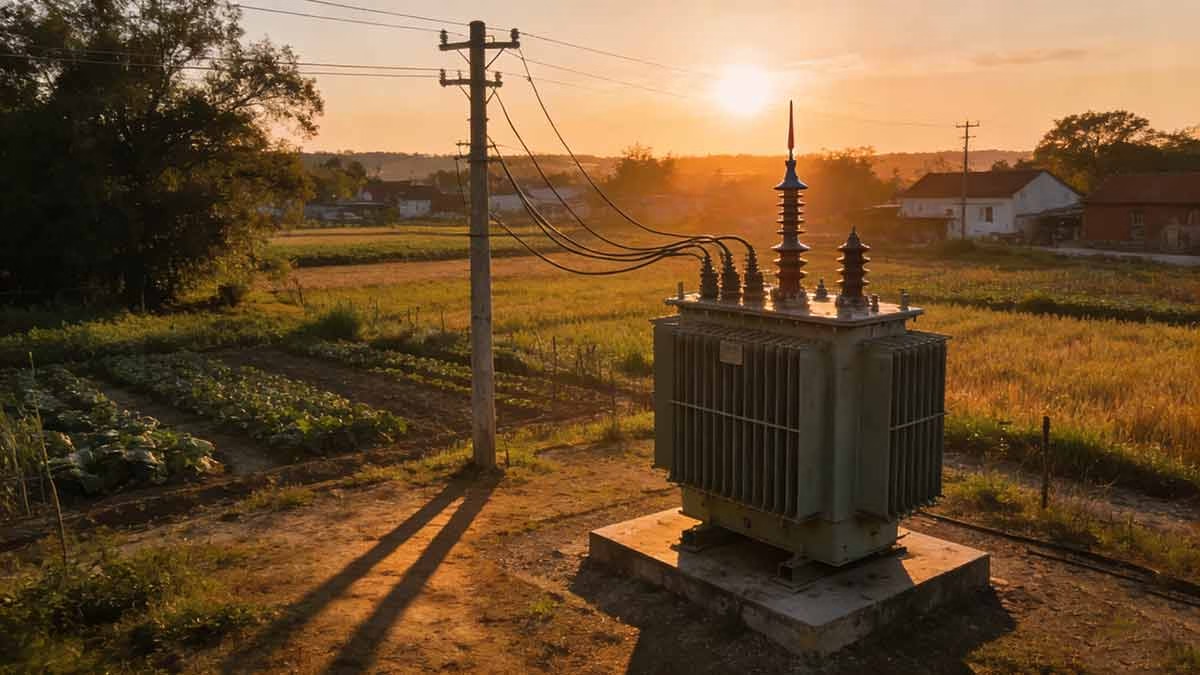

In the realm of power distribution and heavy-duty electrical operations, selecting the right transformer type directly impacts system reliability, operational costs, and service longevity. Among the two dominant transformer categories—oil immersed and dry-type—oil immersed transformers have stood the test of time as a preferred solution for high-power, continuous-load applications. While the fundamental merits of oil-filled units are widely recognized, a deep dive into their thermal management mechanisms, maintenance requirements, and safety protocols reveals why they remain a staple in electrical projects ranging from utility-scale power grids to heavy industrial facilities. This comprehensive guide dissects the core benefits of using oil immersed transformers, addressing critical user questions about performance, durability, and cost to help stakeholders make informed investment decisions.

Contents

hide

How Do Oil Immersed Transformers Boost Cooling Efficiency to Deliver Operational Benefits?

For anyone evaluating the benefits of using oil immersed transformers, understanding their superior thermal dissipation capability is the starting point of this analysis. Unlike dry-type units that rely on air for heat transfer, oil immersed transformers leverage specialized insulating oil to circulate around the core and windings, creating a highly efficient heat absorption and dissipation cycle that elevates overall operational stability, especially under high-load conditions.

The Science Behind Oil-Based Thermal Regulation

The insulating oil within these transformers serves a dual purpose: it acts as both a dielectric medium to prevent electrical arcing and a thermal conductor to draw heat away from critical components. As the transformer operates, electrical resistance in the windings generates heat, causing the surrounding oil to expand and rise due to natural convection. This heated oil flows toward the transformer’s radiator fins or external cooling assemblies, where it releases heat into the ambient air. Once cooled, the oil contracts and sinks back to the bottom of the unit, restarting the cycle without the need for external mechanical pumps.

This passive cooling mechanism is a game-changer for high-power applications. Unlike forced-air cooling systems used in many dry-type transformers— which require fans, blowers, and additional energy input to maintain thermal stability—oil immersed transformers rely on the natural properties of the oil to regulate temperature. This not only eliminates the energy consumption associated with auxiliary cooling equipment but also reduces the risk of mechanical failures caused by fan malfunctions or clogged air filters.

Heat Loss Mechanisms: Oil Immersed vs. Air-Cooled Systems

To quantify the benefits of using oil immersed transformers in terms of cooling efficiency, it is essential to compare their heat loss mechanisms against air-cooled dry-type alternatives. Oil has a significantly higher specific heat capacity than air, meaning it can absorb more heat per unit volume without a drastic temperature rise. This allows oil immersed transformers to maintain consistent operational temperatures even when subjected to peak loads that would cause dry-type units to overheat.

The following table highlights the core differences in thermal performance between the two transformer types:

| Thermal Regulation Feature | Oil Immersed Transformers | Dry-Type Transformers |

|---|---|---|

| Thermal Transfer Medium | Specialized insulating oil | Ambient air |

| High-Load Operational Stability | Exceptional (sustains peak loads for extended periods) | Moderate (requires auxiliary cooling for heavy loads) |

| Dependence on Auxiliary Cooling Equipment | Minimal (passive convection suffices for most scenarios) | High (fans/blowers mandatory for high-power use cases) |

| Energy Consumption for Cooling | Near-zero (passive system) | High (auxiliary equipment draws additional power) |

Natural Convection: The Key to Uninterrupted Cooling Performance

Natural convection is the unsung hero behind the cooling efficiency benefits of using oil immersed transformers. This process eliminates the need for external power sources to drive heat transfer, making the units highly reliable in remote or off-grid locations where access to auxiliary power is limited. Even in the event of a grid outage, the residual oil in the transformer can continue to dissipate heat, preventing overheating and component damage until power is restored.

Moreover, the uniform temperature distribution enabled by oil circulation prevents the formation of hotspots—localized areas of excessive heat that accelerate insulation degradation and shorten transformer lifespan. In dry-type transformers, air flow can be uneven, leading to hotspots in dense winding sections that often go undetected until they cause catastrophic failures. By contrast, oil immersed transformers maintain consistent temperatures across all components, mitigating this critical risk.

How Enhanced Cooling Translates to Operational Advantages

The superior cooling efficiency of oil immersed transformers directly translates to tangible operational benefits. Lower operating temperatures reduce thermal stress on the core, windings, and insulation materials, which in turn minimizes the risk of premature breakdowns and unplanned downtime. For industrial facilities and power utilities, this means higher system uptime, reduced maintenance interruptions, and the ability to handle fluctuating load demands without compromising performance. In high-power applications such as steel mills, chemical plants, and regional power grids, these benefits are not just advantageous—they are indispensable.

What Longevity Benefits Can Users Gain from Using Oil Immersed Transformers?

Beyond cooling efficiency, one of the most compelling benefits of using oil immersed transformers is their extended service lifespan, which can exceed 40 years with proper maintenance—far longer than the typical 20–25 year lifespan of dry-type units. This longevity stems from three core advantages: reduced thermal stress, robust insulation protection, and simplified maintenance protocols that preserve component integrity over time.

Reduced Thermal Stress: The Foundation of Long Service Life

As outlined in the previous section, the oil-based cooling system of oil immersed transformers maintains consistently low operating temperatures, drastically reducing thermal stress on internal components. Thermal stress is a primary driver of transformer aging; repeated cycles of heating and cooling cause insulation materials to expand and contract, leading to cracks, brittleness, and eventual failure. By minimizing these temperature fluctuations, oil immersed transformers slow down the aging process of critical parts, extending their usable life by decades.

Additionally, the uniform temperature distribution achieved through oil circulation eliminates hotspots, which are a major cause of insulation breakdown in dry-type transformers. Hotspots can reach temperatures that exceed the thermal rating of insulation materials, causing them to degrade rapidly and create short-circuit risks. Oil immersed transformers avoid this issue entirely, ensuring that all components operate within their optimal temperature range.

Robust Insulation Properties: Shielding Components from Electrical Damage

Another key benefit of using oil immersed transformers is the superior insulation protection provided by the dielectric oil. Unlike the solid insulation materials used in dry-type units—such as epoxy resin or cast resin—the insulating oil in oil immersed transformers forms a continuous, liquid barrier around the core and windings. This barrier not only prevents electrical arcing and short circuits but also resists degradation under high voltage and temperature conditions.

The dielectric strength of transformer oil is significantly higher than that of air, which is the primary insulation medium for dry-type units. This means oil immersed transformers can withstand higher voltage spikes and electrical surges without sustaining damage, making them ideal for use in regions with unstable power grids or high levels of electrical interference. Over time, the oil can be tested and reconditioned to maintain its dielectric strength, whereas solid insulation materials in dry-type transformers degrade irreversibly and require full replacement once damaged.

Maintenance Advantages That Extend Lifespan

While all transformers require periodic maintenance, the benefits of using oil immersed transformers become even more apparent when comparing their upkeep requirements to dry-type alternatives. Oil immersed units demand less frequent and less invasive maintenance, which not only reduces operational costs but also minimizes the risk of component damage during service procedures.

Routine maintenance for oil immersed transformers primarily involves:

- Oil quality testing: Analyzing dielectric strength, moisture content, and acidity levels to identify contamination or degradation. These tests can be performed without dismantling the transformer, using portable sampling kits.

- Seal inspection: Checking for oil leaks at flange connections and valve points, which can be repaired quickly with replacement gaskets.

- Radiator cleaning: Removing dust and debris from radiator fins to maintain heat dissipation efficiency.

In contrast, dry-type transformers require more frequent and complex maintenance, including:

- Insulation resistance testing: Measuring the integrity of solid insulation materials, which often requires disassembling parts of the unit.

- Fan and blower servicing: Cleaning filters, lubricating bearings, and replacing worn components to ensure auxiliary cooling systems function properly.

- Winding inspection: Checking for signs of overheating or insulation damage, which involves opening the transformer casing and exposing internal components to dust and moisture.

The table below summarizes the longevity and maintenance benefits of using oil immersed transformers versus dry-type units:

| Longevity & Maintenance Feature | Oil Immersed Transformers | Dry-Type Transformers |

|---|---|---|

| Thermal Stress Resistance | High (uniform temperature distribution eliminates hotspots) | Moderate (uneven air flow increases thermal stress) |

| Insulation Strength & Durability | Superior (liquid dielectric oil resists voltage surges) | Moderate (solid insulation degrades irreversibly over time) |

| Expected Service Lifespan | 35–45 years (with proper maintenance) | 20–25 years |

| Maintenance Frequency | Low (annual oil testing; bi-annual seal inspection) | High (quarterly fan servicing; annual insulation testing) |

| Invasiveness of Maintenance | Minimal (no need for disassembly) | High (requires partial disassembly for core inspections) |

How Do Oil Immersed Transformers Outperform Dry-Type Units in Core Application Scenarios?

To fully grasp the benefits of using oil immersed transformers, it is essential to compare their performance, safety profiles, and suitability for specific applications against dry-type transformers. While dry-type units have their own advantages—such as lower fire risk for indoor installations—oil immersed transformers excel in high-power, outdoor, and industrial scenarios where reliability and efficiency are paramount.

Performance and Efficiency: High-Power Applications as a Core Strength

The primary benefit of using oil immersed transformers in high-power applications is their ability to handle heavy loads without sacrificing efficiency. As noted earlier, oil’s superior thermal transfer properties allow these units to maintain high efficiency levels even under peak load conditions. Dry-type transformers, by contrast, experience a significant drop in efficiency when operating at or above 80% of their rated capacity, due to the limitations of air cooling.

For utility-scale power grids and heavy industrial facilities—such as mining operations, cement plants, and renewable energy farms—this efficiency gap translates to substantial energy savings over time. Oil immersed transformers also have lower no-load losses, meaning they consume less energy when operating at reduced loads, which is a critical advantage for facilities with fluctuating power demands.

Safety and Environmental Considerations: Balancing Risk and Responsibility

One common misconception about oil immersed transformers is that they pose a higher safety risk than dry-type units due to the flammability of transformer oil. While it is true that mineral oil-based transformers have a higher fire risk, modern oil immersed units use fire-resistant or biodegradable vegetable-based oils that mitigate this concern. Additionally, proper installation practices—such as using containment tanks to prevent oil spills—eliminate environmental risks associated with leaks.

Dry-type transformers do have a lower fire risk, making them ideal for indoor installations in densely populated areas, such as commercial buildings, hospitals, and schools. However, this safety advantage comes with trade-offs in performance and efficiency, which make dry-type units unsuitable for high-power outdoor applications. The table below compares the safety and environmental profiles of the two transformer types:

| Safety & Environmental Feature | Oil Immersed Transformers | Dry-Type Transformers |

|---|---|---|

| Cooling & Insulation Medium | Fire-resistant/mineral/vegetable oil | Air + solid insulation |

| Fire Risk | Moderate (mitigated by modern oil types and containment systems) | Low (no flammable components) |

| Environmental Impact | Minimal (containment tanks prevent spills; biodegradable oils available) | Low (no liquid waste generated) |

| Ideal Installation Location | Outdoor, industrial, utility-scale power grids | Indoor, commercial, low-power applications |

Application Suitability: Matching Transformer Type to Operational Needs

The benefits of using oil immersed transformers are most pronounced in scenarios where high power output, continuous operation, and long service life are non-negotiable. These applications include:

- Utility power distribution networks (stepping up/down voltage for regional grids)

- Heavy industrial facilities (steel mills, chemical plants, manufacturing plants)

- Renewable energy projects (solar farms, wind turbines, hydroelectric plants)

- Remote off-grid installations (mining camps, rural electrification projects)

Dry-type transformers, on the other hand, are better suited for low-power, indoor applications where fire safety is a top priority. Examples include office buildings, retail centers, and data centers with moderate power demands.

When selecting a transformer type, stakeholders must weigh the benefits of using oil immersed transformers against their specific operational needs. For projects that require high efficiency, extended lifespan, and the ability to handle heavy loads, oil immersed units are the clear choice.

What Cost-Effectiveness Advantages Come with Using Oil Immersed Transformers?

While the upfront cost of oil immersed transformers may be higher than that of dry-type units, the long-term cost-effectiveness benefits of using oil immersed transformers far outweigh the initial investment. A comprehensive cost analysis must include three key factors: upfront purchase and installation costs, ongoing maintenance and operational costs, and total lifecycle costs (including replacement expenses).

Upfront Costs: Balancing Initial Investment with Long-Term Value

Oil immersed transformers indeed have a higher upfront price tag than dry-type units, primarily due to the cost of the oil cooling system, radiator assemblies, and containment infrastructure. However, this higher initial investment is justified by the unit’s superior performance and longevity. For high-power applications, a single oil immersed transformer can replace multiple dry-type units, reducing the total number of transformers required and lowering overall installation costs.

Additionally, the installation process for oil immersed transformers is often simpler than for dry-type units, especially for outdoor applications. Dry-type units require specialized indoor enclosures and auxiliary cooling systems, which add to the upfront cost. Oil immersed transformers can be installed outdoors without the need for costly housing, further offsetting the initial price difference.

Operational and Maintenance Costs: Minimizing Long-Term Expenses

One of the most significant financial benefits of using oil immersed transformers is their low operational and maintenance costs. As previously discussed, these units rely on passive cooling, eliminating the energy consumption associated with fan and blower systems in dry-type transformers. Over a 40-year lifespan, this energy savings can amount to thousands of dollars, depending on the unit’s size and operating hours.

Maintenance costs are also substantially lower for oil immersed transformers. Routine oil testing and seal inspections are far less expensive than the frequent fan servicing and insulation testing required for dry-type units. Additionally, the minimal invasiveness of oil immersed transformer maintenance means less downtime during service procedures, reducing lost productivity for industrial facilities.

Total Lifecycle Cost Analysis: The Ultimate Cost-Effectiveness Metric

When evaluating the benefits of using oil immersed transformers, total lifecycle cost (TLC) is the most critical metric. TLC accounts for all costs associated with the transformer from purchase to disposal, including upfront costs, operational costs, maintenance costs, and replacement costs.

For example, a 10 MVA oil immersed transformer with a 40-year lifespan may have an upfront cost of $150,000, annual operational and maintenance costs of $2,000, and a total lifecycle cost of $230,000. A comparable dry-type transformer with a 25-year lifespan may have an upfront cost of $100,000, annual operational and maintenance costs of $5,000, and a total lifecycle cost of $225,000 over 25 years. To match the 40-year lifespan of the oil immersed unit, two dry-type transformers would be required, bringing the total lifecycle cost to $450,000—nearly double the cost of the oil immersed unit.

The table below summarizes the cost comparison between oil immersed and dry-type transformers for a high-power industrial application:

| Cost Category | Oil Immersed Transformer (40-Year Lifespan) | Dry-Type Transformer (25-Year Lifespan) | Two Dry-Type Transformers (40-Year Equivalent) |

|---|---|---|---|

| Upfront Purchase & Installation Cost | $150,000 | $100,000 | $200,000 |

| Annual Operational & Maintenance Cost | $2,000 | $5,000 | $5,000 |

| Total Lifecycle Cost | $230,000 | $225,000 | $450,000 |

Environmental Compliance Costs: Mitigating Risks with Proactive Measures

While oil immersed transformers require compliance with environmental regulations related to oil spills and disposal, these costs are minimal when proper containment systems are installed. Modern oil immersed transformers use biodegradable vegetable oils that reduce environmental risk and simplify disposal, further lowering compliance costs. Dry-type transformers have their own environmental costs, such as the disposal of solid insulation materials that cannot be recycled, which are often overlooked in initial cost analyses.

Conclusion

The benefits of using oil immersed transformers span every critical dimension of electrical system performance: superior cooling efficiency that enables high-power operation, extended service lifespan that reduces replacement frequency, application versatility that suits industrial and utility-scale projects, and long-term cost-effectiveness that delivers substantial financial savings over time. While dry-type transformers are the right choice for low-power, indoor applications, oil immersed transformers are the gold standard for projects where reliability, efficiency, and durability are paramount.

By understanding the science behind oil-based cooling, the insulation advantages that protect critical components, and the total lifecycle cost benefits that drive long-term value, stakeholders can make informed decisions that align with their operational needs and financial goals. For industrial facilities, power utilities, and renewable energy projects, investing in oil immersed transformers is not just a purchase—it is a strategic investment in the long-term stability and profitability of their electrical systems.

Final Note

All data and insights presented in this guide are based on industry-standard engineering practices and real-world operational data. For specific application recommendations or custom transformer solutions, consult a qualified electrical engineering professional to ensure optimal performance and compliance with local regulations.