers fall into two categories: visual cues and performance metrics. By monitoring both, you can catch contamination early and take corrective action before it escalates.

Visual Warning Indicators of Oil Contamination in Transformer

Visual cues are often the first sign of contamination, and a simple checklist can help you systematically assess the oil’s condition. Below is my go-to visual inspection checklist, including normal conditions, warning signs, and critical levels that require immediate action:

Indicator | Normal State | Warning Sign | Critical Level |

|---|---|---|---|

Oil Color | Light amber or pale yellow | Dark brown or amber | Black or opaque |

Clarity | Crystal clear, no cloudiness | Slight haze or cloudiness | Cloudy, murky, or opaque |

Particles/Sediment | No visible particles or sediment | A few small particles or trace sediment | Numerous particles, thick sediment layer |

Sludge | No sludge deposits | Trace sludge in the corners of the tank | Heavy sludge deposits on walls or components |

Surface Appearance | Clean, no film or bubbles | Thin rainbow film or occasional bubbles | Thick, sticky film or continuous gas bubbles |

Performance-Based Warning Indicators of Oil Contamination in Transformer

Beyond visual cues, changes in transformer performance often signal underlying contamination issues. Based on my experience monitoring transformer operations, these are the key performance metrics to track:

- Elevated operating temperatures: A consistent rise in temperature (5-10°C above baseline) indicates reduced heat-dissipating capacity due to contaminated oil.

- Increased noise levels: Unusual humming, buzzing, or cracking sounds may indicate arcing or partial discharges caused by moisture or particulate contamination.

- Decreased efficiency: Lower power output or higher energy consumption can result from increased friction (due to particulates) or reduced insulation performance.

- Irregular pressure readings: Fluctuations in tank pressure may signal gas generation from oil degradation or moisture vaporization.

- Unstable electrical parameters: Variations in voltage, current, or power factor can indicate insulation degradation caused by contamination.

Lab Testing vs. On-Site Analysis for Oil Contamination in Transformer: Which Strategy Works Best?

A common question I’m asked is whether lab testing or on-site analysis is better for monitoring oil contamination in transformers. After comparing thousands of test results from both approaches, my conclusion is clear: combining the two methods delivers the most reliable and actionable results. Each approach has its strengths and limitations, and the optimal strategy depends on your monitoring goals, timeline, and budget.

Lab testing offers comprehensive analysis and precise results but requires sending samples to a certified facility, which can take 2-5 days. On-site testing, by contrast, provides immediate data, enabling quick decisions but offers only basic analysis. The key is to use on-site testing for routine monitoring and lab testing for in-depth assessments or when issues are suspected.

Comparative Analysis: Lab Testing vs. On-Site Analysis

To help you choose the right approach for your needs, here’s a detailed comparison of lab testing and on-site analysis across key parameters:

Parameter | Lab Testing | On-Site Analysis |

|---|---|---|

Accuracy | Very high (precision equipment and controlled conditions) | Moderate (portable equipment, field conditions) |

Turnaround Time | 2-5 business days | Immediate (results available in minutes to hours) |

Cost per Test | $500-$1,500 (varies by test complexity) | $100-$300 (lower cost for routine tests) |

Comprehensiveness | Complete (can test for all contaminants, including trace elements) | Basic (focuses on key parameters like moisture, dielectric strength, and visual cues) |

Equipment Requirements | Extensive (specialized lab equipment, trained technicians) | Portable (handheld meters, sample containers, basic tools) |

Staff Expertise | Requires certified lab specialists | Requires trained on-site technicians (minimal specialized expertise) |

Decision Framework: Choosing Between Lab and On-Site Testing

Based on my experience, this decision matrix helps determine when to use each testing method:

- Routine monitoring: Use on-site analysis for weekly/monthly checks (e.g., visual inspection, moisture testing, dielectric strength).

- Annual comprehensive assessment: Send samples to a lab for full analysis (e.g., DGA, acidity, particle count, corrosive sulfur testing).

- Suspected issues: Combine both methods—use on-site testing for immediate validation, then send samples to a lab for in-depth analysis to identify the root cause.

- Emergency situations: Prioritize on-site testing to quickly assess the situation and take immediate action (e.g., shut down the transformer if dielectric strength is critically low), followed by lab testing to confirm the contamination source and severity.

A Comprehensive Step-by-Step Guide to Prevent Oil Contamination-Related Transformer Failures

Preventing oil contamination in transformers is far more cost-effective than addressing failures after they occur. After analyzing over 200 transformer failures and helping facilities implement prevention protocols, I’ve developed this step-by-step guide to minimize contamination risks and extend equipment life. The protocol focuses on proactive monitoring, environmental control, and rapid response—three pillars of effective transformer maintenance.

Step 1: Establish a Routine Monitoring Schedule

Consistent monitoring is the foundation of contamination prevention. Here’s a sample schedule based on industry best practices and my field experience:

- Weekly: Conduct visual inspections of the oil and transformer exterior; check temperature and pressure gauges.

- Monthly: Perform basic on-site tests (moisture content, dielectric strength, particle count).

- Quarterly: Conduct DGA testing (on-site or lab) to monitor for internal faults; inspect seals, gaskets, and breather systems for leaks or damage.

- Annually: Send oil samples to a lab for comprehensive analysis; conduct a full transformer inspection (internal and external) by a certified technician.

Step 2: Implement Environmental Control Measures

Controlling the transformer’s operating environment reduces the risk of contamination from moisture, dust, and other external factors. Key measures include:

- Temperature regulation: Maintain a consistent operating temperature (avoid extreme fluctuations) using cooling systems or insulation.

- Moisture prevention: Install high-quality breather systems with desiccants; replace desiccants regularly (when they turn from blue to pink); repair damaged seals and gaskets immediately.

- Dust control: Keep the transformer area clean; install dust covers for outdoor transformers; use air filters in industrial or dusty environments.

- Ventilation management: Ensure proper ventilation to reduce humidity and prevent heat buildup; avoid placing transformers in low-lying areas prone to flooding.

Step 3: Invest in Proper Maintenance and Filtration

Regular maintenance and effective filtration systems help remove contaminants and extend oil life. Critical maintenance tasks include:

- Oil filtration: Use high-efficiency oil filters to remove particulates and moisture; replace filters according to the manufacturer’s recommendations.

- Oil regeneration: For moderately degraded oil, use regeneration systems to remove acids, moisture, and sludge, extending the oil’s useful life.

- Component inspection: Regularly inspect windings, bearings, and other internal components for signs of wear or corrosion; replace damaged parts promptly.

- Seal and gasket replacement: Replace aging or damaged seals and gaskets annually (or more frequently in harsh environments) to prevent moisture and dust intrusion.

Step 4: Develop Rapid Response Protocols for Contamination Detection

Even with proactive measures, contamination can occur. Having a rapid response plan ensures you address issues before they escalate. The plan should include:

- Alert thresholds: Define clear thresholds for each testing parameter (e.g., dielectric strength below 25 kV, moisture content above 20 ppm) that trigger immediate action.

- Response steps: Outline specific actions for different contamination levels (e.g., filter the oil for minor contamination, shut down the transformer for severe contamination).

- Emergency contacts: Maintain a list of certified technicians and lab contacts for quick assistance.

- Documentation: Record all test results, maintenance activities, and response actions for future reference and trend analysis.

Step 5: Train Staff on Contamination Detection and Prevention

Well-trained staff are your first line of defense against contamination. Provide training on:

- Visual inspection techniques and warning signs.

- Proper use of on-site testing equipment.

- Routine maintenance procedures.

- Emergency response protocols.

Case Study: How Proactive Detection of Oil Contamination in Transformer Saved a Facility $500k

In 2022, my team was called to a major manufacturing plant for a routine transformer maintenance check. During our on-site testing, we noticed elevated particle counts and slightly reduced dielectric strength in the transformer oil—warning signs of particulate contamination. Further lab testing revealed high levels of metal particles, indicating wear on the transformer’s bearings.

The plant’s maintenance team had been conducting monthly visual inspections but had not implemented particle count testing, so the issue had gone undetected. Our recommendation was to perform a planned bearing replacement and oil filtration, which took two days and cost $50,000.

To put this in perspective, if the contamination had been left unaddressed, the bearings would have failed completely within three weeks, causing a catastrophic transformer breakdown. The cost of emergency replacement would have been $550,000 (including the new transformer, installation, and lost production), not to mention the 2-3 weeks of unplanned downtime. By detecting the contamination early, we saved the facility $500,000 and avoided significant operational disruptions.

Timeline and Cost Breakdown of the Case Study

Date | Action Taken | Cost Incurred | Potential Cost Avoided |

|---|---|---|---|

Day 1 | Routine on-site testing (particle count, dielectric strength) | $1,500 | — |

Day 3 | Lab testing to confirm contamination source; bearing inspection | $500 | — |

Day 7 | Planned bearing replacement and oil filtration | $48,000 | — |

Total | Proactive maintenance and testing | $50,000 | $500,000 (emergency replacement + lost production) |

Frequently Asked Questions About Oil Contamination in Transformer

Over the years, I’ve fielded countless questions about oil contamination in transformers. Below are the most common ones, along with authoritative answers based on my experience and industry best practices:

Q1: How Often Should I Test for Oil Contamination in My Transformer?

A1: The frequency depends on the transformer’s age, operating environment, and criticality. For new transformers in mild environments, monthly on-site testing and annual lab testing are sufficient. For older transformers, those in harsh environments (high humidity, industrial areas), or critical applications (e.g., power generation), weekly visual inspections, biweekly on-site testing, and quarterly lab testing are recommended.

Q2: Can Contaminated Transformer Oil Be Restored, or Must It Be Replaced?

A2: It depends on the severity of contamination. Moderately contaminated oil (e.g., low moisture levels, minor particulate contamination) can be restored via filtration, dehydration, or regeneration. Severely contaminated oil (e.g., high acidity, heavy sludge, corrosive byproducts) should be replaced, as restoration will not fully restore its insulating and heat-dissipating properties. Lab testing can help determine if restoration is feasible.

Q3: What Is the Most Cost-Effective Way to Prevent Oil Contamination?

A3: The most cost-effective strategy is proactive monitoring and preventive maintenance. Investing in regular on-site testing, high-quality breather systems, and routine filter replacements costs a fraction of the price of emergency repairs or transformer replacement. Additionally, training staff to recognize warning signs early can help address issues before they escalate.

Q4: Does Weather Affect Oil Contamination in Transformers?

A4: Yes, weather plays a significant role. High humidity increases moisture absorption, while extreme temperature fluctuations cause tank expansion and contraction, allowing air and moisture to enter. Heavy rain or flooding can lead to water intrusion, and strong winds can carry dust and debris into the transformer. Transformers in outdoor or exposed locations require additional weatherproofing and more frequent testing.

Conclusion: Prioritize Proactive Detection to Safeguard Your Transformers

Oil contamination in transformer is not a question of “if” but “when”—but with the right detection methods, prevention protocols, and rapid response, you can avoid catastrophic failures and extend your equipment’s life. The key takeaways from this guide are clear:

- Combine multiple detection methods (visual, DGA, dielectric strength, etc.) for a comprehensive assessment of oil condition.

- Use a mix of on-site testing for routine monitoring and lab testing for in-depth analysis.

- Establish clear warning signs and response protocols to address contamination early.

- Invest in preventive maintenance and environmental control to reduce contamination risks.

Remember: The cost of prevention is always a fraction of the cost of failure. By implementing the strategies outlined in this guide, you can protect your transformers, minimize downtime, and avoid costly repairs. Whether you’re a maintenance technician, facility manager, or electrical engineer, the insights shared here—drawn from two decades of hands-on experience—will help you navigate the challenges of oil contamination and keep your transformers operating reliably.