When it comes to selecting a transformer for your residential, commercial, or industrial needs, one of the most critical decisions you’ll face is choosing between a single phase vs three phase transformer. Many customers find themselves confused by technical jargon, unclear about which type matches their power requirements, or unsure about long-term efficiency and cost implications. This article aims to resolve these doubts with authoritative explanations, detailed comparisons, and practical guidance—all based on international standards and industry best practices. By the end, you’ll have a clear understanding of how these two transformer types differ, their ideal applications, and how to make an informed choice that aligns with your specific needs.

First, let’s establish a foundational understanding of transformers and their core function. A transformer is an electrical device that transfers electrical energy between two or more circuits through electromagnetic induction, adjusting voltage levels (stepping up or stepping down) without changing the frequency of the alternating current (AC). The key distinction between single phase and three phase transformers lies in the type of AC power they handle and the structural design that enables this functionality. This difference directly impacts their power capacity, efficiency, application scope, and cost—factors that are central to your decision-making process.

Contents

hide

What Are Single Phase and Three Phase Transformers? Core Definitions

Before diving into comparisons, it’s essential to clarify the basic definitions of each transformer type. Understanding their fundamental nature will help you grasp the subsequent technical differences and application nuances.

Single Phase Transformer: Simplified Power for Low-Demand Scenarios

A single phase transformer is designed to operate with single phase alternating current, which consists of a single voltage waveform oscillating at a specific frequency (e.g., 50Hz or 60Hz, depending on the region). Its core structure comprises two windings—primary (connected to the input power source) and secondary (connected to the load)—wound around a magnetic core made of laminated silicon steel sheets. This laminated core minimizes energy loss due to eddy currents, a critical factor for efficiency in low-power applications.

The working principle follows Faraday’s law of electromagnetic induction: when alternating current flows through the primary winding, it creates a varying magnetic flux in the core. This flux induces an electromotive force (EMF) in the secondary winding, with the voltage ratio determined by the turns ratio of the two windings (V₁/V₂ = N₁/N₂, where V is voltage and N is the number of turns). Single phase transformers are typically available in small to medium capacities, ranging from a few volt-amperes (VA) to around 500 kilovolt-amperes (kVA).

Three Phase Transformer: High-Capacity Power for Industrial Demands

A three phase transformer processes three phase alternating current, which consists of three separate voltage waveforms (phases) that are 120 degrees out of phase with each other. This configuration allows for more efficient power generation, transmission, and distribution, making it the standard for industrial and large-scale commercial applications. Structurally, it features three sets of primary and secondary windings, each wound around a three-limb magnetic core (three-column core design).

Similar to single phase transformers, electromagnetic induction drives its operation, but with the added benefit of balanced power transfer. The three windings can be connected in two primary configurations: star (Y) or delta (Δ), each offering distinct voltage and current characteristics. For example, a Y/Δ connection (star on the high-voltage side, delta on the low-voltage side) is common in distribution transformers due to its ability to handle unbalanced loads and provide neutral points for single phase loads. Three phase transformers typically have capacities starting from 100 kVA and can reach several megavolt-amperes (MVA), making them suitable for heavy-duty industrial equipment and power grid applications.

Single Phase vs Three Phase Transformer: Key Differences at a Glance

To help you quickly compare the two transformer types, we’ve compiled a comprehensive table highlighting their core differences in structure, performance, application, and cost. This visual summary distills complex technical details into easily digestible insights.

Characteristics | Single Phase Transformer | Three Phase Transformer |

|---|---|---|

Input/Output Phase | Single phase (2 wires: hot + neutral) | Three phases (3 wires: L1, L2, L3; optional neutral for Y-connection) |

Core Structure | Single-limb or shell-type (rectangular or “mouth” shape) laminated silicon steel core | Three-limb laminated silicon steel core (integrated design) |

Winding Configuration | 2 windings (primary + secondary); simple connection | 6 windings (3 primary + 3 secondary); configurable as Y/Y, Y/Δ, Δ/Y, Δ/Δ |

Power Capacity Range | Low to medium: a few VA to 500 kVA | Medium to high: 100 kVA to several MVA |

Efficiency | Lower at high loads; efficient for small, steady loads | Higher at high loads; 10-15% more efficient than three single phase transformers in parallel |

Cost (Initial + Operational) | Lower initial cost; higher operational cost for large loads (due to lower efficiency) | Higher initial cost; lower long-term operational cost for large loads (energy savings offset initial investment) |

Size & Weight | Smaller and lighter; easy to install in confined spaces | Larger and heavier; requires more installation space and structural support |

Load Balance | Cannot balance loads; relies on a single phase supply | Naturally balances three phase loads; can handle minor unbalances without efficiency loss |

Maintenance Requirements | Simple; fewer components mean lower maintenance needs and costs | More complex, requires regular inspection of winding connections and core; higher maintenance costs |

Application Scope | Residential buildings, small commercial spaces (offices, shops), household appliances, and small electronic devices | Industrial facilities, large commercial buildings (malls, data centers), power grids, heavy machinery (motors, compressors) |

Compliance Standards | IEC 60076-1:2011, GB 1094.1-2013 (for capacities ≥1 kVA) | IEC 60076-1:2011, GB 1094.1-2013 (for capacities ≥5 kVA) |

Core Construction and Winding Configurations: Why They Matter

The structural differences between single phase and three phase transformers are not just technical details—they directly impact performance, reliability, and suitability for specific applications. Let’s explore these differences in depth to understand how they influence your choice.

Single Phase Transformer Construction

The core of a single phase transformer is typically made of thin silicon steel laminations stacked together to reduce eddy current losses. The two most common core designs are:

- Core-type: The windings are wrapped around two vertical limbs of the core, with horizontal yokes connecting the limbs. This design is compact and cost-effective, making it ideal for small to medium capacity transformers (up to 200 kVA) used in residential and small commercial applications.

- Shell-type: The core surrounds the windings, forming a “mouth” shape. This design provides better magnetic flux linkage and higher mechanical strength, making it suitable for transformers with higher voltage ratings or where space is limited (e.g., in electronic devices).

The windings (primary and secondary) are made of copper or aluminum conductors, with insulation materials (such as paper or polymer) separating the turns to prevent short circuits. The simplicity of this design means single phase transformers are easy to manufacture, install, and repair—key advantages for low-demand scenarios.

Three Phase Transformer Construction

Three phase transformers feature a three-limb core, with each limb supporting a pair of primary and secondary windings (one for each phase). The core laminations are arranged to ensure balanced magnetic flux across all three phases, which is critical for efficient power transfer.

The winding connections (Y or Δ) are a defining feature of three phase transformers, as they determine the voltage output and load-handling capabilities:

- Star (Y) Connection: The ends of the three windings are connected to a common neutral point. This configuration provides a neutral wire for single phase loads (e.g., lighting in an industrial facility) and offers a higher voltage ratio (line voltage = √3 × phase voltage). It’s commonly used in high-voltage transmission and distribution transformers.

- Delta (Δ) Connection: The windings are connected in a closed loop, with no neutral point. This configuration is more robust for unbalanced loads and offers a lower voltage ratio (line voltage = phase voltage). It’s often used in low-voltage industrial applications where three phase motors are the primary load.

Compared to using three separate single phase transformers to power a three phase system, an integrated three phase transformer is more compact, uses 10-15% less material, and has higher efficiency—making it a more cost-effective solution for large-scale applications.

Efficiency and Energy Consumption: A Critical Comparison

Efficiency is a top priority for most customers, as it directly impacts long-term energy costs. Transformer efficiency is defined as the ratio of output power to input power, with losses occurring in the core (iron losses) and windings (copper losses).

Single Phase Transformer Efficiency

Single phase transformers are efficient for small, steady loads (e.g., household appliances), where their iron losses (hysteresis and eddy current losses) are minimal relative to the load. However, at high loads (above 70% of their rated capacity), their efficiency drops significantly. This is because copper losses (which increase with the square of the current) become dominant, and the simple core design cannot handle high magnetic flux densities as efficiently as a three phase core.

For example, a 5 kVA single phase transformer might have an efficiency of 95% at 50% load but drop to 90% at 100% load. This makes single phase transformers impractical for large, continuous loads, as the increased energy loss would lead to higher operational costs over time.

Three Phase Transformer Efficiency

Three phase transformers are designed for high efficiency at full load, making them ideal for industrial applications where loads are continuous and large. Their integrated core design reduces magnetic flux leakage, minimizing iron losses, while the balanced three-phase current distribution reduces copper losses compared to three single phase transformers in parallel.

A typical 100 kVA three phase transformer has an efficiency of 97-98% at full load, and it maintains high efficiency even at partial loads (above 30% of rated capacity). This efficiency advantage translates to significant energy savings over the transformer’s lifespan. For example, a 100 kVA three phase transformer operating at full load 24/7 will save approximately 10,000 kWh of electricity per year compared to three equivalent single phase transformers—resulting in cost savings of $1,000-$2,000 annually (depending on electricity rates).

Efficiency Comparison Chart

The following chart illustrates the efficiency of a 50 kVA single phase transformer and a 50 kVA three phase transformer across different load levels, highlighting the significant efficiency gap at higher loads.

Application Guidelines: Which Transformer Should You Choose?

The choice between single phase and three phase transformers ultimately depends on your power requirements, application type, and long-term cost goals. Below are practical guidelines to help you make the right decision.

Choose Single Phase Transformers If:

- You have a residential or small commercial application: Single phase transformers are the standard for homes, apartments, small offices, and shops. They power household appliances (refrigerators, microwaves, air conditioners), lighting systems, and small electronic devices—all of which run on single phase power.

- Your power demand is low (≤50 kVA): If your total load is less than 50 kVA, a single phase transformer is more cost-effective. For example, a small office with 10 computers, 5 printers, and lighting systems typically requires a 5-10 kVA single phase transformer.

- Space is limited: Single phase transformers are small and lightweight, making them easy to install in confined spaces (e.g., utility closets, basements).

- You need simple maintenance: With fewer components, single phase transformers require minimal maintenance—usually just regular inspection of connections and insulation.

Choose Three Phase Transformers If:

- You have an industrial or large commercial application: Three phase transformers are essential for factories, warehouses, data centers, shopping malls, and other large facilities. They power heavy machinery (three phase motors, compressors, pumps), industrial heating systems, and large-scale lighting arrays.

- Your power demand is high (>50 kVA): For loads exceeding 50 kVA, three phase transformers offer higher efficiency and lower long-term costs. For example, a manufacturing plant with multiple 10 hp motors will require a 100+ kVA three phase transformer.

- You need balanced power distribution: Three phase systems provide balanced power, which reduces voltage fluctuations and extends the lifespan of equipment. This is critical for industrial machinery that requires stable power to operate reliably.

- You want to reduce energy costs: While the initial cost is higher, the energy savings from a three phase transformer’s higher efficiency will offset the investment within 2-5 years for most industrial applications.

Cost Analysis: Single Phase vs Three Phase Transformers

Cost is a key consideration for any investment, and transformers are no exception. When evaluating cost, it’s important to consider both initial purchase price and long-term operational costs (energy and maintenance).

Initial Cost

Single phase transformers have a lower initial cost than three phase transformers of the same capacity. For example:

- A 10 kVA single phase transformer costs approximately $500-$800.

- A 10 kVA three phase transformer costs approximately $800-$1,200.

The price gap widens with increasing capacity. A 100 kVA single phase transformer (which is less common and often custom-built) can cost $5,000-$8,000, while a 100 kVA three phase transformer typically costs $3,000-$5,000. This is because three phase transformers are mass-produced for industrial use, leading to economies of scale.

Operational Costs

Operational costs include energy losses and maintenance expenses:

- Energy Losses: As discussed earlier, three phase transformers have lower energy losses at high loads. For a 100 kVA transformer operating 24/7 at full load, the annual energy cost for a single phase transformer (90% efficiency) is approximately $10,000 (based on $0.15/kWh), while the cost for a three phase transformer (97.5% efficiency) is approximately $3,000—a savings of $7,000 per year.

- Maintenance Costs: Single phase transformers have lower maintenance costs ($100-$200 per year) due to their simple design. Three phase transformers require more frequent inspections and maintenance, with annual costs ranging from $500-$1,000. However, this higher maintenance cost is offset by the energy savings for most large-scale applications.

Total Cost of Ownership (TCO) Over 10 Years

Calculating the TCO (initial cost + operational costs) over a 10-year lifespan highlights the long-term advantage of three phase transformers for high loads:

- 100 kVA Single Phase Transformer: $5,000 (initial) + $100,000 (energy) + $2,000 (maintenance) = $107,000

- 100 kVA Three Phase Transformer: $4,000 (initial) + $30,000 (energy) + $10,000 (maintenance) = $44,000

For low loads (≤50 kVA), the TCO of a single phase transformer is lower. For example, a 10 kVA single phase transformer has a 10-year TCO of approximately $15,000, compared to $20,000 for a three-phase transformer.

How to Identify Single Phase vs Three Phase Transformers

If you’re replacing an existing transformer or evaluating equipment in a facility, you may need to identify whether a transformer is single phase or three phase. Here are four simple methods to do so:

1. Check Input/Output Lines

Single phase transformers have two input lines (one hot, one neutral) and two output lines. Three phase transformers have three input lines (labeled L1, L2, L3) and three output lines. Some three phase transformers may also have a neutral line for Y-connections, but the presence of three hot lines is a clear indicator of three phase.

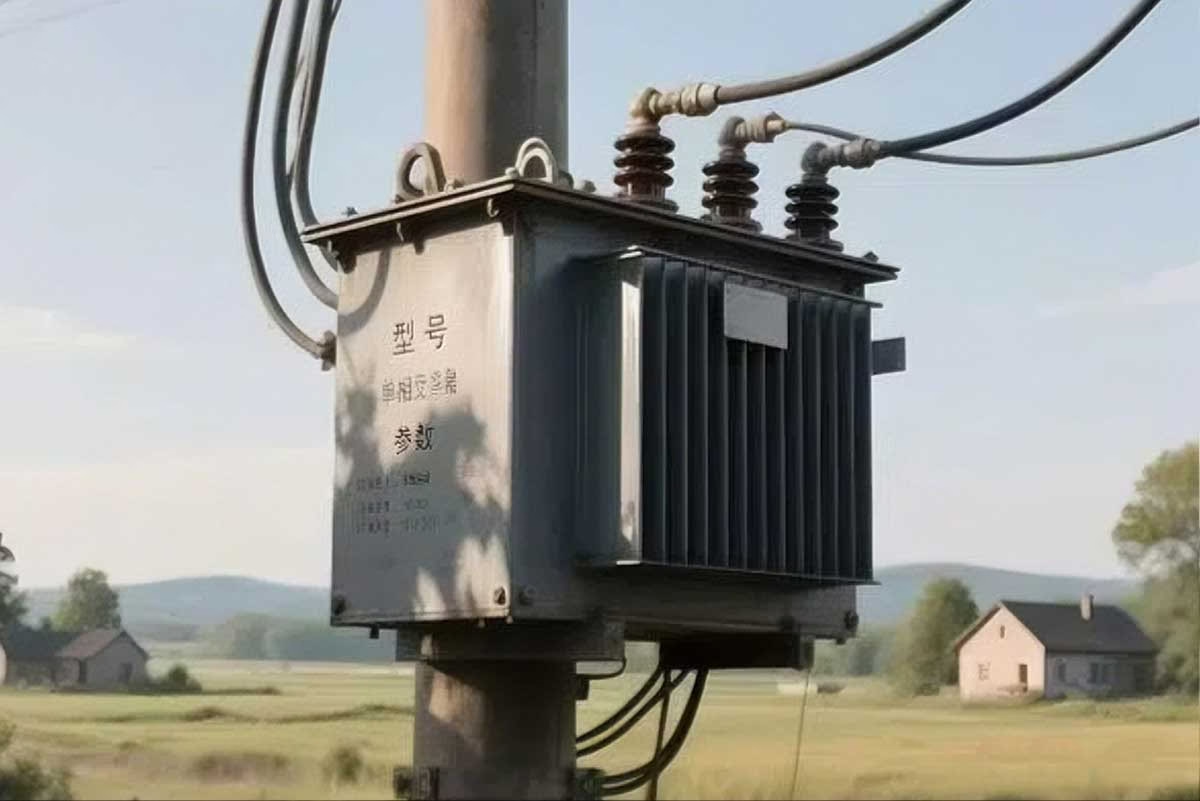

2. Examine the Nameplate

The nameplate (located on the transformer’s housing) provides critical information, including phase designation. Look for terms like “1 Ph” (single phase) or “3 Ph” (three phase). The nameplate will also list voltage ratings—single phase transformers typically have a single voltage rating (e.g., 240V), while three phase transformers may list multiple ratings (e.g., 208V/120V for Y-connected transformers).

3. Assess Physical Size and Weight

Single phase transformers are significantly smaller and lighter than three phase transformers of the same capacity. For example, a 10 kVA single phase transformer weighs 20-30 pounds, while a 10 kVA three phase transformer weighs 50-70 pounds. Three phase transformers also have a more robust housing to accommodate the larger core and windings.

4. Inspect Winding Terminals

Single phase transformers have two sets of terminals (primary and secondary), each with two connections. Three phase transformers have six sets of terminals (three primary, three secondary) or three sets of dual terminals for delta connections. The presence of six terminals is a strong indicator of a three phase transformer.

Compliance with International Standards: Ensuring Safety and Reliability

When selecting a transformer, it’s critical to choose a product that complies with international standards to ensure safety, reliability, and performance. The most relevant standards for single phase and three phase transformers are:

IEC 60076-1:2011

This international standard specifies fundamental technical requirements, design principles, and testing methodologies for power transformers, including both single phase and three phase types. It covers service conditions (normal and extreme environments), rated parameters (voltage, frequency, kVA), temperature rise limits, winding connections, and safety considerations. Compliance with IEC 60076-1:2011 ensures that the transformer can operate safely and reliably in global applications.

GB 1094.1-2013

This Chinese national standard (modified from IEC 60076-1:2011) applies to power transformers sold and used in China. It includes additional requirements for harmonic content, transportation, and environmental protection. For customers in China or supplying to Chinese markets, compliance with GB 1094.1-2013 is mandatory.

When purchasing a transformer, always ask the manufacturer for a certificate of compliance with these standards. This ensures that the product has undergone rigorous testing and meets the highest quality and safety requirements.

Conclusion: Making the Right Choice for Your Needs

The decision between single phase and three phase transformers boils down to your power requirements, application type, and long-term cost goals. Single phase transformers are the ideal choice for residential and small commercial applications with low power demands, offering simplicity, low initial cost, and easy installation. Three phase transformers, on the other hand, are the best option for industrial and large commercial applications with high, continuous loads, providing higher efficiency, balanced power distribution, and lower long-term operational costs.

By understanding the key differences outlined in this article—from structure and efficiency to cost and applications—you can make an informed decision that aligns with your specific needs. Always prioritize compliance with international standards (IEC 60076-1:2011, GB 1094.1-2013) to ensure safety and reliability, and consult with a trusted transformer manufacturer if you need personalized guidance on kVA rating, winding connections, or installation.

FAQ About Single Phase vs Three Phase Transformers

What is the core difference between a single phase and three phase transformer?

A single phase transformer operates with two conductors (line and neutral) and uses a single alternating current (AC) waveform, designed for low-power applications. In contrast, a three phase transformer utilizes three separate AC waveforms that are 120 degrees out of phase, transmitted through three conductors. The key distinction lies in power capacity, efficiency, and application scope: single phase units handle smaller loads, while three phase models deliver higher power with reduced energy loss, making them ideal for industrial and large-scale electrical systems. Both comply with IEC standards, but their core winding configurations and phase shift mechanisms differ fundamentally.

Which transformer is better for residential use in Africa?

For African residential areas, single phase transformers are the preferred choice. Most households in Africa have low-power requirements (e.g., lighting, small appliances, televisions) that range from 1kVA to 10kVA—exactly the capacity single phase units are designed for. They are more cost-effective, easier to install in compact spaces, and align with the single phase power supply commonly available in rural and suburban residential grids. Additionally, their simpler maintenance needs make them suitable for areas with limited technical expertise, a key consideration for many African communities.

When should I choose a three phase transformer for industrial applications in Africa?

Three phase transformers are indispensable for African industrial settings such as manufacturing plants, mines, data centers, and large-scale agricultural facilities. Industries in Africa typically require high-power equipment (e.g., motors, pumps, conveyor belts, heavy machinery) that demands 10kVA and above. Three phase units deliver consistent power with minimal voltage fluctuations, reducing equipment downtime—a critical factor for maximizing productivity. They also offer superior efficiency (often 95-98% compared to 85-92% for single phase models) when handling large loads, which lowers long-term energy costs, a major advantage for African businesses aiming to optimize operational expenses.

How do power capacity and load handling differ between single phase and three phase transformers?

Single phase transformers are limited to lower power capacities, generally ranging from 500VA to 50kVA, as they rely on a single waveform to transmit power. This makes them suitable for light loads like residential buildings, small shops, and street lighting. Three phase transformers, by contrast, can handle capacities from 10kVA up to several MVA (megavolt-amperes) due to their three-phase design, which distributes power more evenly across conductors. For example, a 100kVA three phase transformer can efficiently power an African textile factory or a medium-sized water treatment plant, while a single phase unit of the same capacity would be impractical due to size, weight, and energy inefficiency.

Are three phase transformers more energy-efficient than single phase models?

Yes, three phase transformers are inherently more energy-efficient, especially at medium to high loads. Their design reduces copper losses (I²R losses) and iron losses (hysteresis and eddy current losses) because the three alternating currents cancel out each other’s magnetic fields to some extent, minimizing wasted energy. In African markets, where energy conservation and cost reduction are priorities, this efficiency gap is significant: a 50kVA three phase transformer consumes 10-15% less energy than a single phase unit of the same capacity over a year. This efficiency also translates to lower carbon emissions, aligning with Africa’s growing focus on sustainable energy solutions.

What are the installation costs and complexity differences?

Single phase transformers have lower installation costs and simpler setup requirements. They require fewer conductors (two vs. three for three phase) and smaller mounting hardware, making them ideal for remote African areas with limited infrastructure. Installation can often be completed by local electricians with basic training. Three phase transformers, however, have higher installation costs due to the need for three-conductor wiring, specialized mounting, and professional calibration to ensure phase alignment. They also require skilled technicians familiar with three-phase power systems, which may be less accessible in rural African regions—though essential for industrial and urban projects.

Which transformer is more suitable for rural electrification projects in Africa?

Single phase transformers are the backbone of rural electrification in Africa. Projects like the African Development Bank’s Rural Electrification Program prioritize single phase units because they are affordable, portable, and can be deployed in small clusters to serve villages or remote communities. Their low power capacity (1-20kVA) matches the needs of rural households and small businesses (e.g., kiosks, small farms), and they can be easily integrated with solar mini-grids—a common solution in off-grid African areas. Three phase transformers are only used in rural areas with specific high-power needs, such as large agricultural cooperatives or rural industrial zones.

How do voltage stability and reliability compare between the two?

Three phase transformers offer superior voltage stability and reliability, making them critical for applications where consistent power is non-negotiable. The three out-of-phase waveforms ensure that the total power delivered remains constant, reducing voltage sags and surges that can damage sensitive equipment. This is particularly important for African industries like telecommunications, manufacturing, and healthcare (e.g., hospitals with medical equipment). Single phase transformers, while reliable for light loads, are more prone to voltage fluctuations when the load changes (e.g., multiple appliances turning on simultaneously), which can affect the performance of electronics—though this is rarely a problem for residential use.

What are the maintenance requirements for single phase vs three phase transformers?

Single phase transformers have minimal maintenance needs, which is a key advantage for African users with limited resources. Regular checks include inspecting wiring connections, cleaning the casing, and monitoring oil levels (for oil-immersed models)—tasks that can be performed with basic tools. Three phase transformers require more frequent and specialized maintenance: phase alignment checks, insulation resistance testing, and monitoring of load balance across all three phases. They also have more complex internal components (e.g., three sets of windings), which increases the risk of mechanical or electrical failure if not properly maintained. Many African industrial facilities opt for annual maintenance contracts for three phase units to ensure longevity.

Which transformer is more cost-effective in the long run?

For low-power applications (residential, small businesses), single phase transformers are more cost-effective in the long run. Their lower upfront cost, minimal installation expenses, and low maintenance fees offset any slight inefficiency. For high-power applications (industrial, large-scale commercial), three phase transformers are the more economical choice. While their upfront and installation costs are higher, their superior efficiency reduces energy bills significantly over time—often recouping the initial investment within 2-3 years. For example, a 100kVA three phase transformer in an African factory can save thousands of dollars annually in electricity costs compared to using multiple single phase units to meet the same load.

Can single phase transformers be used for small-scale industrial applications in Africa?

Single phase transformers can be used for very small-scale industrial applications in Africa, such as micro-enterprises (e.g., tailoring shops, small bakeries) with power needs below 10kVA. However, they are not suitable for most small-scale industries (e.g., small manufacturing plants, medium-sized farms with irrigation pumps) that require 10kVA or more. Using multiple single phase transformers to replace a single three phase unit is inefficient, costly, and increases the risk of power imbalances. For African small businesses looking to scale, investing in a three phase transformer early can avoid costly upgrades later and ensure reliable power for growing operations.

How do the size and weight differ between single phase and three phase transformers?

Single phase transformers are significantly smaller and lighter than three phase transformers of the same power capacity. A 10kVA single phase unit typically weighs 50-80kg and has a compact design, making it easy to transport and install in tight spaces (e.g., on utility poles or in small electrical rooms). A 10kVA three phase transformer, by contrast, weighs 150-250kg and requires more space for installation. This size and weight difference is a critical factor for African projects in remote areas, where transportation is often challenging (e.g., rural villages accessible only by dirt roads). Single phase units can be carried by hand or transported on small vehicles, while three phase units may require trucks or specialized equipment.

Which transformer is compatible with solar power systems in Africa?

Both single phase and three phase transformers are compatible with solar power systems in Africa, but the choice depends on the system’s size and application. Single phase transformers are used with small solar mini-grids (1-20kVA) that power residential areas or small communities. They can be easily integrated with solar inverters to convert DC power from solar panels to AC power for household use. Three phase transformers are used with large-scale solar farms (100kVA+) or commercial solar systems (e.g., solar-powered factories, office buildings). They work with three phase inverters to deliver high-power AC electricity, making them suitable for utility-scale solar projects—an increasingly important sector in Africa’s renewable energy transition.

How do fault risks and downtime compare?

Single phase transformers have lower fault risks due to their simpler design (fewer components mean fewer points of failure). Common issues like winding damage or short circuits are easier to diagnose and repair, resulting in minimal downtime—often a few hours. Three phase transformers, while more reliable overall for high loads, have higher fault risks if phase balance is disrupted (e.g., a damaged winding in one phase). Faults in three phase units can cause significant downtime (1-3 days) because they require specialized testing equipment and skilled technicians to repair. For African businesses, this means that three phase transformers should be paired with backup power solutions (e.g., generators) to avoid costly production losses.

Which transformer is more widely available in African markets?

Single phase transformers are more widely available in African markets, with local manufacturers and international suppliers offering a wide range of capacities. They are stocked by electrical retailers in urban and rural areas, making them easy to source for residential and small-scale projects. Three phase transformers are less commonly available in rural areas but are readily accessible in major African cities (e.g., Lagos, Nairobi, Johannesburg) and industrial hubs. Many African transformer manufacturers specialize in three phase units for industrial clients, and international suppliers often have regional warehouses to meet demand for large-scale projects. For remote industrial projects, advance ordering is recommended to ensure timely delivery.

How do they perform in extreme weather conditions in Africa?

Both single phase and three phase transformers are designed to withstand Africa’s extreme weather conditions, but their performance depends on the type (oil-immersed vs. dry-type) and quality of construction. Oil-immersed transformers (common for both types) have excellent heat dissipation, making them suitable for hot African climates (temperatures up to 45°C). They are also resistant to dust and humidity, which is important for areas with high rainfall or arid conditions. Dry-type transformers, while less common in Africa due to higher cost, are ideal for coastal areas with saltwater exposure (e.g., West African coastal cities) as they are corrosion-resistant. Three phase transformers, due to their larger size, may require additional cooling systems in extremely hot environments to maintain efficiency.

What factors should African businesses consider when choosing between single phase and three phase transformers?

African businesses should prioritize four key factors: 1) Load capacity: Assess current and future power needs (single phase for <10kVA, three phase for >10kVA). 2) Application: Residential/small business vs. industrial/large-scale commercial. 3) Infrastructure: Availability of three-phase power grids (common in urban areas, limited in rural regions). 4) Budget: Upfront costs, installation fees, and long-term energy savings (three phase is more cost-effective for high loads). Additionally, consider local maintenance availability, climate conditions (e.g., heat, humidity), and compliance with IEC standards. For example, a Nairobi-based manufacturing plant would opt for a three phase transformer, while a rural Ugandan kiosk would choose a single phase unit—aligning with their specific needs and local conditions.