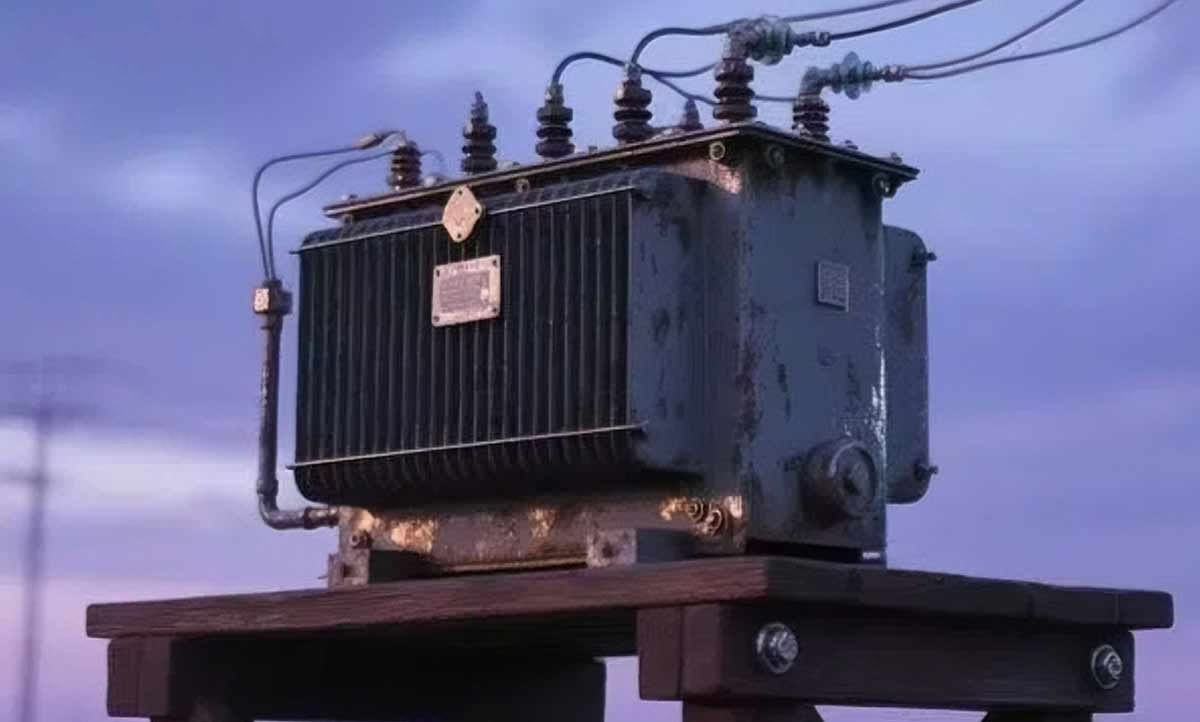

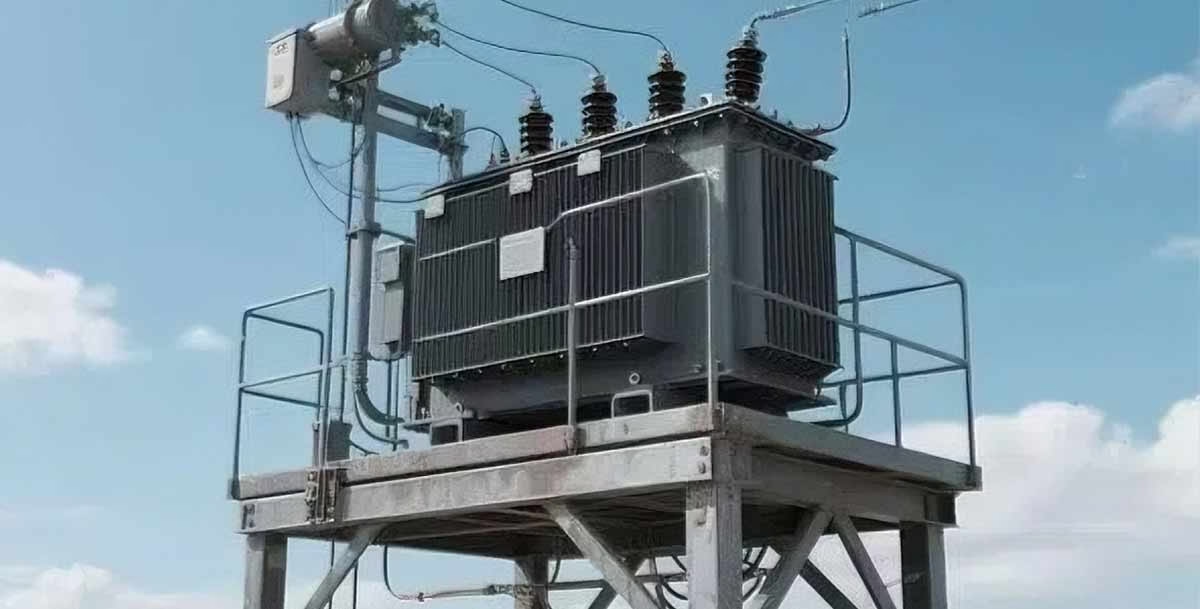

Safeguarding pad mounted transformer safety during installation and daily use relies on strategic planning, strict adherence to safety standards, consistent maintenance routines, and robust emergency readiness. These practices not only mitigate accident risks but also protect workers and the public while ensuring uninterrupted power delivery—critical for reliable community infrastructure.

Residential areas, commercial districts, and industrial zones all depend on these compact power hubs, making safety a non-negotiable priority. Below, we’ll explore actionable safety protocols, maintenance strategies, emergency responses, and emerging technologies that keep pad mounted transformers secure and efficient.

Contents

hide

What Are the Key Safety Protocols for Pad Mounted Transformer Installation?

Ever wondered what makes a pad mounted transformer installation safe for neighborhoods and workers alike? It’s far more than just placing equipment—it’s a careful balance of site planning, technical compliance, and community consideration.

Core safety protocols for installation include strategic site selection, reliable grounding systems, secure enclosure design, and clear safety labeling. These steps ensure the transformer is positioned to minimize hazards, protected from unauthorized access, and clearly identified for everyone’s awareness.

Let’s unpack these critical safety steps:

Site Selection: Choosing the Right Location

The success of a safe installation starts with picking the optimal spot.

Key Factors to Consider:

- Proximity to buildings (maintaining recommended safety distances)

- Easy access for future maintenance and repairs

- Protection against natural hazards like flooding or extreme weather

- Clearance from other utility lines and infrastructure

Proper Grounding: Your Invisible Safety Shield

Grounding acts as a critical defense against electrical faults and lightning strikes, diverting dangerous currents away from the transformer and surrounding areas.

Grounding Requirements:

- A low-resistance path to the earth for fault currents

- Appropriately sized grounding conductors to handle electrical loads

- Regular testing to ensure ongoing effectiveness

- Protection against corrosion (especially in damp or coastal environments)

Secure Enclosure Design: Keeping Hazards Contained

The transformer’s enclosure is the first barrier against tampering, accidents, and environmental damage.

Essential Enclosure Traits:

- Tamper-proof locks to prevent unauthorized entry

- Adequate ventilation to regulate temperature and prevent overheating

- Weather-resistant materials to withstand rain, snow, and extreme temperatures

- Impact-resistant construction to handle accidental collisions

Clear Labeling: Warnings That Save Lives

Proper labeling ensures anyone near the transformer understands potential risks and knows how to respond in an emergency.

Must-Have Labels:

- High-voltage warning signs (visible from all angles)

- Emergency contact information for utility providers

- Key transformer specifications (voltage rating, capacity)

- Basic safety instructions (e.g., “Do not touch” or “Keep children away”)

| Safety Aspect | Importance Level | Implementation Challenges |

|---|---|---|

| Site Selection | High | Space constraints in crowded city settings |

| Grounding | Critical | Poor soil conductivity, corrosion risks |

| Enclosure Design | High | Balancing security with maintenance access |

| Labeling | Medium | Keeping labels legible over time (sun, weather) |

I once led a complex installation in a bustling city neighborhood where space was at a premium. We had to navigate tight sidewalks, nearby residential buildings, and community concerns about aesthetics. Instead of placing the transformer in a visible, obtrusive spot, we worked with local urban planners to integrate it with existing greenery—using low-growing shrubs to screen it while maintaining full safety clearance.

Grounding proved tricky due to the area’s clay soil, which has high resistance. We solved this by installing deep-driven grounding rods (extending 10+ feet underground) and using a low-resistance backfill material to improve conductivity. It added extra time to the project, but knowing the transformer was protected against faults and lightning made it worthwhile.

For the enclosure, we opted for a sleek, neutral-colored design to avoid clashing with the neighborhood’s architecture. A local artist even painted a small mural on one side—depicting the area’s history—which turned a functional piece of equipment into a community asset. We also added QR codes to the labels, linking to multilingual safety guides (English, Spanish, and Vietnamese) to accommodate the neighborhood’s diverse population.

This project taught me that safe installation isn’t just about checking boxes—it’s about creative problem-solving and engaging with the community. By addressing both technical requirements and local concerns, we created an installation that was safe, reliable, and widely accepted.

How to Ensure Safe Daily Operation of Pad Mounted Transformers?

Walk past a pad mounted transformer in your neighborhood, and you might wonder: Is it operating safely? Operational safety isn’t just for utility workers—it impacts everyone who lives, works, or passes near these power hubs.

Ensuring secure daily use requires implementing strict access controls, proactive inspections, smart load management, and targeted public awareness campaigns. These measures work together to prevent accidents, preserve equipment integrity, and foster a safety-focused community.

Let’s explore the pillars of operational safety:

Access Control: Restricting Unauthorized Entry

Limiting access to pad mounted transformers is one of the simplest yet most effective safety measures.

Access Control Solutions:

- Keycard or electronic locks (replacing traditional padlocks for better security)

- Surveillance cameras in high-traffic or high-risk areas

- Low-profile fencing (where space allows) to create a physical barrier

- Bold “No Trespassing” or “High Voltage—Keep Out” signs

Regular Inspections: Catching Issues Early

Routine checks help identify small problems before they escalate into dangerous failures.

Inspection Checklist:

- Visual inspections for physical damage, vandalism, or signs of wear

- Thermal imaging scans to detect hidden hotspots (indicative of electrical issues)

- Oil level and quality testing (for liquid-filled transformers)

- Monitoring of electrical performance (voltage, current, and load levels)

Load Management: Balancing Power and Safety

Overloading is a common cause of transformer failure—proper load management prevents overheating and extends equipment life.

Load Management Tactics:

- Real-time monitoring systems to track load levels 24/7

- Load balancing across phases to distribute power evenly

- Strategic peak-demand management (e.g., shifting non-essential loads during busy periods)

- Proactive upgrades based on usage trends (avoiding overreliance on aging equipment)

Public Awareness: Empowering the Community

Educating the public about transformer safety turns residents into partners in protecting these critical assets.

Awareness Initiatives:

- Interactive safety presentations at local schools

- Community workshops for homeowners and small business owners

- Informational flyers distributed door-to-door (in multiple languages)

- Social media campaigns with short, engaging videos about safety dos and don’ts

| Safety Protocol | Primary Benefit | Implementation Challenge |

|---|---|---|

| Access Control | Prevents tampering and accidental injury | Balancing security with easy maintenance access |

| Regular Inspections | Detects issues before they become hazards | Scheduling checks in busy, high-traffic areas |

| Load Management | Avoids overheating and equipment failure | Requires investment in smart monitoring tools |

| Public Awareness | Reduces accidental interference | Engaging diverse communities with varying language needs |

I managed operational safety for a network of pad mounted transformers in a fast-growing suburban area a few years back. The biggest challenge was balancing rising power demands with the curiosity of new residents—many of whom were unfamiliar with transformer safety.

We rolled out a multi-layered access control system: physical locks were paired with smart sensors that sent real-time alerts to our team if someone tried to force entry. This caught several instances of kids attempting to open enclosures, allowing us to reach out to parents and reinforce safety messages before anyone got hurt.

For inspections, we started using drones equipped with thermal cameras. This let us quickly check transformers in hard-to-reach spots (like behind commercial buildings) without disrupting traffic or businesses. The drones helped us spot a hotspot in one transformer that would have gone unnoticed in a standard visual check—we fixed the issue during off-peak hours, avoiding a potential outage.

Load management became critical as new homes and businesses popped up. We installed smart meters that gave us real-time load data, allowing us to redistribute power across the network and plan upgrades before any transformer was overwhelmed. For example, we upgraded a transformer serving a new shopping center six months ahead of schedule, preventing overloading during the holiday season.

The public awareness campaign was the most rewarding part. We partnered with local schools to launch a “Power Safety Heroes” program—kids learned about transformer safety through games and activities, then took home worksheets to share with their families. Within a year, reports of accidental interference dropped by 60%.

One resident even called our emergency line after hearing a strange buzzing from a transformer near his home. Thanks to our campaign, he knew not to investigate himself—he just reported it. We found a loose connection that would have led to a failure within days. That call saved us from a potential outage and highlighted the power of community engagement.

How to Maintain Pad Mounted Transformers for Optimal Safety?

Is the pad mounted transformer in your area getting the care it needs? Proper maintenance isn’t just about keeping equipment running—it’s a critical safety measure that prevents hazards and ensures long-term reliability.

To keep pad mounted transformers in top condition, you need a comprehensive maintenance strategy: regular inspections, preventive care, condition monitoring, and prompt repairs. These practices work together to minimize safety risks, extend equipment life, and keep power flowing smoothly.

Let’s break down the key components of an effective maintenance plan:

Regular Inspections: The Foundation of Safety

Routine checks are your first line of defense against potential hazards.

Inspection Focus Areas:

- Visual checks for physical damage, leaks, or signs of corrosion

- Infrared scanning to identify hidden hotspots in windings or connections

- Oil analysis (for liquid-filled units) to check for contamination or degradation

- Insulation resistance tests to ensure electrical safety

Preventive Maintenance: Stopping Problems Before They Start

Scheduled maintenance tasks address wear and tear before it leads to failure.

Preventive Maintenance Tasks:

- Oil filtration or replacement (to remove moisture and contaminants)

- Replacement of worn gaskets and seals (to prevent leaks)

- Cleaning of cooling fins (to maintain proper heat dissipation)

- Tightening of electrical connections (to prevent arcing and hotspots)

Condition Monitoring: Keeping a Pulse on Equipment Health

Advanced monitoring systems provide real-time data about your transformer’s performance, letting you act proactively.

Key Monitoring Parameters:

- Oil and winding temperatures (to prevent overheating)

- Partial discharge activity (a sign of potential insulation failure)

- Dissolved gas analysis (detects internal faults early)

- Voltage and load levels (to avoid overloading)

Timely Repairs: Addressing Issues Quickly

When problems are detected, prompt action is critical to prevent small issues from becoming major hazards.

Repair Priorities:

- Oil leaks (which pose fire and environmental risks)

- Faulty bushings (a common cause of electrical failures)

- Cooling system malfunctions (leading to overheating)

- Issues with control or protection systems (compromising safety)

| Maintenance Aspect | Safety Impact | Operational Benefit |

|---|---|---|

| Regular Inspections | Identifies hazards before they escalate | Reduces unexpected downtime |

| Preventive Maintenance | Lowers risk of component failure | Extends transformer lifespan |

| Condition Monitoring | Enables proactive safety interventions | Optimizes maintenance scheduling (saves time/money) |

| Timely Repairs | Eliminates immediate safety threats | Minimizes service disruptions |

A few years ago, I oversaw a maintenance overhaul for a fleet of aging pad mounted transformers in a mid-sized city. The goal was to improve safety and reliability without causing widespread outages—no easy feat, since many of the transformers served critical facilities like hospitals and schools.

We started with a full audit: every transformer got a visual inspection, thermal scan, and oil analysis. This created a “health profile” for each unit, letting us prioritize maintenance. For example, transformers serving hospitals were moved to the front of the line, while those in residential areas with minor issues were scheduled for off-peak service.

Preventive maintenance was key. Many of the transformers had moisture-contaminated oil, which can cause internal corrosion. Instead of replacing the oil (which would require taking the transformer offline for days), we used a mobile oil reconditioning unit that cleaned the oil on-site. This cut downtime from 3-5 days to just 8 hours per transformer.

Condition monitoring transformed how we worked. We installed sensors on the most critical transformers that sent real-time data to our control center. One day, the system alerted us to unusual partial discharge activity in a transformer serving a children’s hospital. We scheduled emergency maintenance during a planned generator test at the hospital—so there was no disruption to patient care, and we fixed the issue before it caused a failure.

We also created a rapid-response repair team with a mobile workshop. Instead of transporting faulty transformers to a facility (which is time-consuming and risky), the team could make most repairs on-site. For example, when a transformer in a residential area developed an oil leak, the team arrived within 2 hours, contained the leak, and replaced the gasket—all while keeping the area safe for residents.

One success story stands out: our monitoring system flagged a transformer with unusual temperature spikes. When we inspected it, we found a developing internal fault that would have led to a catastrophic failure within weeks. We replaced the transformer during a planned neighborhood outage (scheduling it for a weekend to minimize impact), avoiding what could have been a dangerous emergency.

What Emergency Response Measures Apply to Pad Mounted Transformer Incidents?

What happens if a pad mounted transformer malfunctions? Emergencies like fires, leaks, or electrical faults require fast, coordinated action to protect the public and minimize damage.

Effective emergency response for pad mounted transformer incidents includes quick isolation of the affected area, safe power shutdown, collaboration with emergency services, and clear public communication. These steps are critical to reducing risks and resolving incidents efficiently.

Let’s outline the key elements of a strong emergency response plan:

Rapid Isolation: Securing the Area

The first step in any transformer emergency is to create a safe perimeter and keep people away from hazards.

Isolation Steps:

- Establish a safety zone (following local guidelines for high-voltage equipment)

- Restrict access to authorized personnel only (utility workers, emergency responders)

- Use physical barriers (cones, tape) and visible warning signs

- Coordinate with local police to manage crowds and traffic

Safe Power Shutdown: Cutting Off the Hazard

De-energizing the transformer is essential to stop the emergency from escalating.

Shutdown Protocol:

- Use remote disconnection if available (to avoid putting workers at risk)

- Follow strict manual shutdown procedures if remote access isn’t possible

- Verify that power is fully isolated (using voltage testers)

- Ground the transformer to discharge any residual electricity

Coordinated Response: Working with Emergency Teams

Transformer emergencies require collaboration between utility companies and local emergency services.

Key Partners in Response:

- Utility emergency crews (to handle technical aspects of the incident)

- Fire department (to address fires, leaks, or environmental hazards)

- Police (for crowd control and traffic management)

- Medical services (on standby for potential injuries)

- Environmental teams (to contain oil leaks or hazardous materials)

Public Communication: Keeping Everyone Informed

Clear, timely updates help prevent panic and ensure the public knows how to stay safe.

Communication Channels:

- Emergency alert systems (text messages, phone calls to affected areas)

- Social media updates (real-time information on the incident and response)

- Local news outlets (interviews or press releases to reach a wide audience)

- Door-to-door notifications (for small, densely populated areas)

| Response Element | Primary Objective | Potential Challenges |

|---|---|---|

| Rapid Isolation | Protect the public from immediate hazards | Managing curious onlookers in busy areas |

| Safe Power Shutdown | Stop the emergency from escalating | Minimizing service disruption to critical customers |

| Coordinated Response | Resolve the incident efficiently | Communication gaps between different agencies |

| Public Communication | Keep people safe and informed | Reaching non-English speakers or tech-challenged residents |

I experienced a challenging transformer emergency a few years ago: a pad mounted unit ignited in a bustling commercial area during peak business hours. The incident tested our emergency plan—and taught us valuable lessons about coordination and communication.

Our first move was to isolate the area. We arrived within 10 minutes and set up a 50-foot safety perimeter, but managing the crowd was tough—shoppers and business owners were curious, and some wanted to retrieve belongings from nearby stores. We worked with local police to gently redirect people and explain the risks, which helped keep the area secure.

Shutting down the power was a balancing act. The transformer served several businesses, including a small data center that couldn’t afford a long outage. Thanks to our smart grid system, we were able to reroute power to most customers within 15 minutes while isolating the faulty transformer. This minimized disruption and kept the data center online.

The coordinated response was impressive. Fire crews arrived within 5 minutes and quickly contained the small fire—using eco-friendly fire suppressants to avoid environmental damage. Our environmental team was on hand to clean up a small oil leak, and paramedics stood by in case of injuries (fortunately, there were none). The key to our success was regular joint training sessions with these teams—we knew each other’s roles and could communicate seamlessly.

Public communication was critical. We sent emergency alerts to everyone within a 1-mile radius, updating them on the situation and advising them to avoid the area. Our social media team posted real-time updates, which were shared by local news outlets. We also set up a temporary hotline for questions—this helped address concerns and prevent rumors from spreading.

After the incident, we realized we needed a better post-emergency communication plan. Residents and business owners wanted to know what caused the fire and how we were preventing future incidents. We held a community meeting a week later, shared our findings (a faulty connection), and outlined our new preventive maintenance steps. This transparency helped rebuild trust and reassure the community.

What Are the Latest Innovations and Future Trends in Pad Mounted Transformer Safety?

Technology is transforming pad mounted transformer safety—making these essential power assets smarter, more sustainable, and more reliable than ever before. From intelligent monitoring to eco-friendly materials, the latest innovations are reshaping how we protect workers, the public, and the environment.

Today’s top safety advancements include intelligent monitoring solutions, sustainable insulating compounds, advanced fire suppression systems, and IoT integration. Looking ahead, trends like AI-driven predictive maintenance, self-healing transformers, and enhanced cybersecurity will further elevate safety standards.

Let’s explore these game-changing developments:

Intelligent Monitoring Solutions: 24/7 Oversight

Modern transformers are equipped with sensors and smart technology that provide real-time insights into their health—catching issues before they become hazards.

Key Smart Features:

- Continuous temperature and load monitoring (with automated alerts for anomalies)

- Acoustic sensors that detect partial discharge (a early sign of insulation failure)

- Oil quality monitors that track contamination and degradation

- Cloud-based reporting dashboards for easy access to data

Sustainable Insulating Compounds: Safe for People and the Planet

Traditional transformer oils can be harmful to the environment if leaked—new materials are changing that, without sacrificing performance.

Innovative Materials:

- Biodegradable ester-based oils (safe for soil and water)

- Dry-type insulation systems (eliminating the risk of oil leaks entirely)

- Recyclable components (reducing environmental impact at end-of-life)

- Low-emission designs (minimizing carbon footprint)

Advanced Fire Suppression: Fast, Effective Hazard Control

New fire suppression technologies act quickly to contain fires before they spread—protecting nearby property and people.

Fire Safety Innovations:

- Automatic fire detection systems (triggering suppression within seconds)

- Eco-friendly fire-retardant fluids (non-toxic and non-corrosive)

- Rapid depressurization systems (reducing the risk of explosions)

- Integrated suppression mechanisms (built into the transformer enclosure)

IoT Integration: Connected for Enhanced Safety

The Internet of Things (IoT) is linking transformers to broader power networks, enabling smarter, more proactive safety management.

IoT Applications:

- Remote monitoring and control (allowing adjustments without on-site visits)

- Predictive analytics (using data to forecast maintenance needs)

- Integration with smart grids (optimizing load distribution to prevent overloading)

- Real-time fault detection (speeding up response times for emergencies)

| Innovation | Safety Benefit | Implementation Challenge |

|---|---|---|

| Intelligent Monitoring | Early detection of potential failures | Managing large volumes of data effectively |

| Sustainable Materials | Reduced environmental and health risks | Balancing cost with performance |

| Advanced Fire Suppression | Faster, more effective fire control | Integrating with existing transformer designs |

| IoT Integration | Comprehensive, real-time safety oversight | Protecting against cybersecurity threats |

I recently led a trial initiative to test these innovations in a suburban transformer network—and the results were eye-opening.

We retrofitted 10 transformers with intelligent monitoring sensors, and the data we collected was transformative. One transformer that had always performed “normally” started showing increased partial discharge activity—something we would have missed with standard inspections. We replaced the faulty insulation during a planned outage, avoiding a potential failure.

The sustainable insulating materials were a hit with the community, especially in an area with a strong focus on environmental protection. We replaced the mineral oil in one transformer with a biodegradable ester fluid—it not only reduced the risk of environmental damage but also improved thermal performance, letting the transformer handle 15% more load safely.

Our advanced fire suppression system was put to the test sooner than expected: a minor internal fault triggered the system, which activated within 3 seconds and suppressed the fire before it could spread. The transformer was back in service within 24 hours, with no damage to surrounding property.

IoT integration was the most impactful innovation. We connected all the transformers to a central dashboard, giving us a real-time view of the entire network. This let us optimize load distribution, predict maintenance needs, and respond to issues faster. For example, we noticed a transformer’s temperature rising during a heatwave and rerouted power to it—preventing overheating without any service disruption.

Of course, we faced challenges. The sheer volume of data from the smart sensors was overwhelming at first—we had to invest in data analytics tools and train our team to interpret the insights. Cybersecurity was another concern: with more connectivity came more risk, so we implemented end-to-end encryption and regular security audits to protect the network.

Looking ahead, I’m excited about AI-driven predictive maintenance. We’re developing algorithms that can analyze sensor data to forecast failures weeks in advance—this will let us replace components before they fail, eliminating unplanned outages and safety risks.

Self-healing transformers are another promising trend. These units use advanced materials that can repair minor insulation damage automatically, without human intervention. While still in the experimental stage, this technology could revolutionize transformer safety by reducing the need for manual repairs.

Cybersecurity will remain a top priority as transformers become more connected. We’re exploring isolated network architectures and AI-powered threat detection systems to keep our transformers safe from cyberattacks.

Conclusion

Pad mounted transformer safety is the backbone of reliable power distribution—protecting communities, workers, and critical infrastructure. By adopting best-in-class practices across installation, operation, maintenance, and emergency management, along with integrating cutting-edge technologies, we can build power systems that are safer, more efficient, and more sustainable.

From strategic site selection and robust grounding to intelligent monitoring and community engagement, every step plays a role in mitigating risks. As technology evolves, the future of transformer safety looks brighter—with innovations that let us predict issues before they occur, respond faster to emergencies, and minimize environmental impact.

At the end of the day, pad mounted transformer safety is about more than compliance—it’s about building trust with the communities we serve. By prioritizing safety in every aspect of our work, we ensure that these essential power hubs continue to deliver reliable energy while keeping people safe.