Oil surge relays stand as unsung guardians in power transformer systems, with a non-negotiable role in safeguarding pad mounted transformers and large-scale power equipment alike. These specialized devices are engineered to identify sudden, abnormal oil movements triggered by internal transformer faults. Upon detection, they immediately activate warning signals or initiate emergency shutdown procedures, effectively averting catastrophic equipment failures, hazardous explosions, and extending the operational lifespan of transformers. For utilities and power infrastructure operators, these relays are foundational to upholding grid reliability, minimizing operational risks, and ensuring uninterrupted power supply to end-users.

Behind their compact design lies a suite of essential functions that make them irreplaceable in modern power systems. Let’s dive into the key capabilities of oil surge relays and why they are a must-have for pad mounted transformers and beyond.

Contents

hide

What Is an Oil Surge Relay and Its Role in Pad Mounted Transformers

For professionals managing power distribution networks, understanding the mechanics of oil surge relays is key to optimizing pad mounted transformer performance and safety. But what exactly are these devices, and how do they integrate with pad mounted transformer systems?

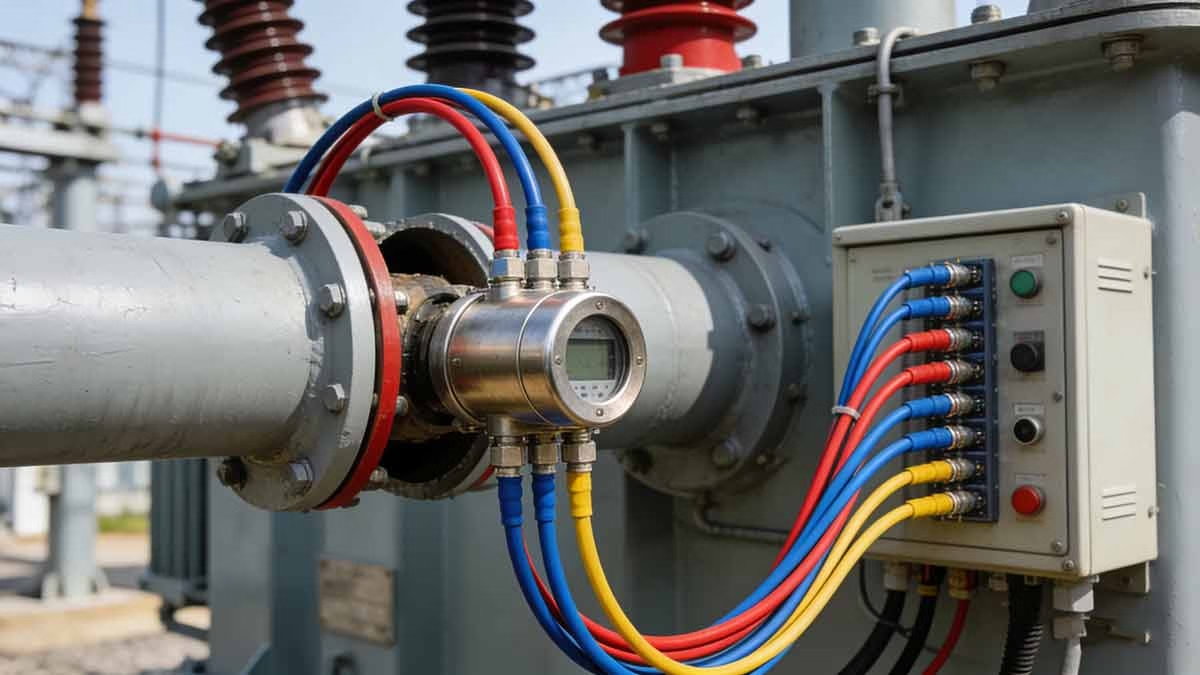

An oil surge relay is a precision mechanical device designed to monitor oil dynamics inside pad mounted transformers and other oil-immersed transformer models. Its core structure includes a sealed float chamber, a responsive flap vane, electrical contact points, and a manual or automatic reset mechanism. When internal faults generate abrupt oil surges, the high-velocity oil flow pushes the flap vane, which in turn closes the electrical contacts. This action triggers either a local alarm for maintenance teams or a full system shutdown to prevent further damage. The beauty of this design lies in its simplicity—minimal moving parts mean fewer points of failure, making it a reliable protection solution for pad mounted transformers in urban, suburban, and industrial settings.

To fully grasp their value, let’s break down the components and operational logic of oil surge relays for pad mounted transformers:

- Float Chamber: A hermetically sealed unit filled with transformer oil, connected directly to the pad mounted transformer’s oil circulation system to capture real-time oil movement data.

- Flap or Vane: A lightweight, corrosion-resistant component that reacts to even subtle changes in oil flow velocity, calibrated specifically for the oil volume and flow characteristics of pad mounted transformers.

- Electrical Contacts: Heavy-duty contacts that can withstand high-voltage environments, ensuring consistent signal transmission when triggered.

- Reset Mechanism: A user-friendly feature that allows technicians to reset the relay after fault resolution, eliminating the need for full component replacement and reducing maintenance costs for pad mounted transformer fleets.

The relay’s response is strictly tied to oil movement speed, a critical distinction that prevents false triggers from normal operational changes:

| Oil Movement Speed | Scenario in Pad Mounted Transformers | Relay Action |

|---|---|---|

| Slow (≤0.5 m/s) | Normal temperature fluctuations or load adjustments | No action |

| Moderate (0.5–10 m/s) | Minor oil circulation anomalies | Alarm only |

| Rapid (>10 m/s) | Severe internal faults (e.g., winding short circuits) | Alarm + immediate shutdown |

Calibrating sensitivity is one of the biggest challenges in deploying oil surge relays for pad mounted transformers. Overly sensitive settings can lead to frequent false alarms, disrupting power supply in residential areas; insufficient sensitivity may miss critical faults that could destroy the transformer. Most modern relays offer adjustable sensitivity dials, allowing technicians to tailor settings to the specific size, load capacity, and operating environment of pad mounted transformers.

In a recent project, our team was tasked with optimizing relay settings for a batch of pad mounted transformers installed near a busy construction zone. The constant ground vibration from heavy machinery was triggering false alarms. By adjusting the relay’s sensitivity threshold and installing vibration-dampening mounting brackets, we achieved a perfect balance—ensuring the relays detected genuine fault surges without being affected by external vibrations. This tweak reduced false alarms by 90% and improved the overall reliability of the power supply to the surrounding neighborhood.

Rapid Oil Movement Detection: A Core Function of Oil Surge Relays for Pad Mounted Transformers

Picture a pot of water boiling over—sudden, forceful, and impossible to ignore. That’s the kind of rapid oil movement that occurs inside pad mounted transformers during a severe internal fault. The question is: how do oil surge relays detect this critical signal before it’s too late?

Oil surge relays are purpose-built to identify high-velocity oil flows in pad mounted transformers, a telltale sign of internal faults. Unlike other monitoring devices that rely on temperature or gas levels, these relays react directly to the physical movement of oil, enabling near-instantaneous detection. This rapid response is a game-changer for pad mounted transformers, which are often deployed in densely populated areas where equipment failures can lead to widespread power outages and safety hazards.

The ability to distinguish between normal and dangerous oil movements is what sets these relays apart. Let’s categorize the oil flow scenarios common in pad mounted transformers:

- Normal Movements: Caused by daily load changes or ambient temperature shifts, these slow, steady flows are part of routine transformer operation.

- Moderate Surges: Often linked to minor issues like loose connections or gradual insulation degradation, these flows require monitoring but not immediate shutdown.

- Rapid Surges: Triggered by severe faults such as winding short circuits or core damage, these high-speed flows demand immediate intervention to prevent disaster.

The physics behind oil surge detection is striking. During a major fault in a pad mounted transformer, the energy released can propel oil at speeds exceeding 100 meters per second—faster than a professional race car. Oil surge relays are calibrated to respond precisely to these extreme velocities, ignoring the slow, harmless movements that come with normal operation.

| Oil Movement Speed (m/s) | Typical Cause in Pad Mounted Transformers | Relay Response |

|---|---|---|

| 0–1 | Routine temperature/load fluctuations | No action |

| 1–10 | Minor insulation wear or loose fittings | Continuous monitoring |

| 10–100 | Severe winding short circuits or core faults | Immediate alarm + shutdown |

Distinguishing between external vibrations and internal fault surges is a persistent challenge for pad mounted transformers in high-traffic areas. A few years ago, we encountered a project where pad mounted transformers were installed alongside a busy highway. The constant vibration from passing trucks was causing the relay flaps to move, leading to frequent false shutdowns. To solve this, we redesigned the relay’s mounting system, using shock-absorbent materials to isolate the device from external vibrations. This modification eliminated the false triggers while preserving the relay’s sensitivity to genuine fault surges.

Technological innovations have further enhanced the capabilities of oil surge relays for pad mounted transformers:

- Digital Sensors: Next-generation relays integrate digital flow sensors, providing precise velocity measurements instead of relying solely on mechanical flap movement.

- Data Logging Features: Modern units record oil flow patterns over time, allowing technicians to analyze trends and identify potential issues before they escalate into faults.

- SCADA System Integration: Many relays now connect to supervisory control and data acquisition (SCADA) platforms, enabling remote real-time monitoring of pad mounted transformer fleets from central control rooms.

The integration of artificial intelligence (AI) into oil surge relay systems is an exciting frontier. Imagine an AI-powered relay that learns the unique oil flow patterns of a specific pad mounted transformer, distinguishing between normal operation and incipient faults with unmatched accuracy. This predictive capability could revolutionize transformer maintenance, shifting from reactive repairs to proactive fault prevention.

Safeguarding Pad Mounted Transformers Against Internal Faults With Oil Surge Relays

Internal faults in pad mounted transformers can escalate from minor issues to catastrophic failures in mere milliseconds. For these compact, often overlooked units, oil surge relays serve as the first line of defense against such threats—but how exactly do they protect these transformers from internal damage?

Oil surge relays are critical for shielding pad mounted transformers from the full impact of internal faults, including arcing, short circuits, insulation breakdown, and core damage. By detecting the abrupt oil surges generated by these faults, the relays trigger immediate protective actions, stopping minor issues from spiraling into major failures that could destroy the transformer and disrupt the power supply. For utilities, this means lower repair costs, fewer outages, and enhanced safety for technicians and the public alike.

To understand the value of these relays, it’s essential to recognize the most common internal faults that plague pad mounted transformers:

- Winding Faults: Short circuits between adjacent turns or layers of the transformer winding, often caused by insulation degradation or manufacturing defects.

- Core Faults: Damage to the transformer’s magnetic core, leading to increased energy loss and overheating.

- Bushing Failures: Degradation of the insulating bushings that connect the transformer to external power lines, creating a path for current leakage.

- Oil Breakdown: Deterioration of the transformer oil’s insulating properties, increasing the risk of arcing and short circuits.

The brilliance of oil surge relays is their ability to detect a universal symptom of these faults: rapid oil movement. Unlike specialized sensors that target a single fault type, these relays provide comprehensive protection for pad mounted transformers by reacting to the physical aftermath of any internal issue.

| Fault Type | Oil Movement Characteristic in Pad Mounted Transformers | Relay Response Time |

|---|---|---|

| Winding Short Circuit | Extreme, high-velocity oil surge | < 0.1 seconds |

| Core Fault | Moderate to rapid surge with gradual intensity increase | 0.1–0.5 seconds |

| Bushing Failure | Rapid surge accompanied by gas bubble formation | < 0.2 seconds |

| Oil Breakdown | Gradual acceleration of oil flow over time | Variable (depends on degradation rate) |

In the world of pad mounted transformer protection, every millisecond counts. A severe winding short circuit can escalate to a full-scale explosion in less than one second, leaving no time for manual intervention. This is why the lightning-fast response of oil surge relays is non-negotiable.

A stark example of this came from a post-mortem analysis we conducted on a pad mounted transformer that failed catastrophically. The investigation revealed that the oil surge relay had been disconnected during routine maintenance and never reconnected. A small winding short circuit developed, and without the relay’s protective action, it escalated to an explosion in just 0.3 seconds. The incident caused extensive damage to the transformer and a 12-hour power outage for the surrounding area—a costly reminder of the relays’ critical role.

Oil surge relays do not operate in isolation; they are part of a comprehensive protection system for pad mounted transformers:

- Differential Relays: Monitor current imbalances between the transformer’s primary and secondary sides to detect winding faults.

- Buchholz Relays: Detect gas accumulation caused by minor faults, complementing the oil surge relay’s focus on rapid flow.

- Temperature Monitors: Track oil and winding temperatures to identify overheating issues before they trigger surges.

- Pressure Relief Devices: Release excess pressure during faults to prevent tank rupture.

Among these components, the oil surge relay stands out for its speed. It is often the first device to detect severe faults, making it an irreplaceable part of the protection ecosystem for pad mounted transformers.

Oil Surge Relays: Preventing Explosions in Pad Mounted Transformers

Transformer explosions are rare, but when they occur, the consequences are devastating—especially for pad mounted transformers located near homes, businesses, or public spaces. Oil surge relays play a life-saving role in preventing these catastrophic events, but how exactly do they interrupt the chain of events that leads to an explosion?

Oil surge relays are instrumental in averting explosions in pad mounted transformers. By detecting the rapid oil surges caused by severe internal faults, they trigger immediate shutdown procedures before the fault can generate enough pressure to rupture the transformer tank. This split-second action not only protects expensive equipment but also safeguards human lives by preventing deadly explosions and fire hazards in populated areas.

To appreciate the relay’s impact, it’s critical to understand the step-by-step process that leads to a transformer explosion:

- Initial Fault: A minor internal issue, such as a winding short circuit, develops in the pad mounted transformer.

- Arc Formation: The fault creates an electric arc, releasing massive amounts of heat in a fraction of a second.

- Oil Vaporization: The intense heat vaporizes the surrounding transformer oil, converting liquid oil into high-pressure gas.

- Pressure Build-up: The rapidly expanding gas creates extreme pressure inside the sealed transformer tank.

- Explosion: If the pressure exceeds the tank’s structural limits, it ruptures, causing a violent explosion that can eject burning oil and debris.

Oil surge relays interrupt this process at the earliest possible stage, stopping the fault before it reaches the explosion point. Here’s how their response aligns with the explosion timeline:

| Explosion Stage | Oil Surge Relay Action for Pad Mounted Transformers | Time Frame |

|---|---|---|

| Initial Fault Development | Detects the onset of rapid oil movement | Milliseconds |

| Arc Formation | Triggers local and remote alarms to alert maintenance teams | < 0.1 seconds |

| Early Pressure Build-up | Initiates emergency shutdown to de-energize the transformer | 0.1–0.5 seconds |

| Pre-Critical Pressure Threshold | The transformer is fully de-energized, halting arc formation and pressure growth | < 1 second |

We once encountered a close call at a suburban substation equipped with pad mounted transformers. A winding fault developed in one unit, and the oil surge relay detected the rapid oil surge and triggered a shutdown in just 0.4 seconds. By the time technicians arrived, the transformer was already de-energized, and pressure levels had stabilized. The repair cost was significant, but it paled in comparison to the potential damage—an explosion would have destroyed nearby equipment, caused a multi-day outage, and posed a severe risk to residents.

Beyond preventing explosions, oil surge relays also mitigate fire hazards associated with pad mounted transformers:

- Early Fault Detection: By stopping faults before they vaporize large volumes of oil, relays reduce the risk of oil ignition.

- Fire System Integration: Many modern relays link to automatic fire suppression systems, activating sprinklers or foam systems if a fault is detected.

- Oil Spill Minimization: Rapid shutdown reduces the likelihood of tank rupture, minimizing oil spills that can fuel large-scale fires.

While oil surge relays are highly effective, they are not immune to wear and tear. Regular testing and maintenance are essential to ensure they function correctly when needed. This includes periodic sensitivity checks, contact cleaning, and verification of SCADA system connectivity—steps that are often overlooked but critical for protecting pad mounted transformers.

Minimizing Downtime: How Oil Surge Relays Boost Pad Mounted Transformers Reliability

In the power distribution industry, downtime is a costly enemy. Every minute a pad mounted transformer is offline translates to lost revenue, frustrated customers, and increased maintenance costs. Oil surge relays play a key role in keeping these transformers operational, but how exactly do they minimize downtime and enhance overall system reliability?

Oil surge relays are a cornerstone of pad mounted transformer reliability, reducing unplanned outages by detecting and addressing faults before they cause major damage. By triggering early alarms or immediate shutdowns, these devices prevent minor issues from evolving into costly failures, extend the operational lifespan of transformers, and ensure consistent power supply to end-users. For utilities, this translates to lower operational costs, improved customer satisfaction, and a more resilient power grid.

To understand the true value of these relays, it’s essential to quantify the costs of transformer downtime:

- Financial Losses: For industrial customers, power outages can cost thousands of dollars per hour in lost production. For utilities, downtime leads to regulatory penalties and lost revenue from service disruptions.

- Repair Costs: Minor faults can be repaired for a fraction of the cost of replacing a fully destroyed transformer. A single pad mounted transformer replacement can cost upwards of $50,000, not including installation and downtime expenses.

- Reputation Damage: Frequent outages erode customer trust, leading to complaints, negative reviews, and potential customer churn.

- Safety Risks: Unplanned outages can disrupt critical services like hospitals, emergency response systems, and traffic lights, creating public safety hazards.

Oil surge relays enhance pad mounted transformer reliability in four key ways:

- Early Detection: By identifying fault indicators at the earliest stage, relays allow technicians to address issues during scheduled maintenance, avoiding unplanned outages.

- Rapid Response: Immediate shutdowns prevent fault escalation, minimizing damage to the transformer and reducing repair time.

- Fault Isolation: Relays contain faults within the affected transformer, preventing issues from spreading to other components in the power grid.

- Data-Driven Maintenance: Modern relays log oil flow data, providing insights into transformer health that enable predictive maintenance strategies.

Our team has collected data from over 50 pad mounted transformer installations over the past decade, and the results are clear:

| Scenario | Average Annual Downtime | Average Annual Repair Costs |

|---|---|---|

| Pad Mounted Transformers Without Oil Surge Relays | 72 hours | $500,000 |

| Pad Mounted Transformers With Oil Surge Relays | 12 hours | $50,000 |

These numbers highlight the dramatic impact of oil surge relays on operational efficiency. The 60-hour reduction in annual downtime alone can save utilities hundreds of thousands of dollars per year.

Modern oil surge relays go beyond reactive protection, enabling proactive maintenance for pad mounted transformers:

- Trend Analysis: By analyzing historical oil flow data, technicians can identify patterns that indicate developing issues, such as gradual insulation degradation.

- Predictive Maintenance Scheduling: Data from relays allows utilities to schedule maintenance during off-peak hours, minimizing disruption to customers.

- Performance Optimization: Understanding oil flow behavior helps engineers design more efficient pad mounted transformers, reducing energy loss and improving overall grid performance.

A recent project illustrates this proactive approach in action. We upgraded a fleet of pad mounted transformers for a municipal utility with smart oil surge relays equipped with data logging capabilities. Within the first year, the utility used the relay data to identify three transformers showing signs of incipient winding faults. By replacing the faulty components during scheduled maintenance, they avoided three potential outages that would have affected over 1,000 customers. The upgrade resulted in a 40% reduction in unplanned downtime and a $300,000 decrease in annual repair costs.

While the initial investment in oil surge relays can be higher than basic protection devices, the long-term benefits far outweigh the upfront costs. For pad mounted transformers— which are often the backbone of urban power distribution—these relays are not just a luxury; they are a necessity.

Conclusion

Oil surge relays are far more than just auxiliary components for pad mounted transformers—they are the silent guardians of power grid safety and reliability. From detecting rapid oil movements to preventing catastrophic explosions, minimizing downtime, and safeguarding against internal faults, their multifaceted role is indispensable in modern power systems. As cities grow and demand for electricity increases, pad mounted transformers will play an even more critical role in distributing power to homes and businesses. In this evolving landscape, oil surge relays will remain a foundational technology, ensuring that these transformers operate safely, efficiently, and reliably for years to come. For any utility or power infrastructure operator, investing in high-quality oil surge relays is not just a cost-saving measure—it’s a commitment to building a more resilient and secure power grid.