Mastering 3 phase pad mounted transformer installation hinges on four core pillars: strategic site preparation, meticulous handling, precise electrical connections, and comprehensive testing. Adhering to these standards empowers utility providers to deliver power that’s not just safe and efficient, but consistently reliable for communities and businesses alike.

Ever paused to wonder about the work behind those familiar green utility boxes dotting neighborhoods? Installing them is far more involved than simply placing equipment and connecting wires—every step demands expertise to ensure long-term performance.

In this guide, we’ll draw on real-world field experience to break down everything from site selection to final energization. Whether you’re a utility professional or simply curious about power infrastructure, you’ll gain actionable insights to ensure successful transformer deployment.

Contents

hide

From Delivery to Power-Up: A Step-by-Step Guide to 3 Phase Pad Mounted Transformer Installation

Installing 3 phase pad mounted transformers is a structured process that leaves no room for shortcuts. The journey from delivery to full operation encompasses site preparation, precision placement, electrical integration, oil management, and rigorous testing—each phase critical to avoiding costly downtime later.

Let’s unpack each stage with practical, field-proven steps:

Site Preparation: Building a Stable Foundation

The longevity of your transformer starts with the ground it sits on. Skipping proper site prep is one of the most common causes of premature equipment issues.

Core Actions:

- Geotechnical soil analysis and compaction verification

- Reinforced concrete pad construction (engineered for equipment weight)

- Underground conduit routing for cable protection

- Comprehensive grounding system installation (meets local electrical codes)

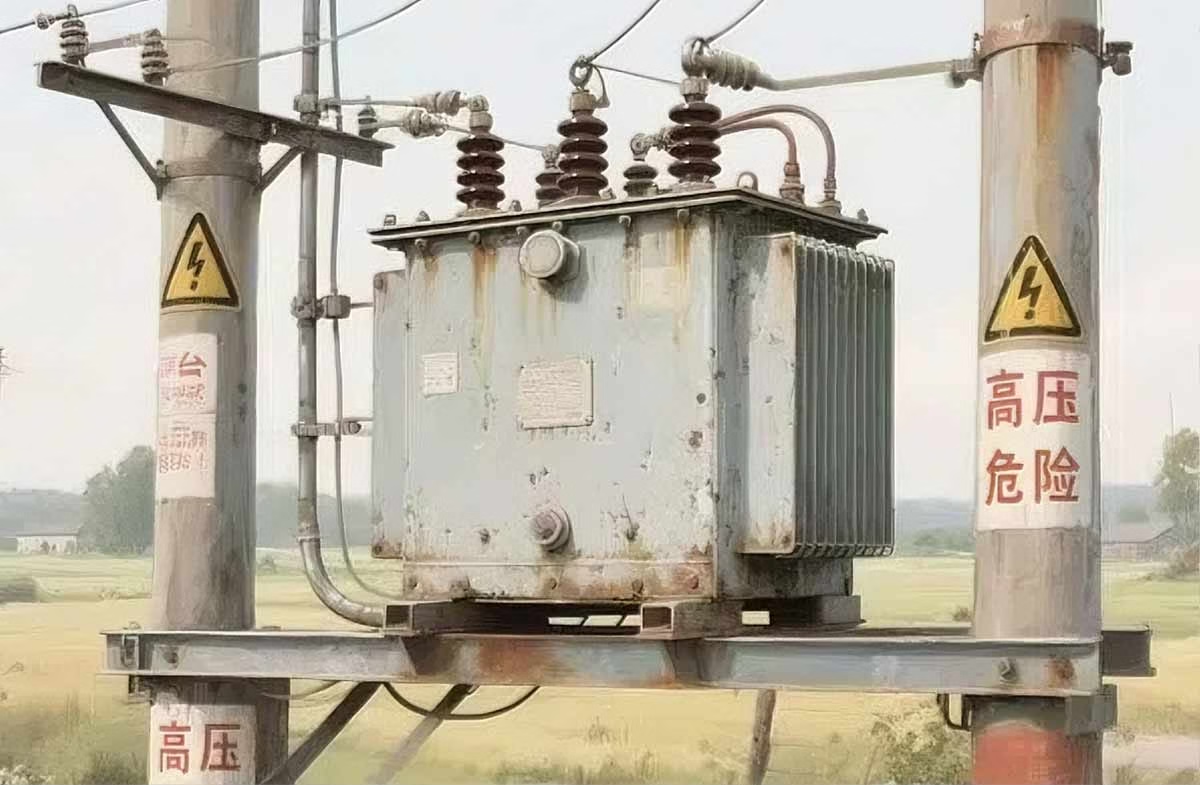

Transformer Placement: Precision in Heavy Lifting

Moving and positioning a pad mounted transformer requires careful coordination to prevent damage and ensure safety.

Key Considerations:

- Deployment of rated lifting equipment (matched to transformer weight/size)

- Laser-aligned positioning on the concrete pad

- Compliance with clearance requirements (for maintenance and ventilation)

- Secure anchoring to resist environmental stressors (wind, seismic activity)

Electrical Connections: Integrating with the Grid

This phase is where the transformer becomes part of the live power network—accuracy here is non-negotiable.

Connection Protocol:

- High-voltage cable termination (using manufacturer-specified techniques)

- Low-voltage distribution connections (verified for phase alignment)

- Neutral and ground conductor bonding (meets grid safety standards)

- Surge arrester installation (protects against voltage spikes)

Oil Filling: Safeguarding Insulation and Cooling

For oil-filled transformers, proper fluid management is critical for insulation and heat dissipation.

Step-by-Step Process:

- Vacuum evacuation to eliminate moisture and air pockets

- Controlled oil filling (at specified temperature and flow rate)

- Oil level calibration and pressure testing

- Post-filling dielectric strength analysis (ensures oil purity)

Final Testing: Verifying Performance Before Energization

No installation is complete without comprehensive testing to confirm everything operates as intended.

Critical Tests:

- Insulation resistance measurements (using megohmmeter)

- Turns ratio verification (ensures correct voltage conversion)

- Winding resistance testing (identifies connection issues)

- Accessory functionality checks (cooling systems, pressure relief valves)

| Installation Phase | Key Considerations | Typical Missteps |

|---|---|---|

| Site Preparation | Soil stability, drainage efficiency | Inadequate compaction, poor runoff planning |

| Transformer Placement | Lifting capacity, alignment accuracy | Equipment damage during transit, misalignment on pad |

| Electrical Connections | Termination quality, grounding integrity | Loose connections, incorrect phase matching |

| Oil Filling | Moisture removal, contamination prevention | Air entrapment, use of non-specified oil |

| Final Testing | Comprehensive protocol adherence | Skipping critical tests, misinterpreting results |

I recall a particularly demanding installation in a high-density residential district. Space was extremely limited, requiring coordination with city traffic departments, utility companies, and local businesses to manage access and safety. The site posed unique challenges due to existing underground utilities—we had to modify our excavation plan and redesign the concrete pad to avoid conflicts.

During placement, we encountered an unexpected hurdle: our initial crane lacked the vertical reach to clear nearby power lines. We quickly sourced a telescopic crane with extended boom capacity, which delayed our timeline by half a day but was essential to avoiding a safety incident.

Electrical connections, while technically straightforward, demanded extra diligence. We implemented a dual-verification process—each connection was checked by two technicians—and used thermal imaging to identify potential hotspots before energization. This extra step paid off when we detected a slightly loose termination that would have caused overheating under load.

Oil filling required meticulous attention to detail. We used a vacuum system to evacuate the transformer for 24 hours (longer than the standard 12) due to high humidity levels that day. After filling, we sent oil samples to an independent lab for analysis—and caught a batch with trace contaminants that would have compromised insulation over time. Replacing the oil before energization saved us from a potential failure within the first year of operation.

The testing phase is where many teams cut corners, but we insisted on a full suite of diagnostics. Our efforts uncovered a minor bushing insulation issue that would have gone unnoticed with basic testing. The fix was simple—a quick replacement on-site—but it prevented what could have been a catastrophic failure after commissioning.

This methodical approach, while time-intensive, ensures that every transformer we install operates safely and reliably for decades. The extra hours invested in proper installation translate to reduced maintenance costs, fewer outages, and greater trust from the communities we serve.

Safety First: Non-Negotiable Safety Measures for Urban 3 Phase Transformer Installations

Installing large electrical equipment in busy urban environments comes with unique risks—protecting workers, the public, and property must be the top priority at every stage.

The foundation of safe urban transformer installation lies in robust site security, strategic traffic management, strict electrical protocols, and proactive community communication. These measures create a controlled environment that minimizes hazards while keeping daily life moving.

Let’s explore the critical safety components:

Site Security: Securing the Work Zone

Urban worksites attract curious onlookers, making perimeter security essential to preventing accidents.

Security Protocols:

- High-visibility, anti-climb fencing (minimum 6-foot height)

- Clear warning signage (in multiple languages, where applicable)

- 24/7 security personnel for high-traffic or overnight projects

- LED lighting and surveillance cameras for after-hours monitoring

Traffic Management: Minimizing Disruptions

Urban installations often impact roadways and pedestrian traffic—careful planning keeps both workers and commuters safe.

Traffic Strategies:

- Pre-approval from local transportation authorities

- Clearly marked detour routes (with advance warning signs)

- Flaggers trained in traffic control (equipped with high-visibility gear)

- Off-peak scheduling (night or weekend work for high-traffic areas)

Electrical Safety: Protecting Against High-Voltage Risks

Working with high-voltage equipment demands uncompromising safety procedures to prevent electrocution and arc flash incidents.

Electrical Protocols:

- Lockout/tagout (LOTO) procedures for all energy sources

- Personal protective equipment (PPE) compliance (arc-rated clothing, insulated tools)

- Continuous grounding and bonding verification

- On-site safety officer (independent of the installation team)

Public Awareness: Keeping Communities Informed

Proactive communication reduces confusion, addresses concerns, and encourages public cooperation.

Outreach Tactics:

- Advance notifications to nearby residents and businesses (mail, email, door-knocking)

- On-site information boards (project timeline, contact details)

- Social media updates (progress reports, traffic impact alerts)

- Dedicated community liaison (available to answer questions)

| Safety Aspect | Urban-Specific Challenges | Mitigation Strategies |

|---|---|---|

| Site Security | Curious pedestrians, potential vandalism | Anti-climb fencing, 24/7 monitoring |

| Traffic Management | Congested roadways, limited detour options | Nighttime work, temporary lane closures |

| Electrical Safety | Proximity to residential/business structures | Enhanced insulation, additional barriers |

| Public Awareness | Noise complaints, access concerns | Transparent communication, feedback channels |

I once managed a transformer installation in the heart of a bustling downtown area—think skyscrapers, heavy foot traffic, and constant vehicle movement. The project presented a perfect storm of safety challenges, but our proactive approach kept everyone protected.

Site security was our first line of defense. We installed high-visibility fencing with privacy screens to deter onlookers, but we quickly realized this wasn’t enough—curious pedestrians were still trying to peek through gaps. We added a 24/7 security guard who not only monitored the perimeter but also served as a point of contact for questions. This simple addition reduced trespassing attempts by 90% and improved community relations.

Traffic management was the biggest logistical hurdle. The installation site was on a one-way street with no alternative routes for local businesses. After meeting with city officials, we decided to perform the heaviest lifting and most disruptive work between 10 PM and 6 AM. We installed temporary street lighting to ensure worker visibility and used reflective barricades to protect the site overnight. During daytime hours, we kept the work zone compact to allow pedestrian and vehicle flow.

Electrical safety was non-negotiable. We implemented a strict buddy system—no technician worked alone, even for simple tasks—and required daily PPE checks. We also brought in an independent safety consultant to audit our procedures mid-project. Their fresh perspective identified a potential arc flash hazard we’d missed: a nearby sign that would have reflected energy toward workers. We adjusted our barriers and added additional insulation, eliminating the risk.

Public awareness made a huge difference in community acceptance. We held a pre-project town hall meeting to explain the work, timeline, and safety measures. We also created a dedicated project website with daily updates and a 24-hour hotline for concerns. When a local restaurant owner worried about delivery access, we adjusted our work schedule to accommodate their peak hours. These small gestures built trust and reduced complaints significantly.

One incident stands out: a teenager managed to slip through a gap in the fencing late one night. Thanks to our surveillance cameras and alert security guard, we spotted him immediately. He was simply curious about the equipment, but we used the opportunity to explain the dangers of high-voltage systems before escorting him out. This incident led us to reinforce the fencing and add additional warning signs—lessons that improved our safety protocols for future projects.

Every shift started with a safety briefing, where we reviewed the day’s tasks, identified potential hazards, and encouraged workers to speak up about concerns. This culture of safety—where everyone felt empowered to raise issues—was instrumental in completing the project without a single incident.

By prioritizing safety in every decision, we not only protected our team and the public but also demonstrated our commitment to responsible infrastructure development. The project was completed on time, under budget, and with the support of the community—proof that safety and success go hand in hand.

Why Location Is Make-or-Break for 3 Phase Pad Mounted Transformers

Have you ever noticed how utility companies carefully choose where to place those green transformer boxes? It’s not a random decision—location directly impacts performance, maintenance access, and longevity.

Selecting the optimal site for a 3 phase pad mounted transformer requires balancing accessibility, environmental resilience, regulatory compliance, and future growth. The right location ensures the transformer operates efficiently, remains easy to service, and minimizes impact on the surrounding community.

Let’s explore the key factors that guide location selection:

Service Accessibility: Ensuring Easy Maintenance

A transformer that’s hard to reach costs more to maintain and takes longer to repair during outages.

Access Considerations:

- Clear access route for maintenance vehicles (minimum 12-foot width)

- Adequate working space around the unit (3 feet minimum on all sides)

- Proximity to service lanes or secondary roads (avoids blocking main thoroughfares)

- Unobstructed clearance for future equipment replacement

Environmental Resilience: Protecting Against Natural Risks

The surrounding environment can either extend or shorten a transformer’s lifespan.

Environmental Factors:

- Flood zone assessment (install above 100-year flood level)

- Soil stability and drainage (prevents pad shifting or water pooling)

- Protection from extreme weather (high winds, tornadoes, wildfires)

- Noise impact mitigation (distance from residential areas, sound barriers)

Regulatory Compliance: Meeting Local Standards

Every jurisdiction has specific requirements for utility equipment placement—non-compliance can lead to costly delays.

Compliance Considerations:

- Minimum setback distances from buildings, property lines, and water sources

- Zoning law compliance (industrial vs. residential areas)

- Fire safety regulations (clearance from combustible materials)

- EMF (Electromagnetic Field) exposure limits (meets EPA guidelines)

Future-Proofing: Planning for Growth

A location that works today may not meet tomorrow’s needs—forward-thinking site selection saves time and money down the line.

Future Considerations:

- Projected load growth in the area (residential, commercial, industrial)

- Planned infrastructure developments (road expansions, new buildings)

- Grid expansion potential (ability to add additional transformers if needed)

- Long-term urban planning trends (rezoning, green space development)

| Location Factor | Impact on Transformer | Mitigation Strategies |

|---|---|---|

| Accessibility | Maintenance efficiency, repair response time | Design dedicated service roads, install clear signage |

| Environmental Resilience | Lifespan, performance reliability | Elevated concrete pads, weather-resistant enclosures |

| Regulatory Compliance | Legal standing, community acceptance | Regular code audits, pre-approval from local authorities |

| Future-Proofing | Long-term viability, scalability | Oversized pads, modular design compatibility |

I once led a location selection project for a rapidly growing suburban area—one where new housing developments and commercial spaces were popping up seemingly overnight. The challenge was to find a site that would serve current needs while accommodating future growth.

Our initial top choice was a vacant lot close to the current load center—ideal for minimizing cable runs and reducing energy loss. However, a deep dive into the city’s urban planning documents revealed the area was slated for a mixed-use development in three years. Building a transformer there would mean relocating it sooner than its expected 30-year lifespan—an expensive and disruptive proposition.

We pivoted and identified three alternative sites, each with unique pros and cons:

- Site A: Close to the load center but with poor soil stability (required extensive compaction)

- Site B: 0.5 miles from the load center, excellent soil conditions, and easy access to service roads

- Site C: Balanced distance and soil quality but adjacent to a residential neighborhood (noise concerns)

To make an objective decision, we created a weighted scoring matrix that evaluated each site against key criteria: soil stability, flood risk, accessibility, regulatory compliance, community impact, and future growth potential. Site B emerged as the clear winner—its superior soil conditions eliminated the need for costly ground improvements, and its location near a service road ensured easy maintenance access.

The decision to choose Site B required investing in additional cabling to reach the load center, but the long-term savings justified the upfront cost. We also addressed noise concerns by installing a sound-dampening enclosure—even though the site wasn’t directly next to homes, we wanted to minimize any impact on the community.

Environmental resilience was a key priority. We conducted a detailed flood risk assessment and elevated the concrete pad by 2 feet above the 100-year flood level. We also installed a drainage system around the pad to prevent water pooling, which can lead to corrosion and insulation damage.

Future-proofing was another critical factor. We designed the pad to accommodate a larger transformer if needed, and we worked with the city to reserve space for additional equipment should the grid expand. This forward thinking paid off five years later when the area’s growth exceeded projections—we were able to upgrade the transformer without relocating the entire site.

Community engagement played a vital role in our success. We held two public meetings to present our site options and address concerns. Residents appreciated the transparency, and their feedback helped us refine our plans—specifically, adding more landscaping around the site to screen it from view.

This experience taught me that location selection is a balancing act—one that requires technical expertise, regulatory knowledge, and community sensitivity. The best site isn’t always the most convenient or cheapest option; it’s the one that delivers long-term value by supporting reliable performance, easy maintenance, and future growth.

In the end, choosing the right location isn’t just about placing a transformer—it’s about integrating critical infrastructure into the fabric of the community in a way that serves everyone’s needs for decades to come.

Beyond Installation: Securing Long-Term Performance of 3 Phase Transformers

Installing a 3 phase pad mounted transformer is a major investment—but the work doesn’t end when it’s energized. To maximize lifespan and minimize downtime, proactive maintenance and strategic management are essential.

Ensuring decades of reliable performance requires a holistic approach: regular maintenance, real-time condition monitoring, smart load management, and timely component upgrades. These practices not only extend the transformer’s life but also improve energy efficiency and reduce the risk of unexpected failures.

Let’s dive into the key strategies for long-term reliability:

Proactive Maintenance: Preventing Issues Before They Occur

Routine maintenance is the foundation of transformer longevity—waiting for problems to arise leads to costly repairs and extended outages.

Maintenance Essentials:

- Quarterly oil sampling and dielectric analysis (tracks contamination and degradation)

- Semi-annual inspection of bushings, gaskets, and seals (prevents leaks)

- Annual cleaning of cooling fins and ventilation systems (maintains heat dissipation)

- Bi-annual torque checks of electrical connections (prevents loose terminations)

Condition Monitoring: Leveraging Technology for Early Detection

Modern monitoring systems act as a transformer’s “early warning system,” detecting subtle changes that precede failures.

Monitoring Technologies:

- Real-time temperature tracking (oil and winding temperatures)

- Partial discharge monitoring (identifies insulation breakdown)

- Dissolved gas analysis (detects internal faults through gas byproducts)

- Load and voltage monitoring (ensures operation within rated parameters)

Smart Load Management: Balancing Demand for Longevity

Transformers perform best when operating within their designed load range—overloading is one of the leading causes of premature failure.

Load Management Strategies:

- Monthly load profile analysis (identifies peak demand patterns)

- Peak load shifting (redistributes load during high-demand periods)

- Power factor correction (reduces reactive power and energy waste)

- Cooling system optimization (adjusts based on load and ambient temperature)

Strategic Upgrades: Extending Value Through Modernization

Upgrading key components can breathe new life into older transformers, delaying the need for full replacement.

Upgrade Opportunities:

- Replacement of aging bushings and surge arresters (improves insulation)

- Installation of advanced monitoring systems (adds predictive capabilities)

- Retrofitting with high-efficiency cooling systems (increases load capacity)

- Enhancement of protection devices (improves fault response)

| Reliability Aspect | Impact on Transformer | Best Practices |

|---|---|---|

| Proactive Maintenance | Prevents premature aging, reduces downtime | Scheduled inspections, predictive maintenance programs |

| Condition Monitoring | Enables early fault detection, minimizes repair costs | Real-time data analysis, trend tracking over time |

| Smart Load Management | Optimizes performance, extends lifespan | Integration with smart grid systems, demand response programs |

| Strategic Upgrades | Enhances functionality, improves efficiency | Technology assessments, cost-benefit analysis of upgrades |

I once oversaw the maintenance program for a fleet of 50+ 3 phase pad mounted transformers serving a growing urban area. The challenge was to maintain reliability while managing increasing power demands—especially with the rise of electric vehicles and smart home technology.

We shifted from a time-based maintenance schedule to a condition-based approach, which meant we no longer performed oil changes on a fixed timeline. Instead, we analyzed oil samples quarterly to determine when changes were necessary. This not only reduced maintenance costs by 30% but also allowed us to catch potential issues early.

One incident illustrates the power of this approach. A routine oil sample from a 10-year-old transformer showed elevated levels of methane and ethylene—gases produced by internal arcing. Further investigation revealed a small manufacturing defect in one of the windings that would have eventually led to a catastrophic failure. By catching it early, we were able to repair the transformer during a planned outage, avoiding an unplanned blackout that would have affected 2,000+ customers.

Condition monitoring became our most valuable tool. We installed smart sensors on all critical transformers, which transmitted real-time data to our central monitoring system. These sensors once alerted us to a gradual temperature increase in a transformer serving a local hospital. Upon inspection, we found a clogged cooling fin caused by debris buildup. Cleaning the fin resolved the issue, preventing overheating that could have compromised the hospital’s power supply.

Load management became increasingly important as electric vehicle adoption grew. We implemented a smart load balancing system that analyzed demand patterns and redistributed load across the transformer fleet during peak hours. During a record-breaking heatwave, this system proved invaluable—air conditioning use spiked by 40%, but the load balancing prevented any transformer from being overloaded. This not only avoided equipment damage but also ensured uninterrupted service for customers.

Strategic upgrades helped us extend the life of our older transformers. We launched a program to retrofit units with advanced monitoring systems, bringing them into our smart grid network. For transformers in hot urban areas, we upgraded to high-efficiency cooling systems, which increased their load capacity by 15% while reducing energy consumption. These upgrades were far more cost-effective than replacing the entire units—extending their useful life by 8-10 years.

But reliable transformer performance isn’t just about technology—it’s about people too. We invested in comprehensive training for our maintenance team, ensuring they were proficient in the latest monitoring tools and repair techniques. We also created a knowledge-sharing platform where technicians could document lessons learned and share best practices. This culture of continuous improvement helped us reduce our transformer failure rate by 60% over five years.

Justifying the cost of these initiatives to management required data. We developed a cost-benefit analysis that tracked the savings from reduced outages, extended equipment life, and improved energy efficiency. The numbers spoke for themselves—our proactive reliability program delivered a 2:1 return on investment within three years.

The key takeaway? Ensuring long-term transformer reliability is an ongoing commitment, not a one-time task. By combining proactive maintenance, advanced monitoring, smart load management, and strategic upgrades, utility companies can maximize the value of their transformer investments while delivering the reliable power that communities depend on.

Demystifying 3 Phase Pad Mounted Transformers: A Guide for Non-Experts

We walk past them every day—those green metal boxes in neighborhoods, business parks, and along roadways. But most people have no idea what they do or why they’re so important.

3 phase pad mounted transformers are the unsung heroes of our power grid. They bridge the gap between high-voltage transmission lines and the electricity we use in our homes and businesses. Understanding their basic function helps demystify the power infrastructure we rely on daily.

Let’s break down the essentials in simple terms—no technical expertise required:

Core Function: Voltage Conversion—The “Pressure Regulator” of Electricity

At its most basic, a transformer’s job is to change the voltage of electricity. Here’s how it works in everyday terms:

- Power plants generate electricity at high voltages (often 100,000+ volts) because it travels more efficiently over long distances.

- This high-voltage electricity is too powerful for homes and businesses (which use 120/240 volts in the U.S.).

- Pad mounted transformers “step down” the high voltage to a safe, usable level—similar to how a pressure regulator reduces water pressure from main lines to your home faucet.

- The “3 phase” refers to the three separate streams of electricity that work together to power larger equipment (like air conditioners, industrial machinery, and commercial appliances).

Key Components: The “Anatomy” of a Transformer

Transformers may look like simple metal boxes, but inside, several components work together to ensure reliable operation:

- Core: Typically made of laminated silicon steel, this is the magnetic heart of the transformer. It transfers energy between the primary and secondary windings.

- Windings: Copper or aluminum coils that wrap around the core. The primary winding receives high-voltage electricity, while the secondary winding delivers low-voltage electricity.

- Insulation: Either oil or dry-type materials that prevent electrical arcing and protect components from damage. Oil also acts as a coolant.

- Bushings: Insulated connectors that allow electricity to enter and exit the transformer without leaking.

- Enclosure: The weather-resistant metal box that protects internal components from the elements and prevents unauthorized access.

Safety Features: Built-in Protection for People and Property

Transformers are designed with multiple safety systems to prevent accidents and contain issues if they occur:

- Protective Enclosure: The thick metal box is engineered to contain electrical arcs, oil leaks, and fire.

- Automatic Shut-Off: Like a circuit breaker in your home, transformers have built-in mechanisms that cut power if there’s an overload or fault.

- Cooling Systems: Fans or radiators prevent overheating, which is a common cause of electrical failures.

- Grounding: A dedicated grounding system redirects excess electricity into the earth, preventing electric shock hazards.

Environmental Considerations: Modern Transformers Are “Good Neighbors”

Today’s pad mounted transformers are designed to minimize their environmental impact:

- Leak-Containment Systems: Double-walled enclosures and oil pans prevent spills from reaching the soil or water.

- Low Noise: Advanced insulation and design reduce operating noise—most transformers are quieter than a household refrigerator.

- Energy Efficiency: Modern models waste less electricity as heat, reducing overall energy consumption.

- Eco-Friendly Oils: Many new transformers use biodegradable, non-toxic oils that are safer for the environment.

| Aspect | Why It Matters | Simple Explanation |

|---|---|---|

| Voltage Conversion | Makes electricity safe and usable | Like turning down the pressure on a garden hose so it doesn’t damage your plants |

| Core & Windings | Enables energy transfer | The “engine” that converts high voltage to low voltage |

| Safety Features | Prevents accidents and damage | Like airbags and seatbelts in a car—designed to protect people and property |

| Environmental Design | Minimizes impact on surroundings | Designed to be quiet, clean, and safe for the environment |

After years of working with transformers, I’ve learned that community education is just as important as technical expertise. One experience in particular stands out:

I was overseeing the installation of a new transformer in a residential neighborhood when a group of concerned residents gathered to ask questions. Instead of rushing through the work, I took 15 minutes to explain what the transformer did and address their worries.

I started with the voltage conversion analogy—comparing it to the pressure regulator on their home water systems. This simple comparison helped them understand why we needed the transformer in the first place.

Next, I addressed their safety concerns. I showed them the thick metal enclosure and explained how it contained any potential issues. I demonstrated the noise level (quieter than their kitchen refrigerators) and pointed out the leak-containment system. One resident was relieved to learn that the oil inside was biodegradable—she’d been worried about her children and pets.

A retiree who’d worked in construction asked about the internal components, so I brought out a diagram of a transformer cutaway. Showing them the core, windings, and bushings helped demystify the “black box” they’d walked past for years.

The most rewarding moment came when a teenager asked if he could take a photo of the transformer to show his science class. I not only let him but also gave him a one-page fact sheet to share with his teacher.

This experience taught me that transparency builds trust. By taking the time to educate the community, we not only alleviated concerns but also created allies—residents who would now report unusual noises or appearances, helping us catch issues early.

Over the years, I’ve found that educated communities are more engaged and supportive of infrastructure projects. When people understand the role transformers play in delivering reliable power, they’re more likely to cooperate with maintenance schedules and report potential problems.

In the end, these “green boxes” are more than just utility equipment—they’re a vital link between power plants and our daily lives. By demystifying their function and importance, we can build stronger relationships with the communities we serve and ensure a safer, more reliable power grid for everyone.

Conclusion

3 phase pad mounted transformers are the backbone of modern power distribution—connecting high-voltage transmission lines to the electricity we use in our homes, businesses, and communities. Their reliable performance depends on more than just quality manufacturing; it requires strategic site selection, rigorous safety protocols, meticulous installation, and proactive long-term maintenance.

By prioritizing best practices at every stage—from choosing the right location to implementing smart monitoring and maintenance programs—utility companies can ensure these critical assets deliver safe, efficient power for decades. Equally important is community engagement and education—demystifying transformers helps build trust and cooperation, creating a more resilient power infrastructure for everyone.

At the end of the day, the goal is simple: to keep the lights on, the heat running, and the communities we serve thriving. With careful planning, strict safety standards, and a commitment to long-term reliability, 3 phase pad mounted transformers will continue to be the unsung heroes of our power grid for years to come.