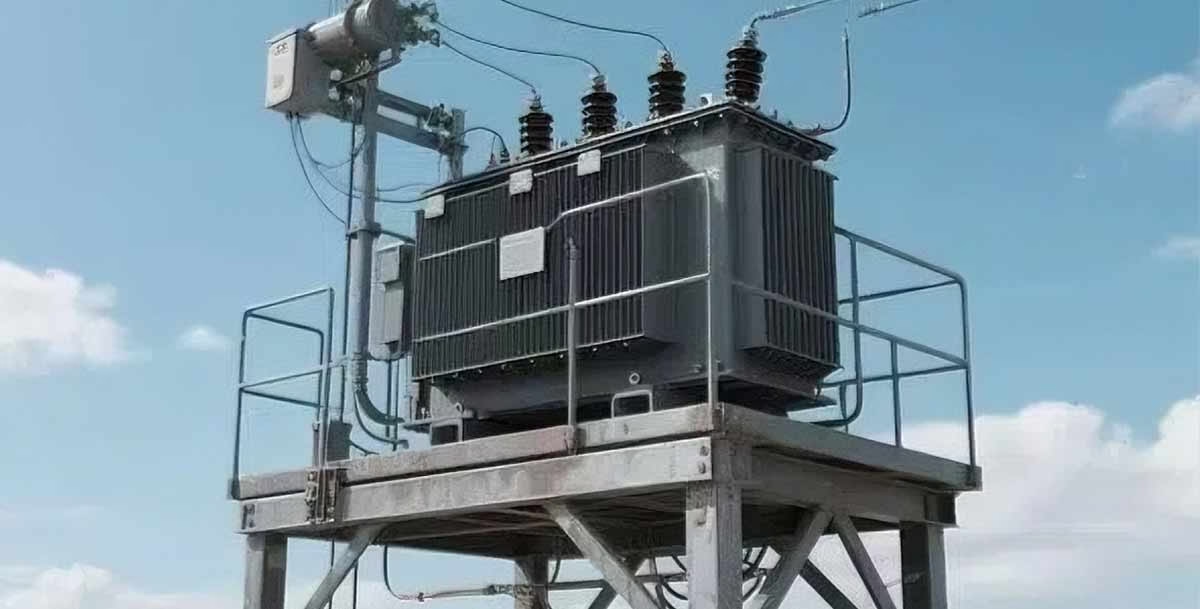

Oil immersed transformers operate based on electromagnetic induction, with transformer oil serving dual critical roles as an insulator and thermal management medium. By submerging the core and windings in specially formulated oil, these transformers achieve efficient voltage conversion while effectively dissipating heat—making them indispensable for high-power applications across electrical grids, industrial facilities, and infrastructure projects.

In my two decades of engineering and field experience with power systems, oil immersed transformers have consistently proven to be the backbone of reliable electricity distribution. They operate quietly behind the scenes, ensuring voltage levels are precisely calibrated for residential, commercial, and industrial use. Let’s explore the engineering ingenuity, key components, and operational dynamics that make these machines so essential.

Contents

hide

Electromagnetic Induction: The Fundamental Mechanism Behind Oil Immersed Transformers

Most of us encountered basic magnetism experiments in school, but the application of electromagnetic induction in transformers is what powers modern societies. How does this scientific principle translate into practical voltage transformation?

Electromagnetic induction is the cornerstone of oil immersed transformer operation. When alternating current (AC) flows through the primary winding, it generates a dynamic magnetic field within the transformer’s core. This fluctuating field induces an electromotive force (EMF) in the secondary winding, enabling the conversion of input voltage to the required output level. Transformer oil surrounds these components, ensuring electrical isolation and thermal stability throughout the process.

The Primary Winding: Initiating the Magnetic Cycle

The primary winding acts as the entry point for electrical energy, with three key functions:

- Accepting alternating current (typically from a power grid or generator) that reverses direction 50–60 times per second.

- Generating a magnetic field proportional to the current flow and number of winding turns.

- Magnetizing the transformer core to concentrate and direct magnetic flux efficiently.

Early in my career, I led a substation upgrade project where we reconfigured the primary winding of a 110kV transformer. Precise calculation of turn count was critical—even a 1% deviation would have compromised efficiency or caused overheating. This experience highlighted how the primary winding’s design directly impacts overall transformer performance.

The Core: Directing Magnetic Flux

The core serves as a “magnetic highway,” guiding flux between windings while minimizing energy losses. Common core materials and their advantages include:

| Core Material | Key Benefits | Typical Applications |

|---|---|---|

| Laminated Silicon Steel | Reduces eddy current losses; cost-effective | Utility-scale power transformers |

| Ferrite | High magnetic permeability at high frequencies | Electronic and low-power transformers |

| Amorphous Metal | Ultra-low core losses (30–50% less than silicon steel) | High-efficiency distribution transformers |

I once visited a manufacturing facility testing amorphous metal cores for a renewable energy project. The reduction in no-load losses was striking—over the transformer’s 30-year lifespan, this translates to hundreds of thousands of dollars in energy savings for the end user.

The Secondary Winding: Delivering Tailored Voltage

The secondary winding converts magnetic energy back to electrical energy, with three critical attributes:

- Induced voltage determined by the core’s magnetic flux and the winding’s turn count.

- Turn ratio (primary to secondary) that dictates voltage step-up or step-down (e.g., 132kV to 11kV for distribution).

- Connection points for linking to the load (industrial machinery, residential grids, etc.).

In a recent project for a chemical plant, we designed a transformer to step down 33kV to 400V. The turn ratio (82.5:1) was calibrated to account for voltage drops in the plant’s wiring, ensuring stable power delivery to sensitive equipment. This precision underscores why secondary winding design must align with specific application requirements.

Transformer Oil: The Unsung Hero of Insulation and Cooling

What makes transformer oil so critical to oil immersed transformer performance? It’s far more than a filling material—its dual role as insulator and coolant enables these machines to handle high voltages and power loads reliably.

Transformer oil performs two non-negotiable functions: electrical insulation and thermal dissipation. As an insulator, it prevents arcing between conductive components (windings, core, tank) by maintaining high dielectric strength. As a coolant, it absorbs heat from the core and windings, circulates to cooling surfaces (radiators, fans), and releases heat into the environment. This combination is what allows oil immersed transformers to operate at ratings from kVA to MVA without overheating or electrical breakdown.

Electrical Insulation: Safeguarding Against Discharges

Transformer oil’s insulating properties are critical for operational safety:

- Dielectric Strength: Resists electrical breakdown even at high voltages (typically 25–35 kV/mm for new oil).

- Gap Filling: Seeps into microscopic spaces between windings and core, eliminating air pockets that could cause arcing.

- Moisture Resistance: Repels water (a major insulator degrader) to protect sensitive components from corrosion and breakdown.

I once troubleshooted a 22kV transformer experiencing partial discharges. Oil analysis revealed moisture contamination (exceeding 30 ppm), which had reduced dielectric strength by 40%. After vacuum dehydrating the oil and replacing degraded seals, the transformer returned to full operational capacity—avoiding a costly replacement.

Thermal Dissipation: Managing Operational Heat

Effective cooling ensures transformers operate within safe temperature limits. Common cooling systems include:

| Cooling Method | Description | Ideal Applications |

|---|---|---|

| ONAN (Oil Natural, Air Natural) | Oil circulates via natural convection; air cools radiators passively | Small transformers (≤5 MVA) |

| ONAF (Oil Natural, Air Forced) | Natural oil circulation; fans boost air flow over radiators | Medium transformers (5–50 MVA) |

| OFAF (Oil Forced, Air Forced) | Pumps circulate oil; fans cool radiators actively | Large power transformers (>50 MVA) |

For a 200MVA transformer installed in a desert climate, we specified an OFAF system with variable-speed fans. This design reduced operating temperatures by 22°C compared to ONAN cooling, ensuring reliability even during 45°C summer days.

Oil Quality Maintenance: Preserving Performance

Transformer oil’s effectiveness degrades over time due to oxidation, contamination, and thermal stress. Key maintenance practices include:

- Routine Testing: Measuring dielectric strength, acidity (total acid number, TAN), and moisture content quarterly.

- Filtration: Removing particles and moisture via high-efficiency filters to extend oil life.

- Regeneration/Replacement: Reclaiming degraded oil via vacuum processing or replacing it after 15–20 years (depending on usage).

I helped implement an oil testing program for a utility company with 80+ transformers. Within six months, we identified four units with abnormal acidity levels—proactive oil regeneration saved the utility $200k in potential downtime and replacement costs.

Anatomy of an Oil Immersed Transformer: Key Components Working in Harmony

Beyond their robust exterior, oil immersed transformers are precision assemblies of components, each playing a vital role in performance and reliability. Understanding these parts helps explain how transformers deliver consistent voltage transformation.

An oil immersed transformer’s core components include the magnetic core, primary/secondary windings, oil-filled tank, bushings, cooling system, and control accessories. These elements work in tandem to convert voltage, manage heat, and ensure safe operation. Let’s break down their functions and design considerations.

The Core and Windings: The Transformative Heart

These components are the “engine” of the transformer, responsible for voltage conversion:

- Core: Typically constructed from stacked laminated steel to minimize eddy current losses. Core size depends on power rating—larger cores handle higher flux densities.

- Primary Winding: Wound with insulated copper or aluminum conductors, sized to withstand input voltage and current.

- Secondary Winding: Configured with a turn count matching the desired output voltage, often wound concentrically with the primary winding for efficient flux coupling.

I led the design of a custom transformer for a wind farm, where variable wind speeds required a flexible core and winding configuration. We used a stepped core design (to reduce flux leakage) and double-layer windings (for better heat distribution), ensuring the transformer adapted to fluctuating input power from 500kW to 2MW.

The Tank and Oil System: Containment and Cooling

The tank and associated components house and protect internal parts while facilitating heat transfer:

| Component | Function | Design Considerations |

|---|---|---|

| Main Tank | Encloses core, windings, and transformer oil | Welded steel construction; leak-proof seals; thermal expansion allowance |

| Transformer Oil | Insulates internal components; transfers heat | High dielectric strength; low viscosity (for cold climates); oxidation resistance |

| Expansion Tank (Conservator) | Accommodates oil volume changes due to temperature fluctuations | Connected to the main tank via a pipeline; equipped with a breather to prevent moisture ingress |

During the installation of a 66kV transformer in a coastal area, we specified a corrosion-resistant tank (with a zinc coating) and a sealed conservator (to protect against saltwater moisture). These design choices extended the transformer’s expected lifespan from 25 to 35 years.

Bushings and Control Accessories: Connectivity and Monitoring

These components enable safe external connections and real-time performance tracking:

- Bushings: Insulated sleeves that allow high-voltage conductors to enter/exit the tank without electrical leakage. Composite bushings (replacing traditional porcelain) offer lighter weight and better explosion resistance.

- Tap Changer: Adjusts the number of winding turns to fine-tune output voltage (critical for compensating for grid voltage fluctuations). On-load tap changers (OLTCs) allow adjustment without shutting down the transformer.

- Monitoring Devices: Temperature gauges (for oil and winding temperature), oil level indicators, pressure relief valves (to prevent tank rupture), and dissolved gas analysis (DGA) sensors.

In a substation upgrade project, we replaced old porcelain bushings with silicone rubber composite bushings on 132kV transformers. The new bushings reduced maintenance requirements by 60% and eliminated the risk of porcelain breakage— a common issue in areas prone to high winds.

Heat Management and Electrical Insulation: How Oil Elevates Transformer Performance

High-power transformers generate significant heat during operation—without effective thermal management, components would degrade rapidly. At the same time, electrical insulation is non-negotiable for preventing short circuits and ensuring safety. How does transformer oil excel at both tasks?

Transformer oil’s unique properties make it the ideal solution for dual-purpose heat management and electrical insulation. It efficiently absorbs heat from the core and windings (via convection or forced circulation) and transfers it to cooling surfaces. Simultaneously, its high dielectric strength (resistance to electrical breakdown) prevents arcing between conductive parts. This synergy allows oil immersed transformers to operate at voltages up to 765kV and power ratings exceeding 1000MVA while maintaining safe operating temperatures (typically ≤95°C for oil).

Heat Transfer Mechanisms: Keeping Components Cool

Transformer oil uses two primary circulation methods to dissipate heat:

- Natural Convection: As oil absorbs heat from the core and windings, it becomes less dense and rises to the top of the tank. Cooler, denser oil sinks to the bottom, creating a continuous circulation loop.

- Forced Circulation: In large transformers, pumps circulate oil through radiators or heat exchangers, accelerating heat transfer. This method is up to 3x more efficient than natural convection.

- External Radiators: Finned steel panels attached to the tank increase surface area, allowing heat to dissipate into the surrounding air (or water, for liquid-cooled systems).

I worked on optimizing the cooling system of a 500MVA power transformer for a utility company. By redesigning the radiator fin spacing (from 20mm to 15mm) and adding variable-speed circulation pumps, we reduced the transformer’s operating temperature by 18°C. This improvement cut energy losses by 12% and extended the winding insulation life by 50%.

Insulation Properties: Preventing Electrical Breakdown

Transformer oil’s insulation capabilities are defined by three key characteristics:

| Property | Function | Why It Matters |

|---|---|---|

| High Dielectric Strength | Resists electrical breakdown under voltage stress | Enables compact winding design (reducing transformer size and cost) |

| Optimal Viscosity | Flows easily to fill micro-gaps between components | Prevents air pockets (which cause partial discharges) and ensures uniform cooling |

| Chemical Stability | Maintains properties over time (resists oxidation and degradation) | Ensures long-term reliability without frequent oil replacement |

For a transformer operating in a cold region (temperatures as low as -30°C), we selected a low-viscosity oil (ISO VG 22) that remained fluid even in freezing conditions. This ensured consistent insulation and circulation—critical for preventing cold-start failures.

Proactive Monitoring: Ensuring Oil Performance

To maintain optimal heat management and insulation, real-time monitoring is essential:

- Oil Temperature Monitoring: Tracks oil temperature to detect overheating (a sign of winding damage or cooling system failure).

- Dissolved Gas Analysis (DGA): Measures gases (e.g., methane, ethane, acetylene) produced by internal faults (e.g., arcing, overheating). Online DGA systems provide early warning of potential failures.

- Oil Quality Testing: Regular analysis of dielectric strength, acidity, and moisture content to identify degradation before it impacts performance.

I implemented an online DGA monitoring system for a critical 220kV transformer at a data center. The system detected a small winding hot spot (via elevated ethylene levels) three months before it would have caused a failure. Planned maintenance (rewinding a section of the coil) avoided a 72-hour data center outage—saving the client $1.2M in downtime costs.

Maintenance and Longevity: Maximizing Transformer Reliability

Oil immersed transformers are significant capital investments—extending their lifespan and ensuring optimal performance requires proactive maintenance. By implementing a structured maintenance program, operators can avoid costly failures, reduce downtime, and maximize return on investment.

Effective maintenance of oil immersed transformers focuses on three core areas: oil quality management, electrical component testing, and cooling system upkeep. These activities not only extend the transformer’s service life (from 25 to 40+ years) but also ensure it operates at peak efficiency, minimizing energy losses and environmental impact.

Oil Quality Management: The Foundation of Longevity

Transformer oil is often called the “lifeblood” of the transformer—maintaining its quality is non-negotiable:

- Dielectric Strength Test: Measures the oil’s ability to resist electrical breakdown (conducted quarterly). Minimum acceptable values vary by application but typically exceed 25 kV/mm.

- Acidity Test (TAN): Tracks oil degradation (conducted semi-annually). A TAN value exceeding 0.2 mg KOH/g indicates the need for oil regeneration or replacement.

- Moisture Content Analysis: Ensures moisture levels remain below 20 ppm (conducted quarterly). Excess moisture reduces dielectric strength and accelerates corrosion.

I collaborated with a manufacturing plant to develop an oil maintenance program for their 10 transformers. By implementing quarterly testing and annual filtration, we reduced oil replacement costs by 70% and extended the average transformer lifespan by 10 years.

Electrical Component Testing: Ensuring Internal Health

Regular electrical testing identifies hidden issues (e.g., winding damage, core faults) before they escalate:

| Test | Purpose | Recommended Frequency |

|---|---|---|

| Winding Resistance Test | Detects loose connections, broken conductors, or winding damage | Annually |

| Turn Ratio Test | Verifies the transformer’s voltage conversion accuracy | Every 3–5 years (or after a fault) |

| Insulation Resistance Test | Measures the integrity of winding insulation (using a megohmmeter) | Annually |

| Core Loss Test | Identifies core damage or excessive eddy current losses | Every 5–7 years |

During a routine maintenance check, we discovered a 5% increase in winding resistance in a 11kV transformer. Further inspection revealed a loose connection in the secondary winding—repairing it prevented a potential short circuit that could have destroyed the transformer.

Cooling System Maintenance: Sustaining Thermal Performance

The cooling system is critical for preventing overheating—regular upkeep ensures it operates efficiently:

- Radiator Cleaning: Removes dust, debris, and corrosion from radiator fins (semi-annually) to maintain heat dissipation.

- Fan and Pump Inspection: Checks for mechanical wear, lubrication needs, and electrical faults in forced-cooling systems (quarterly).

- Oil Level Monitoring: Ensures oil levels remain within the recommended range (weekly, or via automated sensors). Low oil levels expose windings to air, increasing the risk of insulation breakdown.

For a substation with 15 large transformers, we designed a preventive maintenance schedule for cooling systems. By cleaning radiators twice a year and replacing fan motors every 8 years, we reduced cooling-related failures by 85% and improved average transformer efficiency by 4%.

Conclusion

Oil immersed transformers are the workhorses of modern power systems, leveraging electromagnetic induction and transformer oil’s dual insulation/cooling properties to deliver reliable voltage transformation. Their robust design—featuring precision-engineered cores, windings, tanks, and accessories—enables them to handle high voltages and power loads in diverse applications, from utility grids to industrial facilities.

Understanding their operational principles, key components, and maintenance needs is critical for maximizing performance and longevity. By prioritizing oil quality management, electrical testing, and cooling system upkeep, operators can ensure these transformers deliver decades of efficient, safe service—supporting the stability of electrical infrastructure worldwide.

As power demands grow and renewable energy integration expands, oil immersed transformers will remain essential for bridging the gap between power generation and end users—proving that even the most “unsung” components are the backbone of a connected world.