Safety is non-negotiable when it comes to oil immersed transformers. From installation to daily operation, adherence to strict precautions—including proper handling, fire prevention, routine maintenance, environmental protection, and thorough cleaning—ensures the safety of personnel, protects equipment integrity, and minimizes environmental impact.

With years of industry expertise in transformer safety, this guide distills critical best practices for installing and operating oil immersed transformers. Whether you’re an electrical engineer, maintenance technician, or facility manager, these actionable insights will help you mitigate risks and ensure reliable, safe operation.

Contents

hide

Transformer Touchdown: Safe Installation of Oil-Filled Units

Installing an oil immersed transformer is no small feat—these heavy-duty units (often weighing several tons) require meticulous planning, specialized equipment, and skilled execution. A single misstep can lead to equipment damage, safety hazards, or costly delays. Below is a step-by-step framework for safe, successful installation.

Site Preparation: Lay the Groundwork

Before the transformer arrives, ensure the installation site is ready to support its weight and operational needs:

- Foundation Verification: Confirm the concrete pad is level, crack-free, and rated to bear the transformer’s full weight (including oil). Use load-bearing calculations to avoid structural failure.

- Clearance Compliance: Maintain minimum clearance around the unit (per manufacturer specs and local codes)—typically 3–5 feet for maintenance access and 10 feet from overhead power lines or obstacles.

- Access Route Planning: Clear a path for delivery vehicles and lifting equipment, ensuring the route can support heavy loads (e.g., reinforce weak pavement). Remove debris, low-hanging branches, or other obstacles.

A costly lesson from past projects: An installation was delayed 24 hours when the access route wasn’t properly reinforced, causing a delivery truck to get stuck. Proper site prep eliminates such risks.

Transportation & Lifting: Handle with Care

Moving the transformer from delivery truck to installation site requires precision and safety:

- Transport Safety: Use a trailer rated for the transformer’s weight (add 20% buffer for oil and accessories). Secure the unit with heavy-duty straps to prevent shifting, and use spotters to guide the driver through tight spaces.

- Weather Considerations: Avoid transporting or lifting in extreme weather (high winds >25 mph, heavy rain, or freezing temperatures) to prevent slips or equipment instability.

- Crane & Rigging Protocol:

- Select a crane with a capacity 30% higher than the transformer’s weight (accounting for lift radius and rigging).

- Inspect slings, shackles, and hooks for wear or damage—never use compromised equipment.

- Develop a lift plan with a designated director: Lift slowly to avoid swinging, use tag lines for control, and ensure no personnel are under the load.

| Lift Step | Critical Action | Safety Check |

|---|---|---|

| Rigging Attachment | Secure slings to manufacturer-designated lift points | Double-check connections for tightness |

| Area Clearance | Evacuate the lift zone of non-essential personnel | Verify no obstacles in the lift path |

| Test Lift | Raise the transformer 6–12 inches to check balance | Confirm stability before full elevation |

| Positioning | Guide the unit to the foundation using tag lines | Align with mounting holes before lowering |

Final Positioning & Securing

Once the transformer is on-site, complete the installation with these critical steps:

- Leveling: Use a precision level to ensure the unit is perfectly horizontal (max 0.5° tilt) to prevent oil pooling and ensure proper cooling.

- Anchoring: Secure the transformer to the foundation with torque-rated anchor bolts (follow manufacturer specs) to resist wind, seismic activity, or accidental impact.

- Post-Installation Inspection: Check for damage (e.g., dented tanks, cracked bushings) or oil leaks. Verify all components (valves, gauges, cooling systems) are intact and properly positioned.

A near-miss in a past project: A transformer tipped during final positioning because anchor bolts weren’t tightened to specification. No injuries occurred, but the unit sustained minor damage—reinforcing the importance of strict adherence to torque guidelines.

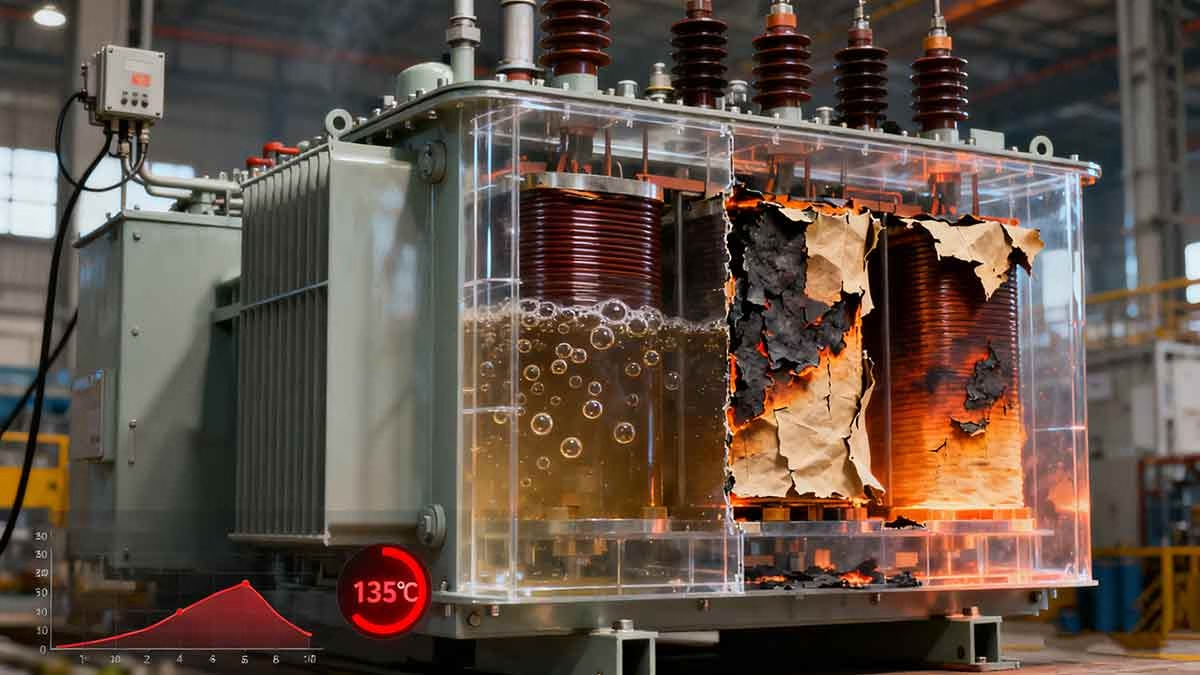

Fire and Oil Don’t Mix: Preventing Transformer Fires

Oil immersed transformers pose inherent fire risks—mineral oil (the most common insulating fluid) has a low flash point (~160°C) and can ignite if exposed to excessive heat or electrical faults. Preventing fires requires a proactive approach to address the “fire triangle” (fuel, oxygen, heat) and implement robust safety systems.

Mitigate Fuel Risks: Oil Maintenance

Transformer oil is both an insulator and a potential fuel—keep it in optimal condition to reduce fire risk:

- Routine Oil Testing: Conduct annual tests (dissolved gas analysis, moisture content, acidity) to detect degradation or contamination. Replace oil if DGA reveals abnormal gas levels (e.g., acetylene indicating arcing).

- Oil Level Monitoring: Maintain oil at the manufacturer-recommended level—low levels expose windings to air, increasing overheating risk, while overfilling can cause leaks.

- Eco-Friendly Fluid Alternatives: For high-risk areas (e.g., near buildings or water sources), use fire-resistant fluids (silicone or natural ester-based oils) with flash points >300°C.

In a recent substation upgrade, switching from mineral oil to natural ester fluid reduced fire risk by 60%—a small investment that yielded significant safety dividends.

Limit Oxygen Exposure: Sealed Systems

While oxygen can’t be eliminated entirely, minimizing contact with oil reduces combustion potential:

- Sealed Tank Design: Use transformers with hermetically sealed tanks to prevent air ingress, which degrades oil and increases fire risk. Inspect seals and gaskets quarterly for wear.

- Nitrogen Blanketing: For critical units, install nitrogen gas blankets above the oil to displace oxygen. Monitor nitrogen pressure weekly to ensure effectiveness.

Control Heat: Temperature Management

Overheating is the leading cause of transformer fires—implement these cooling and monitoring measures:

- Cooling System Maintenance: Clean radiators and fans monthly to remove dust, debris, or oil buildup. Test coolant pumps quarterly to ensure proper flow.

- Temperature Monitoring: Install dual sensors (oil and winding temperature) with alarms set at 90°C (warning) and 110°C (critical). For smart transformers, integrate real-time monitoring with facility management systems.

- Load Management: Avoid sustained overloading (never exceed 110% of rated capacity). Balance loads across phases to prevent hot spots in windings.

| Temperature Range | Action Required |

|---|---|

| <90°C | Continue routine monitoring |

| 90–110°C | Reduce load by 20%; inspect cooling system |

| 110–130°C | Emergency load reduction; investigate root cause |

| >130°C | Immediate shutdown and inspection |

Fire Detection & Suppression

Even with preventive measures, prepare for worst-case scenarios:

- Detection Systems: Install heat and smoke detectors within 10 feet of the transformer. For outdoor units, use flame detectors with UV/IR sensors to detect fires early.

- Suppression Systems: Deploy automatic systems tailored to transformer type:

- Indoor units: Clean-agent suppression (e.g., FM-200) to avoid water damage.

- Outdoor units: Water spray or foam systems (ensure coverage of the entire tank and surrounding area).

- Fire Barriers: For multiple transformers, install 4-hour fire-rated walls to prevent fire spread.

The Transformer Whisperer: Safe Operation Practices

Operating an oil immersed transformer safely requires technical knowledge, vigilant monitoring, and respect for its power. By “speaking its language” (understanding electrical parameters and performance cues), you can identify issues early and avoid hazards.

Monitor Key Performance Metrics

Treat your transformer like a high-performance machine—track these metrics daily:

- Electrical Parameters: Monitor input/output voltage (±1% of rated voltage), current balance (max 5% difference between phases), and power factor (target 0.85–0.95).

- Temperature Trends: Record oil and winding temperatures daily. Sudden increases (≥10°C in 24 hours) indicate issues (e.g., cooling system failure or internal faults).

- Dissolved Gas Analysis (DGA): Interpret DGA results to detect hidden problems:

| Gas | Abnormal Level Indication |

|---|---|

| Hydrogen (H₂) | Partial discharge or overheating |

| Methane (CH₄) | Low-temperature winding heating |

| Acetylene (C₂H₂) | Internal arcing (critical issue) |

| Ethylene (C₂H₄) | High-temperature winding damage |

Routine Operational Checks

Implement a daily/weekly inspection routine to catch issues early:

- Visual Inspections: Look for oil leaks (check valve connections and gaskets), cracked bushings, or discolored paint (signs of overheating). Listen for unusual noises—buzzing louder than normal may indicate core issues, while crackling suggests arcing.

- Cooling System Verification: Ensure fans/pumps are operating smoothly. Check for debris in radiators that could impede airflow.

- Gauge Readings: Record oil pressure, level, and temperature. Note any deviations from baseline values.

A past experience: A technician noticed a slight hum change during a daily check, leading to the discovery of a loose connection before it caused an arc fault. Trust your senses—they’re valuable safety tools.

Emergency Response Protocols

Know how to handle common operational emergencies:

- Overheating: Reduce load immediately; if temperatures don’t stabilize, shut down and inspect cooling systems or internal windings.

- Unusual Noises: Shut down the transformer if crackling, popping, or loud humming occurs—these may signal internal faults.

- Pressure Spikes: Sudden pressure increases (indicated by relief valve activation) suggest internal arcing or short circuits. Evacuate the area and initiate emergency shutdown.

Safety Protocols for Personnel

Never compromise on safety when working near or on transformers:

- Lockout/Tagout (LOTO): Always de-energize, lock, and tag the transformer before performing maintenance. Verify de-energization with a voltage tester—never assume the unit is off.

- Personal Protective Equipment (PPE): Mandate insulated gloves (Class 2 or higher), safety glasses, flame-resistant clothing, and steel-toe boots for all personnel working near the transformer.

- Training: Ensure all operators and technicians complete certified transformer safety training. Conduct annual refresher courses to reinforce protocols.

Green and Clean: Environmental Safety for Oil Transformers

Oil immersed transformers can pose environmental risks if not managed properly—oil leaks or improper disposal can contaminate soil, water, and air. Implement these eco-friendly practices to minimize your environmental footprint and comply with regulations (e.g., EPA, EU REACH).

Leak Prevention & Detection

Preventing oil spills is the first line of environmental defense:

- Seal Maintenance: Inspect gaskets, valves, and flange connections quarterly. Replace worn seals with high-quality, oil-resistant materials.

- Leak Monitoring: Install oil level sensors with low-level alarms to detect leaks early. For outdoor units, use ground sensors to detect oil seepage into soil.

- Pressure Checks: Monitor tank pressure monthly—sudden drops indicate leaks, while increases may signal internal faults.

A small leak detected during a routine inspection prevented a major contamination incident at a facility near a wetland—prompt repairs avoided costly cleanup and regulatory fines.

Secondary Containment Systems

Even with leak prevention, install containment to catch spills:

- Containment Pits: Design pits under the transformer to hold 110% of the total oil volume (per EPA requirements). Line pits with impermeable materials (e.g., HDPE liners) to prevent soil contamination.

- Double-Walled Tanks: For high-risk areas (e.g., near water bodies), use double-walled tanks with interstitial monitoring—alarms trigger if oil leaks into the gap between walls.

- Oil-Water Separators: Install separators in drainage systems to capture oil before it reaches stormwater or wastewater systems.

Eco-Friendly Oil Options

Reduce environmental impact by choosing sustainable insulating fluids:

- Biodegradable Oils: Vegetable-based or natural ester oils break down 90% within 28 days if spilled, compared to <10% for mineral oil.

- Recycled Oils: Use reclaimed transformer oil (processed to meet industry standards) for top-ups or replacements—reduces waste and carbon footprint.

Proper Waste Management

Dispose of oil, filters, and contaminated materials responsibly:

- Oil Disposal: Use licensed waste management companies to recycle or dispose of used oil. Never dump oil in drains, soil, or landfills.

- Contaminated Materials: Treat rags, filters, and absorbents as hazardous waste. Seal them in leak-proof containers and transport to certified disposal facilities.

- Record-Keeping: Maintain detailed records of oil purchases, tests, and disposal for 3–5 years to demonstrate regulatory compliance.

Transformer Spring Cleaning: Maintenance & Cleaning Best Practices

Regular cleaning and maintenance extend transformer lifespan, improve efficiency, and reduce safety risks. Unlike household cleaning, transformer maintenance requires specialized procedures to handle oil, contaminants, and electrical components safely.

Pre-Cleaning Preparation

Before starting any cleaning work:

- De-Energize & Secure: Follow LOTO procedures to de-energize the transformer. Ground the unit to discharge residual electricity.

- Safety Setup: Wear PPE (insulated gloves, goggles, chemical-resistant clothing) and ensure proper ventilation (especially for indoor units).

- Gather Equipment: Use oil pumps, filtration systems, environmentally friendly solvents, absorbent materials, and leak-proof containers.

Oil Maintenance: Drain, Filter, or Replace

Transformer oil degrades over time—clean or replace it to maintain insulation and cooling:

- Oil Testing: Analyze samples to determine if filtration (for minor contamination) or full replacement (for heavy degradation) is needed.

- Draining Process: Use a dedicated pump to drain oil into sealed containers. Avoid splashing, and use absorbents to clean spills immediately.

- System Flushing: Flush the tank with clean oil to remove sludge, varnish, or debris. For mineral oil systems, use compatible flushing agents to dissolve residues.

| Oil Condition | Recommended Action |

|---|---|

| Slightly degraded (low moisture/acidity) | Filter and reuse |

| Moderately degraded (high dissolved gases) | Recondition via vacuum dehydration |

| Heavily contaminated (water/particles) | Full replacement + tank flushing |

Component Cleaning

With oil drained, clean key components to remove buildup:

- Tank Interior: Wipe down the tank with lint-free cloths and mild solvents. Avoid abrasive materials that could scratch the tank lining.

- Radiators & Cooling Fins: Use high-pressure water (low psi) or compressed air to remove dust, dirt, and oil buildup. Ensure fins are free of blockages to maintain cooling efficiency.

- Bushings & Insulators: Clean with a damp cloth and dielectric cleaner to remove dust or contamination. Inspect for cracks—replace damaged bushings immediately.

- Core & Coils: If accessible, gently vacuum dust from core and coils. Avoid touching windings to prevent insulation damage.

A transformer that hadn’t been cleaned in a decade had radiators clogged with sludge—after cleaning, its cooling efficiency improved by 35%, reducing operating temperatures by 15°C.

Refilling & Post-Maintenance Testing

After cleaning, restore the transformer to service safely:

- Refilling: Use clean, dry oil that meets manufacturer specifications. Fill slowly to avoid trapping air bubbles (which reduce insulation effectiveness).

- Oil Treatment: Degas and dehydrate oil using vacuum processing to remove moisture and air.

- Electrical Testing: Conduct insulation resistance (IR) testing and power factor testing to verify system integrity. For large transformers, perform turns ratio testing to ensure winding accuracy.

- Break-In Period: Monitor the transformer closely for the first 72 hours of operation. Check for leaks, abnormal temperatures, or unusual noises.

Documentation

Record all maintenance activities in a centralized log:

- Detail oil test results, cleaning procedures, and parts replaced.

- Update the asset management system with maintenance dates and next scheduled service.

- Conduct a post-maintenance review to identify process improvements (e.g., adjusting cleaning frequency based on operating conditions).

Conclusion

Safe installation, operation, and maintenance of oil immersed transformers require a holistic approach—combining technical expertise, proactive monitoring, and strict adherence to safety and environmental regulations. By following the guidelines outlined above, you can protect personnel, extend equipment lifespan, minimize environmental impact, and ensure reliable power distribution.

Remember: Safety is a continuous process, not a one-time task. Regular training, routine inspections, and a culture of vigilance are the keys to mitigating risks and maximizing the performance of your oil immersed transformers.