How Three Phase Pad Mounted Transformers Work: Core Mechanics Unveiled

Key Components & Their Critical Functions

- Core: Constructed from 0.35–0.5mm laminated silicon steel (chosen for its low magnetic hysteresis loss), the core provides a concentrated pathway for magnetic flux. Its three-legged or five-legged design ensures balanced energy transfer across all three phases.

- Windings: Primary windings (connected to high-voltage lines) and secondary windings (delivering low-voltage output) are typically made of high-conductivity copper (or aluminum for cost-sensitive applications), wound in a way that minimizes resistance and heat generation.

- Insulation System: An oil-filled tank (using mineral oil or biodegradable ester oil) serves dual purposes: cooling the windings and providing electrical insulation. Paper insulation (impregnated with oil) wraps the windings to prevent arcing and short circuits, meeting IEC 60422 insulation class requirements.

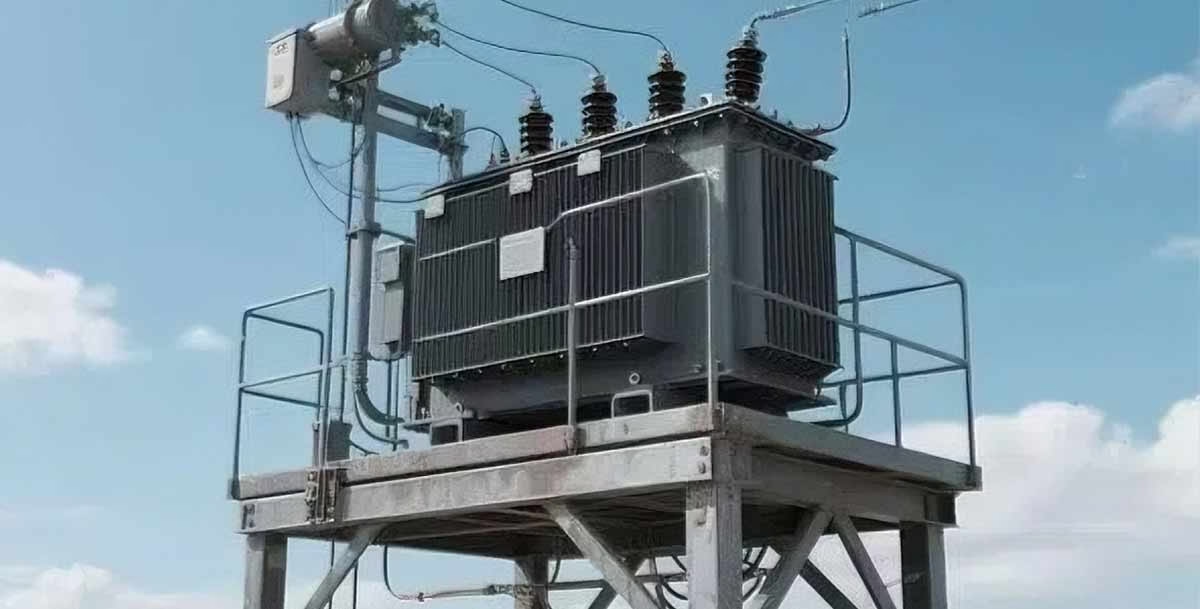

- Bushings: Porcelain or polymer bushings act as insulated connectors, linking internal windings to external power lines. High-voltage bushings (on the primary side) are designed to withstand voltage surges, while low-voltage bushings prioritize current-carrying capacity.

- Tap Changer: A mechanical or electronic component that adjusts the number of winding turns, allowing voltage regulation (±5% or ±10% of nominal voltage) to compensate for grid fluctuations and maintain consistent output.

Real-World Applications: Where Three Phase Pad Mounted Transformers Shine

Residential Communities

Commercial & Mixed-Use Developments

Industrial Parks & Manufacturing Facilities

Institutional & Critical Infrastructure

Renewable Energy Integration

Three Phase vs. Single Phase Pad Mounted Transformers: Which Is Right for Your Project?

Power Capacity & Efficiency

- Three Phase: Designed for high loads, with ratings ranging from 75 kVA to 5000 kVA. According to IEEE 1159 standards, they achieve 98–99% efficiency for large loads, thanks to balanced current flow that minimizes copper loss and heat generation.

- Single Phase: Limited to smaller loads (up to 167 kVA), with efficiency ratings of 97–98%. They’re more prone to energy loss when powering high-demand equipment.

Voltage Stability

- Three Phase: Delivers consistent voltage even with fluctuating loads, making them ideal for sensitive equipment (e.g., industrial machinery, data center servers) that requires stable power.

- Single Phase: Voltage fluctuations are more common, especially in areas with varying residential demand (e.g., peak hours for air conditioning).

Application Suitability

- Three Phase: Best for commercial, industrial, and large residential projects (50+ units), as well as renewable energy and smart grid applications.

- Single Phase: Cost-effective for small residential developments (fewer than 50 units), rural areas with low power demand, or standalone structures (e.g., small offices, garages).

Cost Considerations

- Three Phase: Higher initial cost (20–40% more than single phase), but lower long-term expenses due to reduced infrastructure needs (fewer transformers required for large loads) and lower energy loss.

- Single Phase: Lower upfront cost, but less cost-effective for high-demand applications—requiring multiple units to match the capacity of a single three phase transformer.

Optimizing Performance: Selection & Maintenance Best Practices

Key Selection Criteria

- Load Assessment: Calculate current and future power needs (accounting for 10–20% growth) to choose the right kVA rating. Over-sizing leads to unnecessary energy loss; under-sizing causes overheating and premature failure.

- Voltage Compatibility: Match primary (high-voltage) and secondary (low-voltage) ratings to your grid and end-user requirements. Ensure the tap changer range (e.g., ±5%) aligns with local voltage fluctuations.

- Environmental Factors: For harsh conditions (coastal areas, deserts, industrial zones), select transformers with corrosion-resistant enclosures (e.g., hot-dipped galvanized steel), sealed tanks to prevent moisture ingress, and temperature-rated windings (up to 115°C).

- Safety & Compliance: Verify compliance with local standards (e.g., NEC, IEC, ANSI) for grounding, fault current handling, and fire safety. Look for units with pressure relief valves and fault detection systems.

Proactive Maintenance Guidelines

- Oil Testing: Conduct annual dissolved gas analysis (DGA) and moisture testing (per IEC 60422) to detect insulation degradation, arcing, or overheating. Replace oil if moisture content exceeds 30 ppm or acidity levels rise above 0.1 mg KOH/g.

- Thermal Imaging: Perform semi-annual thermal scans (using infrared cameras) to identify hot spots in windings, bushings, or connections—early indicators of loose terminals or internal faults.

- Load Monitoring: Use smart meters to track load levels monthly. Avoid operating transformers above 80% of their rated capacity for extended periods to prevent overheating.

- Bushing Inspection: Check bushings quarterly for cracks, leaks, or contamination. Clean with dielectric fluid if needed to maintain insulation integrity.

- Acoustic Emission Testing: Conduct bi-annual AE testing to detect partial discharges (tiny electrical arcs) inside the tank—an early warning sign of insulation failure that’s undetectable by visual or thermal inspections.

Smart Grid Integration: Challenges & Innovations Shaping the Future

Key Opportunities in Smart Grid Integration

- Real-Time Monitoring: Equipping transformers with IoT sensors (for temperature, load, oil quality, and vibration) enables utility providers to monitor performance remotely. This data supports predictive maintenance, reducing unplanned outages by 40% (per a 2023 IEEE study).

- Automated Voltage Regulation: Smart tap changers (controlled by AI algorithms) adjust voltage in real time, compensating for fluctuations from EV charging, solar/wind generation, and peak demand. This improves voltage stability by 15% and reduces energy loss.

- Bidirectional Power Flow: Modern three phase transformers support two-way power flow, critical for integrating distributed energy resources (DERs) like rooftop solar panels and residential battery storage. This allows excess energy from homes to feed back into the grid, reducing reliance on fossil fuels.

- EV Charging Support: High-capacity three phase transformers (2000+ kVA) power fast-charging stations (50kW+), addressing the growing demand for electric vehicle infrastructure. Smart load management ensures EV charging doesn’t overload the grid during peak hours.

Critical Challenges to Address

- Cybersecurity: Connecting transformers to digital networks increases vulnerability to cyberattacks. Utilities must implement end-to-end encryption, secure communication protocols (e.g., IEC 62351), and regular penetration testing to protect critical infrastructure.

- Cost of Smart Components: IoT sensors, AI controllers, and smart tap changers add 15–25% to the initial cost of transformers. However, the long-term savings from reduced maintenance and improved efficiency often offset this investment within 3–5 years.

- Interoperability: Ensuring smart transformers work seamlessly with existing grid management systems requires adherence to open standards (e.g., OpenADR, DNP3). This avoids vendor lock-in and enables scalable integration.

Conclusion

More FAQ About Three Phase Pad Mounted Transformer

Q: What is a three-phase pad-mounted transformer?

A: A three-phase pad-mounted transformer is a ground-mounted distribution transformer designed to handle three-phase alternating current power. It is enclosed in a tamper-resistant metal cabinet and installed on a concrete pad, making it suitable for outdoor use in public areas, commercial districts, and industrial zones. Unlike pole-mounted transformers, it operates at ground level and is widely used to step down high-voltage electricity from transmission lines to lower voltages suitable for residential, commercial, and industrial applications.

Q: What are the typical applications of three-phase pad-mounted transformers?

A: They have versatile applications including public infrastructure (powering public lighting and traffic signals), commercial buildings (office buildings, shopping malls, business centers), industrial facilities (heavy machinery plants, industrial parks), data centers (supporting sensitive IT infrastructure),high-density residential communities, renewable energy systems (solar and wind power distribution) and emerging fields like EV charging stations and battery energy storage systems (BESS).

Q: What are the key features of three-phase pad-mounted transformers?

A: Key features include a compact design that fits narrow spaces,tamper-resistant and weatherproof metal enclosures for outdoor safety, stable three-phase power output with balanced load capacity, low maintenance requirements, and long service life. Most models adopt fully sealed and insulated designs, equipped with accessories like temperature gauges, pressure release valves, and tap changers. They also comply with international standards to ensure reliable operation in various environments.

Q: How to select the right kVA rating for a three-phase pad-mounted transformer?

A: The kVA rating selection depends on the total power demand of connected loads. First, calculate the sum of active power (kW) of all equipment, then divide by the expected power factor (usually 0.8-0.9 for industrial and commercial applications) to get the required apparent power (kVA) . Typical ratings range from 45 kVA to 12,000 kVA.For example,225 kVA models are suitable for small commercial buildings, while 1500-3000 kVA models are used in industrial parks and large-scale renewable energy projects. It’s also necessary to consider future load expansion and overload capacity.

Q: What are the common faults of three-phase pad-mounted transformers, and how to solved?

A: Common faults include oil leakage, overheating, bushing failures, and internal short circuits. Oil leakage can be solved by replacing damaged seals and tightening bolts. Overheating may be caused by overload or poor heat dissipation, requiring load reduction and cleaning of cooling systems. Bushing failures need immediate replacement to avoid discharge hazards. Internal faults detected by DGA or abnormal noise require professional maintenance or winding repair. All fault handling should be performed by qualified personnel following safety guidelines to prevent injury or further damage.

Q: How to ensure the safety of three-phase pad-mounted transformers during operation?

A: Safety measures include tamper-resistant locked enclosures to prevent unauthorized access, reliable grounding systems for the tank, core, and neutral point, installation of overcurrent and short-circuit protection devices, and pressure release valves for oil-immersed models. Operators must wear insulating protective equipment and follow lockout/tagout procedures during maintenance. Safety signs should be posted around the installation site to warn pedestrians and prevent accidental contact. Compliance with ANSI and IEC safety standards is fundamental to ensuring operational safety.

Q: How to choose between three-phase pad-mounted and pole-mounted transformers?

A: The choice depends on installation space, power demand, and environment. Three-phase pad-mounted transformers are suitable for areas with underground power lines, limited overhead space, or high power demand (industrial, commercial,high-density residential). They offer higher capacity and better protection but require a concrete pad. Pole-mounted transformers are used for low to medium-capacity applications in rural or suburban areas with overhead power lines. They save ground space but have lower capacity and are more exposed to weather conditions . Three-phase pad-mounted models are preferred for three-phase power supply, while pole-mounted models are often single-phase.