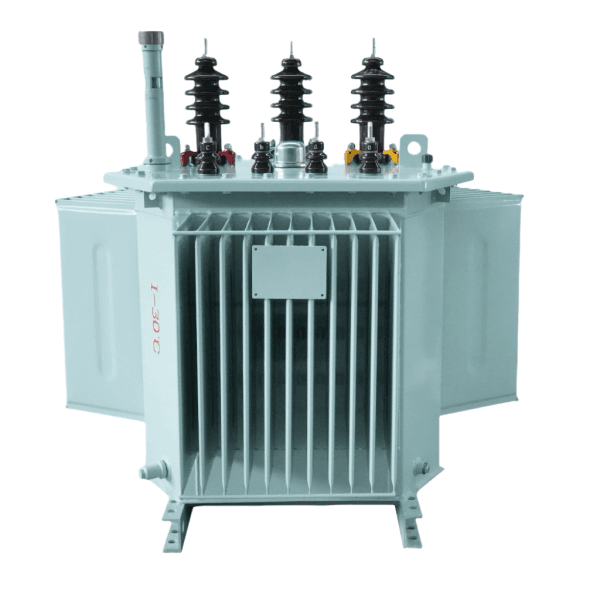

Description

Technical Specifications of Silicon Steel Core Transformers

1. Silicon Steel Core Properties of Planar Transformer

- Material Composition: Silicon alloy steel containing 1.0–4.5% Si and <0.08% C, optimized for:

- Low core losses (iron losses)

- High magnetic flux density (≥1.7T under 50Hz, per IEC 60404-8-4)

- High permeability, low coercivity, and enhanced resistivity

- Structural Advantages:

- Compact size and lightweight design

- Reduced material consumption (core, windings, insulation, and structural components)

- Simplified assembly and transportation

2. Compliance with National Standards

This product series complies with the following Chinese national standards:

- GB 1094: Power Transformers (equivalent to IEC 60076-1)

- GB/T 6451: Technical Parameters and Requirements for Three-Phase Oil-immersed Power Transformers

- GB 20052: Energy Efficiency Limits and Grades for Power Transformers (aligned with IEC 60076-20)

3. Energy Efficiency Classification

The series is categorized into three efficiency levels:

- S22 Class I Efficiency (NX1): Ultra-high efficiency (compatible with IEC 60076-20 Tier 3).

- S20 Class II Efficiency (NX2): Advanced efficiency (meeting DOE 2016 standards).

- S13 Class III Efficiency (NX3): Baseline efficiency (for cost-sensitive applications).

Structural Features of Planar Transformer

Technical Specifications of Power Transformers

1. Core Design

- High-grade grain-oriented silicon steel core:

- Low losses (no-load loss ≤0.9W/kg, per IEC 60404-8-4).

- Compact size, high mechanical strength, and superior short-circuit withstand capability (≥25kA/3s).

2. Winding Configuration

- Coil structure:

- HV windings: Circular/oval shape with polyvinyl acetal enameled wire (thermal class 180°C).

- LV windings: Flat wire or copper foil construction for enhanced short-circuit resistance (IEC 60076-5).

3. Connection & Performance

- Dyn11 connection group:

- Mitigates higher harmonics (THD ≤3% per IEEE 519).

- Robust load imbalance resistance (up to 10% phase imbalance).

- Ensures stable voltage regulation (±1.5% under dynamic loads).

4. Insulation & Sealing

- Vacuum oil impregnation:

- Eliminates air bubbles in windings (degassing rate ≥99.9%).

- Stabilizes dielectric strength (≥50kV AC/1min, per IEC 60296).

- Hermetically sealed corrugated tank:

- Dual-channel corrugated plates (wave depth >250mm) prevent plastic deformation and oil leakage.

- IP55 protection (IEC 60529) blocks moisture ingress, extending insulation lifespan by ≥30%.

5. Oil Maintenance & Longevity

- Fully sealed oil system:

- Zero contact with ambient air, eliminating oxidation and moisture absorption.

- Delays insulation aging (service life ≥40 years under IEC 60076-14 loading guidelines).