How Pad Mounted Transformers Work: The Science Powering Your Street’s Electricity

The Voltage Transformation Process

- High-Voltage Input

Electricity flows into the transformer from buried power lines, typically carrying voltages ranging from 4,000 to 34,500 volts—levels far too high for direct residential use.

- Electromagnetic Induction

The incoming high-voltage current passes through primary coils wrapped around a laminated steel core. This current creates a constantly changing magnetic field, which in turn induces an electric current in adjacent secondary coils. The ratio of turns between primary and secondary coils dictates the exact voltage reduction rate.

- Low-Voltage Output

The induced current exits the secondary coils at a much lower voltage, usually the 120/240-volt standard that powers everything from your refrigerator to your smartphone charger.

Efficiency and Load Management Innovations

- Load Tap Changers: These critical components adjust the transformer’s voltage output in real time to match neighborhood demand, ensuring stable power delivery during morning and evening peak usage hours, as well as quieter off-peak periods.

- Advanced Cooling Systems: Most units rely on natural oil circulation to dissipate heat generated during operation. For high-capacity models serving commercial areas or densely populated neighborhoods, integrated fans provide additional cooling to prevent overheating.

- Smart Monitoring Sensors: Cutting-edge units are equipped with sensors that track core temperature, insulating oil levels, and electrical load. This data enables utility teams to identify potential issues before they escalate, minimizing downtime and extending the transformer’s service life.

Component Efficiency Breakdown

| Component | Core Function | Impact on Overall Efficiency |

|---|---|---|

| Laminated Steel Core | Creates a focused path for magnetic flux | Minimizes eddy current losses, boosting energy efficiency by up to 2-3% |

| Copper/Aluminum Windings | Facilitates voltage conversion via induction | Copper windings offer lower resistance, reducing energy waste compared to aluminum alternatives |

| Insulating Oil | Cools internal parts and prevents electrical arcing | Maintains optimal operating temperatures, extending component lifespan and preserving efficiency over time |

| Load Tap Changers | Regulates output voltage to match demand | Eliminates voltage fluctuations that can waste energy and damage sensitive electronics |

Key Components of Pad Mounted Transformers: What’s Inside That Green Enclosure

The Core and Windings: The Heart of Voltage Conversion

- Laminated Steel Core: Constructed from thin, stacked steel sheets, this component creates a concentrated path for magnetic flux. The laminated design is intentional: it minimizes eddy current losses, which would otherwise waste energy and reduce efficiency.

- Primary Windings: These coils receive the incoming high-voltage power from utility lines. Typically made of high-conductivity copper wire, the number of turns in the primary windings is carefully calibrated to set the voltage reduction ratio.

- Secondary Windings: Positioned adjacent to the primary windings, these coils produce the low-voltage output for residential use. They have fewer turns than the primary windings, and their copper construction ensures minimal energy loss during current transfer.

Insulating Oil: The Unsung Workhorse

- Electrical Insulation: It prevents arcing and short circuits between the high-voltage primary windings and low-voltage secondary windings, as well as between the coils and the transformer’s metal enclosure.

- Heat Dissipation: As the transformer operates, it generates heat—especially during peak demand. The oil absorbs this heat and circulates naturally, dissipating it through the transformer’s walls to keep internal components cool.

- Component Preservation: The oil creates a protective barrier that shields the steel core and copper windings from moisture and oxidation, significantly extending the transformer’s service life. For eco-conscious applications, modern models use vegetable-based insulating oils instead of traditional mineral oils, offering better fire safety and biodegradability.

Bushings and Terminals: The Connection to the Grid

- High-Voltage Bushings: These heavily insulated components connect the transformer’s primary windings to incoming high-voltage lines. Their robust insulation prevents flashovers, even in wet or humid conditions.

- Low-Voltage Bushings: Designed for easier access, these components link the secondary windings to the low-voltage distribution lines that feed power to homes and businesses.

Auxiliary Components: Safety and Monitoring Systems

- Pressure Relief Device: In the event of an internal fault (such as a short circuit) that causes pressure to spike, this device releases excess pressure to prevent the transformer enclosure from rupturing.

- Temperature Gauge: Monitors the temperature of the insulating oil and windings, alerting maintenance teams if temperatures rise to dangerous levels.

- Oil Level Indicator: Provides a clear visual of the oil level inside the enclosure, helping to identify leaks or losses before they impact performance.

- Tap Changer: Adjusts the number of active turns in the windings to fine-tune voltage output, ensuring stable power delivery even as demand fluctuates.

Component Maintenance Checklist

| Component | Core Function | Critical Maintenance Considerations |

|---|---|---|

| Laminated Steel Core | Magnetic flux path | Inspect for unusual vibrations or humming sounds that indicate misalignment |

| Copper Windings | Voltage conversion | Monitor for overheating, which can signal insulation degradation |

| Insulating Oil | Cooling and insulation | Conduct regular oil testing to check for contaminants or moisture buildup |

| Bushings | Power connection | Inspect for cracks, corrosion, or leakage that could compromise insulation |

| Pressure Relief Device | Safety protection | Test annually to ensure it activates correctly under pressure |

| Temperature Gauge | Performance monitoring | Verify accuracy periodically to avoid false readings |

Conclusion

More FAQ About Pad Mounted Transformer

Q: Where are pad mounted transformers typically installed?

A: Pad mounted transformers are commonly installed in street easements, residential subdivisions, commercial parking lots, industrial campuses, and near outdoor facilities like solar farms. They are ideal for areas with underground power distribution lines, as their ground-mounted and enclosed design avoids the need for overhead transformer poles. Installation locations must comply with local electrical codes, ensuring sufficient clearance from buildings, walkways, and flammable materials. In residential areas, they are often placed at the edge of properties to minimize visual impact while ensuring a convenient power supply to multiple households.

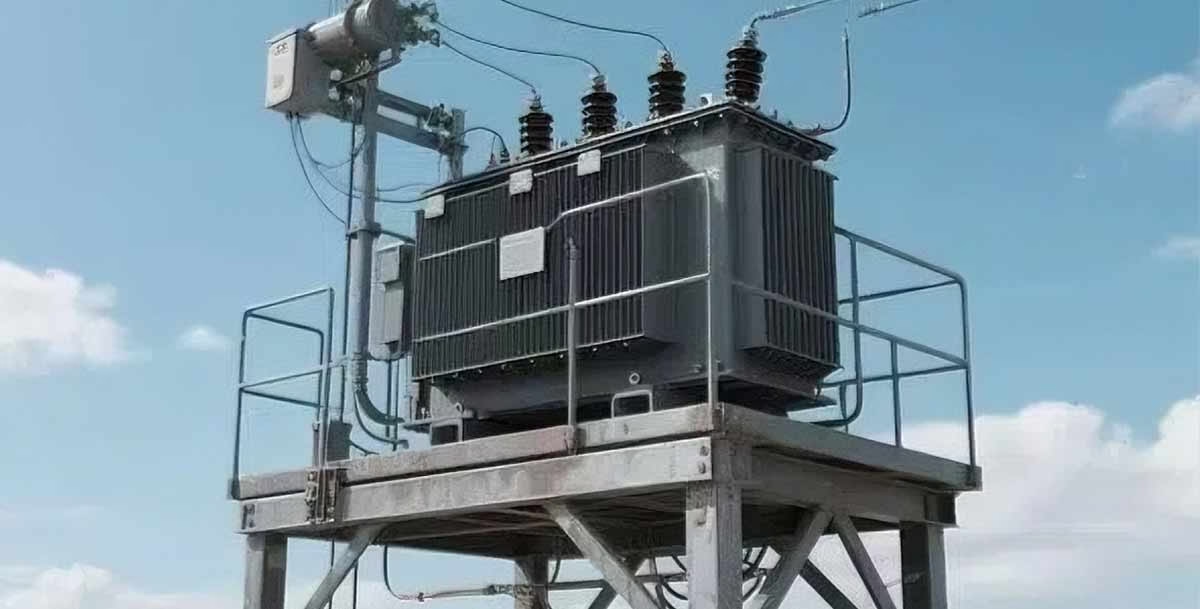

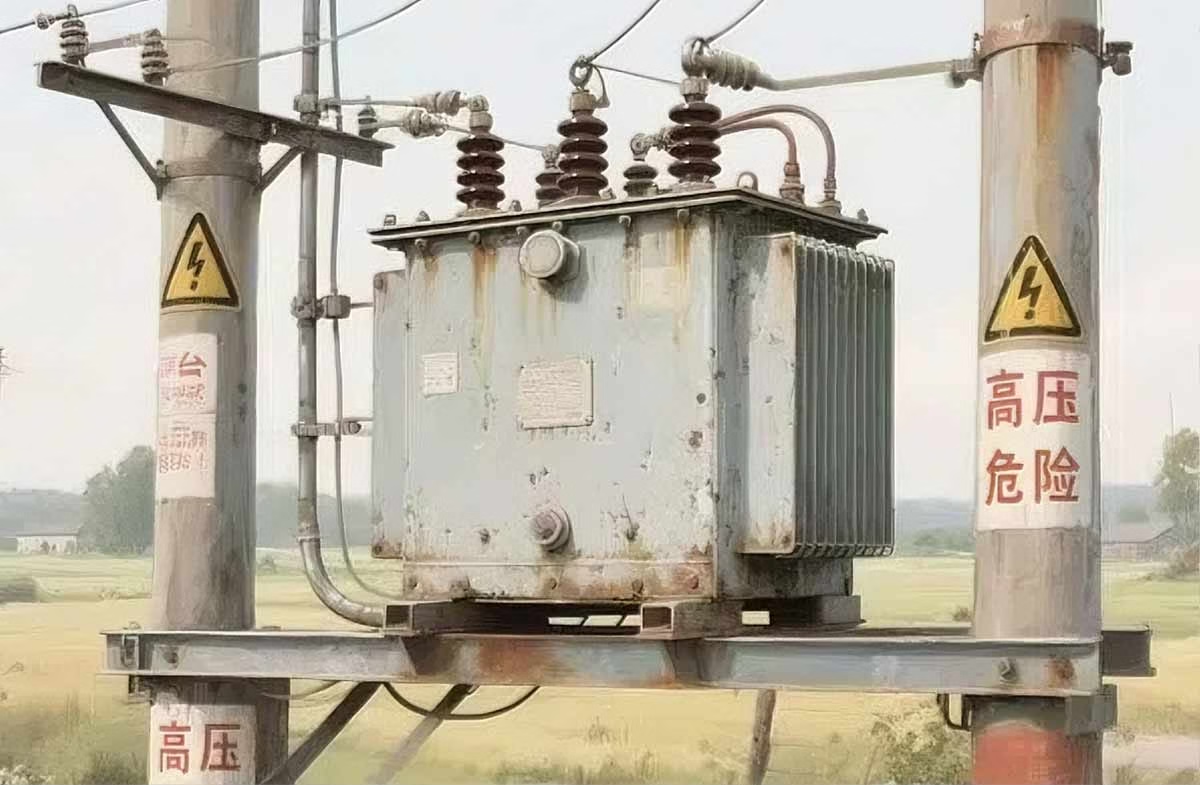

Q: What are the advantages of pad mounted transformers over pole-mounted transformers?

A: Compared to pole-mounted transformers, pad mounted transformers offer superior safety due to their enclosed cabinet, which prevents accidental contact with live components. They have a lower visual profile and are more aesthetically pleasing, making them suitable for urban and residential areas. Their design provides better protection against environmental damage (e.g., storms, wildlife) and reduces noise during operation. Additionally, pad mounted transformers can handle larger capacities and are easier to maintain, as technicians can access components without climbing poles. However, they require more ground space and higher initial installation costs for concrete pad construction.

Q: What are the common types of pad mounted transformers (oil-immersed vs. dry-type)?

A: Most traditional pad mounted transformers are oil-immersed, using insulating oil for cooling and insulation. They offer high thermal efficiency, large capacity, and lower cost, making them suitable for outdoor use in most climates. Dry-type pad mounted transformers, which use air or solid insulation materials (e.g., Nomex), are non-flammable and ideal for areas with strict fire safety requirements, such as near buildings, hospitals, or chemical facilities. Dry-type models require less maintenance but have higher upfront costs and smaller capacity limits. The selection depends on environmental conditions, fire codes, and budget constraints.

Q: What key parameters should be considered when selecting a pad mounted transformer?

A: Key selection parameters include rated capacity (kVA), primary and secondary voltage levels, insulation type (oil-immersed or dry-type), cooling method, load type, and environmental conditions. Rated capacity should be sized to meet current load demands with a 10-20% margin for future growth, calculated as kVA = total load power (kW) ÷ power factor (typically 0.8-0.9). Voltage levels must match the utility grid (e.g., 10kV primary, 0.4kV secondary) and end-user equipment. Additionally, factors like efficiency rating, noise level (compliant with NEMA TR 1), and protection level (IP rating) should be considered to ensure reliable and cost-effective operation.

Q: What are the common faults of pad mounted transformers and how to handle them?

A: Common faults include oil leaks (oil-immersed types), winding short circuits or open circuits, core grounding issues, and tap changer malfunctions. Oil leaks require immediate repair of seals or gaskets and refilling with appropriate insulating oil. winding faults, indicated by abnormal temperature rise or voltage fluctuations, require off-the-line testing (e.g., DC resistance, oil chromatography) and repair (e.g., rewinding or insulating reinforcement). Core grounding issues, which cause increased loss and overheating, can be resolved by removing metal debris or replacing insulation. Tap changer problems, such as contact oxidation, require cleaning or replacement. All faults should be addressed by qualified technicians to avoid safety hazards or equipment damage.

Q: What is the overload capacity of a pad mounted transformer?

A: Pad mounted transformers are designed to handle short-term overloads, typically 120% of rated capacity for 2 hours or 150% for 1 hour, depending on the model and cooling method. Oil-immersed models have better overload capacity due to the heat-dissipating properties of insulating oil, while dry-type models have more limited overload capability. Long-term overload should be avoided, as it causes excessive temperature rise, accelerates insulation aging, and reduces lifespan. Overload capacity is specified by manufacturers in compliance with IEEE standards, and operators should monitor load levels to ensure they stay within safe limits.

Q: How to ensure the safety of pad mounted transformers in public areas?

A: Safety in public areas is ensured through several design and operational measures: hermetically sealed steel cabinets that prevent access to live components; grounding of the cabinet to eliminate electric shock risks; clear safety labels (compliant with NEMA 260) indicating high-voltage hazards; and installation of protective devices (fuses, circuit breakers) that trip in case of faults. Additionally, installation locations are selected to minimize pedestrian contact, with sufficient clearance from walkways and play areas. Regular inspections for cabinet damage or tampering also help maintain safety in public environments.

Q: What factors affect the cost of a pad mounted transformer?

A: Key cost factors include rated capacity (larger capacity = higher cost), insulation type (dry-type models are 20-30% more expensive than oil-immersed), material quality (copper windings vs. aluminum windings), efficiency rating (high-efficiency models have higher upfront costs), and customization (e.g., special voltage levels, weatherproofing for harsh climates). Installation costs, including concrete pad construction, wiring, and testing, also contribute significantly. Oil-immersed transformers have lower initial costs but higher long-term maintenance costs (oil testing, leak repairs), while dry-type models have lower maintenance costs but higher upfront investment.

Q: How to detect and prevent oil leaks in oil-immersed pad mounted transformers?

A: Oil leaks can be detected through regular visual inspections for oil stains around the cabinet, gaskets, and bushings. Advanced methods include using oil level sensors and pressure monitoring systems that trigger alarms when leaks occur. Prevention measures include using high-quality gaskets and seals, ensuring proper installation torque for connections, and avoiding physical damage to the cabinet. Regular oil sampling and testing also help maintain oil quality, reducing the risk of degradation that can lead to seal failure. In cold climates, heating systems may be installed to prevent oil viscosity changes that can stress seals.