Voltage Handling Capabilities: Power vs. Distribution Transformers

Power Transformers: High-Voltage Workhorses of Bulk Transmission

- Primary Voltage Range: 69 kV to 1,200 kV (for ultra-high voltage applications)

- Secondary Voltage Output: Typically steps down to sub-transmission voltages (e.g., 69 kV to 138 kV) for regional distribution

- Insulation Requirements: Advanced dielectric systems, including oil-impregnated paper insulation and SF6 gas-insulated components, to withstand voltage stress

- Voltage Regulation: Equipped with on-load tap changers (OLTC) for real-time voltage adjustment under full load—critical for maintaining stability in dynamic grid conditions. I recall retrofitting a 500 kV transformer with a digital OLTC in 2021, reducing voltage fluctuations by 30% for a growing industrial corridor.

Distribution Transformers: Low-Voltage Enablers of Consumer Power

| Aspect | Primary Voltage Input | Secondary Voltage Output |

|---|---|---|

| Voltage Range | 4 kV to 34.5 kV | 120/240 V to 480 V |

| Insulation Design | Simplified dielectric systems | Standard low-voltage insulation with surge protection |

| Basic Impulse Level (BIL) | Calibrated for medium-voltage resilience | Optimized for end-user safety (e.g., 60 kV BIL for residential units) |

- Voltage Regulation: Most rely on off-load tap changers (adjusted during maintenance) or fixed tap positions, as frequent voltage adjustments are less critical for local distribution.

- Grid Impact: Directly influences the layout of distribution lines, transformer bank sizing, and load balancing in neighborhood networks. In urban areas, we often deploy smaller, modular distribution transformers to accommodate dense load concentrations.

Distinct Roles in the Electrical Grid Ecosystem

Power Transformers: The Backbone of Bulk Power Transfer

- Step-Up Conversion: At power plants, boosting generator output (typically 10–30 kV) to high transmission voltages (69 kV+), reducing line losses during long-distance transport. A coal-fired plant I worked with in 2020 used 300 kV power transformers to cut transmission losses by 40% compared to older, lower-voltage systems.

- Bulk Power Routing: Facilitating power exchange between regional grids and balancing supply-demand across geographies.

- Grid Interconnection: Enabling integration of large-scale renewable energy projects (e.g., wind farms, solar parks) into the transmission network by matching their output voltages to grid standards.

Distribution Transformers: The Final Link to End Users

- Voltage Step-Down: Converting medium voltages from sub-transmission lines to usable levels for homes (120/240 V), offices (208/240 V), and small businesses (480 V).

- Load Distribution: Serving discrete geographic areas (e.g., neighborhoods, industrial parks) and adapting to variable load patterns (e.g., peak demand during summer cooling).

- Reliability Assurance: Providing redundancy and fault isolation to minimize outages. During a 2022 storm, distributed transformers in a coastal community prevented widespread blackouts by isolating damaged sections of the grid.

| Function | Power Transformer | Distribution Transformer |

|---|---|---|

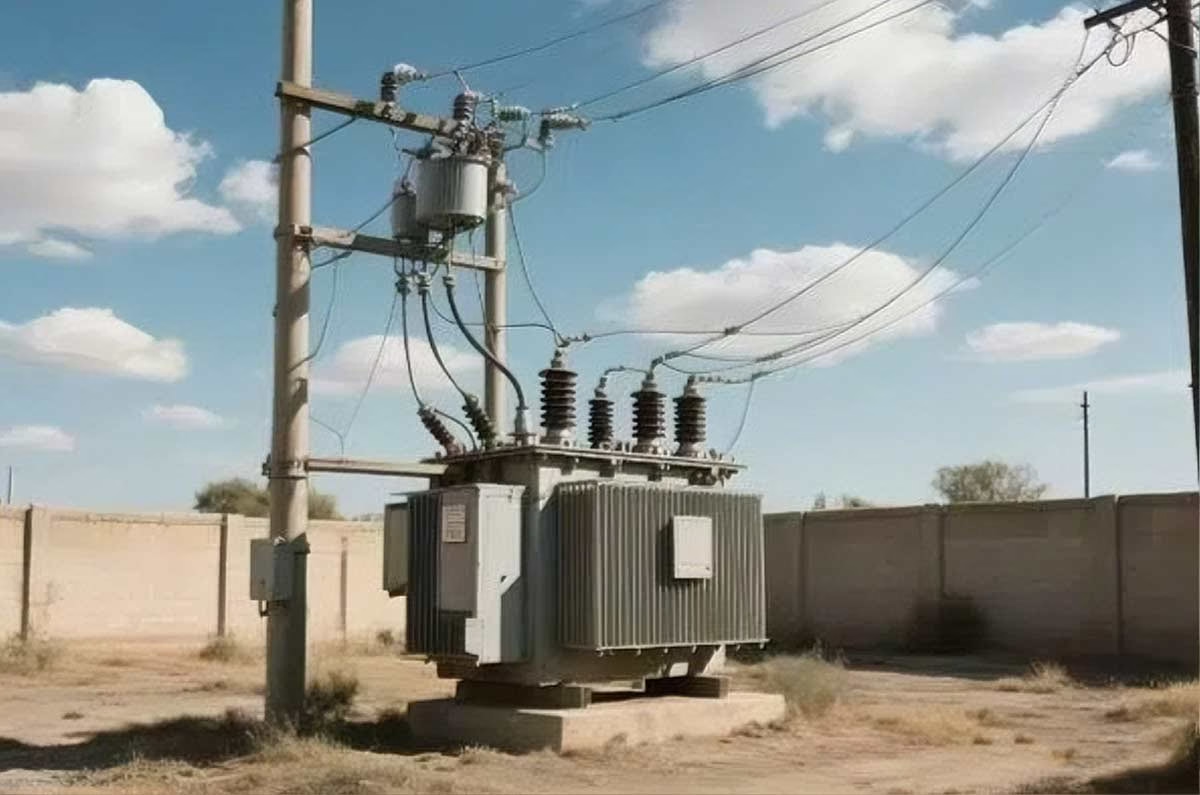

| Typical Location | Power plants, bulk substations | Utility poles, pad-mounted units, underground vaults |

| Power Capacity | 10 MVA to 5,000 MVA | 5 kVA to 5 MVA |

| Primary End Users | Regional grids, large industrial facilities | Residential buildings, small businesses, commercial complexes |

Evolving Roles in Modern Grids

- Power Transformers: Adapting to integrate high-penetration renewable energy (e.g., offshore wind) and support grid stability through advanced monitoring and control systems.

- Distribution Transformers: Evolving to handle bi-directional power flow from distributed energy resources (e.g., rooftop solar, battery storage)—a shift I’ve observed in smart grid projects where transformers now require enhanced thermal and electrical resilience.

Design and Construction: Tailored for Specialized Demands

Core and Winding Design

- Power Transformers:

- Utilize shell-type cores for superior mechanical strength and flux control, critical for high-voltage operation.

- Incorporate complex winding configurations (e.g., helical, disc-wound) with continuously transposed conductors (CTC) to minimize eddy current losses.

- Feature large core cross-sections and high-grade materials (e.g., amorphous steel, grain-oriented silicon steel) to reduce core losses. In a 2021 project, switching to amorphous steel cores cut a 400 kV transformer’s no-load losses by 25%.

- Distribution Transformers:

- Employ simpler core-type designs for cost-effectiveness and manufacturability.

- Use standardized winding arrangements (e.g., layer-wound) with copper or aluminum conductors—balancing conductivity and cost.

- Optimize core size for typical load profiles, prioritizing compactness for pole-mounted or underground installation.

Cooling Systems

| Aspect | Power Transformer | Distribution Transformer |

|---|---|---|

| Cooling Methods | ONAN (Oil Natural, Air Natural), ONAF (Oil Natural, Air Forced), OFAF (Oil Forced, Air Forced), ODAF (Oil Forced, Directional Air Forced) | Primarily ONAN; some dry-type units use air convection |

| Oil Volume | 1,000+ gallons (for large units) | 50–500 gallons (or dry-type construction) |

| Cooling Infrastructure | Extensive radiator banks, forced-oil pumps, and heat exchangers | Simple tank design with finned surfaces for natural convection |

Tap Changers and Terminals

- Power Transformers: Equipped with sophisticated OLTCs (on-load tap changers) for voltage regulation under full load. These units feature mechanical interlocks, oil filtration systems, and remote monitoring to ensure reliability. I once led a retrofitting project where adding a digital OLTC to a 220 kV transformer improved voltage stability by 40% in a grid with fluctuating renewable energy inputs.

- Distribution Transformers: Typically use off-load tap changers (adjusted when de-energized) or fixed taps. Terminals are standardized for easy connection to distribution lines, with compact bushings designed for low-voltage safety.

Monitoring and Protection

- Power Transformers: Integrate advanced monitoring systems for temperature, dissolved gas analysis (DGA), partial discharge, and oil quality. These systems feed data into SCADA platforms, enabling predictive maintenance. In 2022, an online DGA system detected a fault in a 500 kV transformer’s winding—allowing us to repair it before catastrophic failure.

- Distribution Transformers: Feature basic protection (e.g., overload fuses, lightning arresters) and limited monitoring (e.g., temperature sensors in premium units). Modern smart grid deployments are adding IoT-enabled sensors for load tracking and fault detection.

Efficiency and Loss Considerations: Balancing Performance and Cost

Key Loss Types

- No-Load Losses (Core Losses): Occur when the transformer is energized, caused by hysteresis and eddy currents in the core. These losses are constant regardless of load.

- Load Losses (Copper Losses): Vary with load current squared, caused by resistance in the windings. These losses increase as the transformer approaches full load.

Efficiency Benchmarks and Optimization

| Aspect | Power Transformer | Distribution Transformer |

|---|---|---|

| Typical Efficiency | 99.5%–99.9% (at rated load) | 98%–99% (at rated load) |

| Optimal Load Range | 50%–70% of rated capacity | 35%–50% of rated capacity (reflecting variable consumer loads) |

| Industry Standards | IEC 60076-2024, IEEE C57.12.00 | DOE 10 CFR Part 431, EU Ecodesign Directive (2019/1781) |

- Power Transformers: Prioritize minimizing both core and load losses, as they operate continuously at high capacities. Advanced designs use:

- High-grade core materials (e.g., amorphous metal) to reduce no-load losses.

- CTC windings and optimized conductor cross-sections to lower load losses.

- Smart cooling systems that adjust fan/pump speed based on load, reducing auxiliary losses.

- Distribution Transformers: Balance efficiency with cost, as they are deployed in large numbers (millions worldwide). Optimization strategies include:

- Selecting cost-effective core steels (e.g., M4/M5 grade silicon steel) that meet minimum efficiency standards.

- Using aluminum conductors (vs. copper) to reduce material costs, with design adjustments to maintain acceptable losses.

- Implementing tank designs that enhance natural convection reduces the need for active cooling.

Maintenance and Monitoring: Ensuring Lifespan and Reliability

Routine Maintenance Schedules

- Power Transformers: Require frequent, comprehensive maintenance due to their critical role and complexity:

- Monthly: Visual inspections, cooling system checks, and DGA sampling.

- Quarterly: Electrical testing (e.g., insulation resistance, winding resistance) and OLTC maintenance.

- Annual: Full-scale inspection, oil filtration, and thermal imaging.

- Condition-based maintenance (CBM) programs use real-time data to prioritize repairs—reducing unplanned outages by 30% in fleets I’ve managed.

- Distribution Transformers: Follow simpler, less frequent schedules:

- Annual/Bi-annual: External inspections (for leaks, corrosion, and bushing condition) and basic electrical tests.

- “Run-to-failure” models are common for low-cost units, but smart grid deployments are shifting to predictive maintenance with IoT sensors.

Oil Testing and Analysis

- Power Transformers: Quarterly DGA testing to detect dissolved gases (e.g., methane, ethylene) that indicate internal faults. Furan analysis and moisture testing are also performed annually to assess insulation degradation.

- Distribution Transformers: Annual oil quality testing (e.g., dielectric strength, acidity) with DGA reserved for high-value or critical units.

Electrical and Physical Inspections

- Power Transformers: Regular electrical tests include power factor testing, frequency response analysis (FRA) to detect winding displacement, and tap changer contact resistance measurements. Physical inspections cover bushings, cooling systems, and tank integrity—often requiring scaffolding or specialized access equipment.

- Distribution Transformers: Electrical testing is limited to insulation resistance and turn ratio checks. Physical inspections focus on external components (e.g., connections, grounding, and oil level gauges) and can often be performed from the ground.

Tap Changer Maintenance

- Power Transformers: OLTCs require quarterly oil filtration, mechanical wear checks, and contact cleaning to prevent arcing. Digital OLTCs need software updates and calibration to maintain precision.

- Distribution Transformers: Off-load tap changers are inspected during scheduled outages, with maintenance limited to verifying tap position and connection integrity.

Documentation and Asset Management

- Power Transformers: Maintain detailed digital records (e.g., test results, maintenance logs, fault history) using asset management software. Trend analysis of DGA data and electrical test results enables predictive fault detection.

- Distribution Transformers: Documentation is often centralized in utility databases, with records focusing on installation date, location, and major repairs—reflecting their lower individual value and higher volume.

Conclusion

More FAQ About Power Transformer and Distribution Transformer

Q: What are the core differences between power transformers and distribution transformers?

A: The fundamental distinction lies in their roles in the power system: power transformers focus on bulk energy transmission over long distances, while distribution transformers deliver electricity to end-users. Power transformers operate at high voltage levels (above 33 kV) with capacities exceeding 200 MVA, optimized for maximum efficiency at full load due to stable, continuous operation. In contrast, distribution transformers work at lower voltages (below 33 kV, typically 230 V to 11 kV) with capacities under 200 MVA, designed for all-day efficiency to accommodate frequent load fluctuations. Their winding connections also differ: power transformers usually adopt star-delta configurations, while distribution transformers use delta-star connections.

Q: What is the definition and main function of a power transformer?

A: A power transformer is a static electrical device that converts AC voltage between different levels at the same frequency, playing a critical role in power generation and transmission links. Its primary functions are stepping up voltage from power plants to high levels (e.g., 110 kV to 400 kV) for efficient long-distance transmission (reducing energy losses) and stepping down voltage at substations for subsequent distribution. It is a core equipment in power plants and substations, handling bulk energy transfer with minimal load fluctuations.

Q: What is the definition and main function of a distribution transformer?

A: A distribution transformer is a static device in the power distribution network that steps down medium voltage to end-user-applicable levels (e.g., 11 kV to 440 V or 230 V). It is installed near load terminals (communities, commercial buildings, industrial sites) to provide immediate usable voltage for residential, commercial, and small industrial needs. Unlike power transformers, it operates 24/7 even under light loads, so its design prioritizes low no-load losses to ensure energy efficiency throughout the day.

Q: How do voltage levels and capacity ratings differ between the Power Transformer and Distribution Transformer?

A: Power transformers are engineered for high voltage applications, with typical ratings of 33 kV, 66 kV, 110 kV, 200 kV, or 400 kV and capacities ranging from hundreds of MVA to several thousand MVA. Distribution transformers target low to medium voltages, commonly 3.3 kV, 6.6 kV, 11 kV, 440 V, or 230 V, with capacities usually below 200 MVA (often under 500 kVA for most end-user scenarios). These differences are determined by their respective roles: long-distance bulk transmission requires high voltage/capacity, while end-user supply needs lower, safer voltage levels.

Q: What are the key design considerations for power transformers vs. distribution transformers?

A: Power transformer design focuses on high insulation levels (to withstand high voltage), advanced cooling systems (e.g., oil-forced air/water cooling) to handle large heat generation, and stable full-load operation. Core materials and winding conductors are optimized for minimal losses at continuous high loads. For distribution transformers, design priorities include compact size (for easy installation on poles or underground vaults), low no-load losses (due to 24/7 energization), simple cooling (oil or air-cooled), and durability against frequent load variations. Their core configurations often use classic “E” core designs for cost-effectiveness.

Q: What are the common cooling systems for power and distribution transformers?

A: Power transformers use advanced cooling systems due to high heat output: oil-immersed cooling (accounting for over 95% of installations due to low cost and reliability), oil-forced air forced (OFAF), or oil-forced water forced (OFWF) systems. Dry-type power transformers are used in fire-risk areas (mines, subways) with a voltage up to 35 kV. Distribution transformers employ simpler cooling: oil-immersed (most common) or air-cooled dry-type. Dry-type distribution transformers are preferred for indoor applications (commercial buildings, data centers) due to compact size and fire safety, while oil-immersed types are used outdoors for larger capacities.

Q: How to select the right transformer (power vs. distribution) for specific applications?

A: Selection depends on voltage level, capacity, application scenario, and load characteristics. For long-distance power transmission (power plant to substation), choose power transformers with high voltage (≥33 kV) and large capacity (≥200 MVA). For end-user supply (residential communities, hospitals, small factories), select distribution transformers with low voltage (≤11 kV) and capacity matching peak load demands. Key factors include load fluctuation frequency (distribution transformers for variable loads), installation environment (dry-type for indoor/fire-risk areas), and compliance with local standards (e.g., IEC 60076, ENERGY STAR).

Q: What are the main loss types of power and distribution transformers, and how to reduced?

A: Transformer losses include iron losses (core losses, constant regardless of load) and copper losses (winding losses, proportional to load square). Power transformers optimize loss matching at full load (iron losses = copper losses) since they operate continuously at high loads. Distribution transformers prioritize low iron losses (due to 24/7 operation) with optimal losses at 75% load. Reduction measures include using high-grade silicon steel for cores (reducing iron losses), optimizing winding conductor cross-sections (lowering copper losses), and adopting advanced insulation materials (e.g., SiC/GaN for power electronic transformers) to improve efficiency.

Q: What are the typical application scenarios of power transformers?

A: Power transformers are mainly used in power generation plants (stepping up generator voltage to transmission levels), transmission substations (voltage conversion between 33 kV to 400 kV), interregional power grids (interconnecting different voltage grades), and large industrial facilities (e.g., steel mills, refineries) requiring a bulk power supply. They are also essential for HVDC transmission corridors, which transfer power over ultra-long distances (e.g., offshore wind farms to onshore grids).

Q: What are the typical application scenarios of distribution transformers?

A: Distribution transformers are widely used in residential communities (stepping down 11 kV to 230 V/440 V), commercial buildings (malls, office towers), public facilities (hospitals, schools), small to medium-sized industrial plants (machinery, electronics), and remote areas (rural electrification). They are installed as pole-mounted, pad-mounted, or underground units, adapting to diverse environmental conditions (urban, rural, coastal) with corresponding protection measures (e.g., lightning arresters for outdoor units).

Q: How to maintain power and distribution transformers for long-term reliability?

A: Maintenance strategies differ based on transformer type: for power transformers, regular checks include oil quality testing (moisture, dielectric strength), insulation resistance measurement, cooling system inspection, and load monitoring. For distribution transformers, key tasks are monitoring no-load losses, checking terminal connections (to prevent overheating), inspecting insulation for aging, and cleaning cooling fins. Predictive maintenance using sensors and AI (monitoring temperature, vibration, and oil condition) is increasingly adopted to detect faults early and extend service life.

Q: How does grid modernization policy impact the demand for power and distribution transformers?

A: Grid modernization initiatives globally are driving transformer demand: in the U.S., the DOE’s Grid Resilience and Innovation Partnerships Program provides $7.6 billion for substation upgrades and transformer banks; in Europe, the Grid Action Plan requires $680 billion in grid investment by 2030, including EHV transformers for cross-border interconnection. Policies promoting decarbonization and renewable energy (e.g., IEA’s net-zero goals) increase demand for high-efficiency, high-voltage power transformers. Additionally, regulations on energy efficiency (e.g., ENERGY STAR) are pushing the replacement of old distribution transformers with super-efficient models.