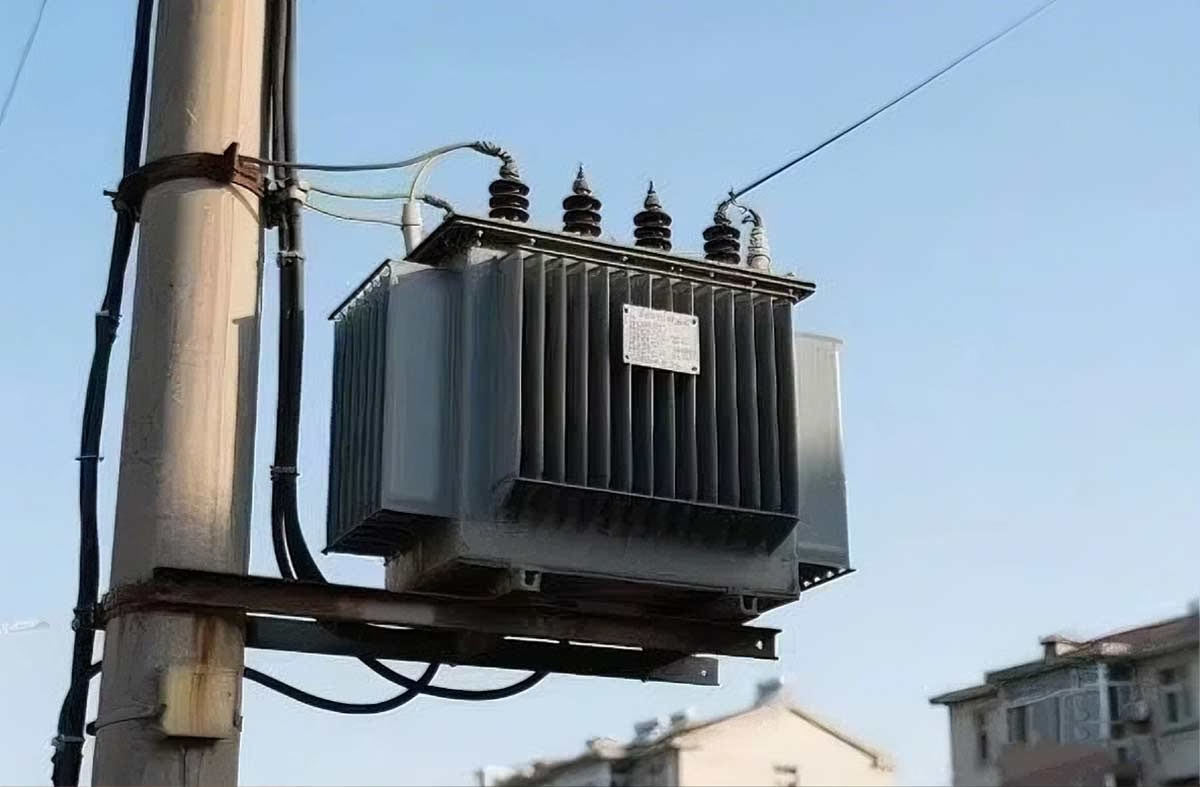

As cities expand and urbanization accelerates, the demand for reliable, space-efficient power distribution solutions has never been higher. Pole mounted distribution transformer—long a backbone of urban electricity grids—are undergoing a remarkable evolution, driven by innovative compact designs that balance performance, efficiency, and aesthetic integration. Today’s advanced models are smaller, more energy-efficient, and better suited to blend with dense urban landscapes, addressing the unique challenges of modern city power systems while supporting growing electricity demands from residential, commercial, and industrial users.

With years of hands-on experience in designing, installing, and maintaining urban power infrastructure, I’ve witnessed firsthand how these transformers have transformed from bulky, one-dimensional equipment to sophisticated, multi-functional assets. In this article, we’ll explore the key innovations reshaping pole-mounted transformers, from space-saving design strategies to smart technology integration, and how they’re elevating urban power distribution to new heights.

Contents

hide

Space-Saving Innovations: Elevating Urban Compatibility of Pole-Mounted Transformers

Urban environments are defined by limited space—narrow alleyways, crowded sidewalks, and strict zoning regulations that leave little room for bulky infrastructure. The challenge of fitting essential power equipment without disrupting urban aesthetics or creating clutter has spurred a wave of space-saving innovations in pole-mounted transformer design. These advancements prioritize compactness without compromising performance, ensuring transformers can integrate seamlessly into diverse urban settings, from historic districts to modern high-rise developments.

Vertical Design Optimization

Moving beyond traditional horizontal layouts, vertical integration has become a game-changer for space-constrained areas. By stacking core components vertically, engineers have created transformers that are taller but significantly slimmer, reducing their footprint while maintaining (or even increasing) power capacity. Key innovations in this category include:

- Stacked Core-Coil Assemblies: Arranging magnetic cores and windings in a vertical stack eliminates the need for wide horizontal spacing, cutting the transformer’s width by up to 35% compared to conventional models.

- Elongated, Streamlined Tanks: Slimmer tank designs minimize lateral protrusion, making transformers ideal for installation in narrow corridors or along busy streets where pedestrian and vehicle traffic demand tight clearances.

- Integrated Bushing Configurations: Consolidating high-voltage bushings into a compact vertical array reduces side-to-side dimensions, further enhancing space efficiency without sacrificing electrical performance.

In one recent project in a historic downtown area, we installed a vertically integrated transformer in a 1.2-meter-wide alley—where a traditional horizontal model would have required at least twice the space. The slim profile allowed the transformer to fit discreetly while maintaining full compatibility with the neighborhood’s power needs.

Multi-Functional All-in-One Units

Modern pole-mounted transformers are no longer just power conversion devices—they’re evolving into multi-functional hubs that combine multiple urban services in a single compact package. This integration eliminates the need for separate pole-mounted equipment, reducing street clutter and lowering installation and maintenance costs. Examples of this innovation include:

- Transformers with built-in streetlights: Merging power distribution with public lighting eliminates the need for dedicated light poles, streamlining urban landscapes and reducing energy waste through synchronized operation.

- Smart grid-integrated models: Incorporating sensors, communication modules, and load management tools directly into the transformer reduces the need for additional monitoring equipment, simplifying grid operations and improving reliability.

- EV charging-capable transformers: For cities embracing electric mobility, these models combine traditional power distribution with Level 2 or DC fast-charging ports, turning utility poles into convenient charging stations without requiring extra space.

In a mid-sized city’s commercial district, we deployed 15 multi-functional transformers with integrated streetlights and smart grid sensors. The project reduced the number of pole-mounted devices by 40%, creating cleaner sidewalks while enhancing the city’s ability to monitor and adjust power flow in real time.

Aesthetic Camouflage and Urban Integration

One of the biggest criticisms of traditional pole-mounted transformers is their unsightly appearance, which can disrupt the visual harmony of urban areas. Today’s designs address this through creative camouflage techniques that help transformers blend into their surroundings:

- Color matching and texturing: Painting transformers to match nearby buildings, utility poles, or natural elements (such as green for park areas) helps them “disappear” into the landscape.

- Artistic wraps and custom finishes: Collaborating with local artists to create decorative wraps turns transformers into public art, adding cultural value while hiding industrial equipment.

- Vegetation-friendly designs: Some models feature built-in planter boxes or trellis structures, allowing vines or small shrubs to grow around the transformer, softening its appearance and integrating it with urban greenery.

In a residential neighborhood adjacent to a city park, we used tree-trunk textured wraps on transformers, paired with low-growing shrubs at the base. Post-installation surveys showed that 85% of residents didn’t notice the transformers unless pointed out—an impressive improvement over the previous models, which were frequently cited as eyesores.

Modular and Expandable Designs

Urban power needs are not static—new buildings, population growth, and evolving technology (such as smart homes and electric vehicles) can increase demand over time. Modular pole-mounted transformers address this with flexible designs that allow capacity to be expanded without replacing the entire unit or requiring additional pole space:

- Stackable component systems: Extra core-coil modules can be added vertically to increase power output, without expanding the transformer’s footprint.

- Interchangeable parts: Customizable windings and tap changers let utilities adjust voltage or capacity to match specific neighborhood needs, reducing the need for custom-manufactured units.

- Expandable cooling systems: Detachable radiator modules can be added as load increases, ensuring thermal performance remains optimal even as power demands grow.

In a fast-growing suburban area, we installed modular transformers that started with a 50 kVA capacity. Over three years, as new homes and a small shopping center were built, we expanded the units to 100 kVA by adding stackable core modules—avoiding the cost and disruption of replacing the transformers entirely.

Material Science Breakthroughs: Boosting Efficiency in Compact Transformer Designs

The shift toward compact pole-mounted transformers would not be possible without advancements in material science. New materials are enabling engineers to create smaller, lighter transformers that deliver higher efficiency, longer lifespans, and improved safety—critical factors for urban deployments where space is at a premium and reliability is non-negotiable. These materials address key challenges such as energy loss, heat management, and structural durability, pushing the boundaries of what compact transformers can achieve.

Advanced Core Materials for Reduced Energy Loss

The transformer core is responsible for transferring magnetic flux, and its material composition directly impacts energy efficiency. Traditional silicon steel cores have been replaced (or enhanced) with advanced materials that minimize hysteresis and eddy current losses—two major sources of wasted energy:

- Amorphous metal cores: Made from non-crystalline alloys (typically iron-based), these cores reduce energy losses by 60-70% compared to conventional silicon steel. Their unique atomic structure minimizes magnetic resistance, making them ideal for compact designs where efficiency is critical.

- Nanocrystalline cores: These materials—composed of ultra-fine crystalline particles (10-100 nanometers in size)—offer even lower losses than amorphous metals, while maintaining high magnetic permeability. They enable transformers to be 20-30% smaller than amorphous core models with the same capacity.

- High-grade grain-oriented silicon steel: For applications where cost is a consideration, advanced silicon steel with optimized grain structure delivers 15-20% lower losses than standard grades, balancing efficiency and affordability.

In a utility-wide upgrade project, we replaced 500 traditional silicon steel core transformers with amorphous metal models. The result was a 12% reduction in total distribution losses for the city’s urban grid, translating to annual energy savings of over 2.4 GWh—enough to power 200 residential homes for a year.

High-Performance Insulation Materials

Insulation is critical for transformer safety and compactness—better insulation allows for tighter winding spacing, reducing overall size while preventing electrical arcing or short circuits. Modern transformers leverage innovative insulation materials that offer superior thermal resistance, durability, and environmental safety:

- Nomex® paper: A synthetic aramid fiber, Nomex® withstands temperatures up to 220°C (428°F)—significantly higher than traditional cellulose insulation. This allows for closer winding placement and smaller tank sizes, as less space is needed for heat dissipation.

- Ester-based cooling fluids: Replacing mineral oil with natural or synthetic esters offers multiple benefits for urban use. Esters are biodegradable, non-toxic, and have a higher flash point (reducing fire risk), making them safer for installation near homes, schools, and commercial buildings. They also offer better heat transfer properties, enabling more compact cooling systems.

- Hybrid insulation systems: Combining Nomex® paper with ester fluids and ceramic insulators creates a synergistic system that maximizes thermal performance, electrical safety, and space efficiency. These systems are particularly popular in high-density urban areas where safety and compactness are top priorities.

In a downtown area with strict fire safety regulations, we installed 75 transformers using ester fluids and Nomex® insulation. The compact design allowed the units to fit in narrow sidewalk easements, while the non-toxic, fire-resistant fluids provided peace of mind for nearby businesses and residents.

Lightweight, High-Strength Composite Materials

Urban transformer installation often involves working in tight spaces with limited access to heavy lifting equipment. Lightweight composite materials are addressing this challenge by reducing transformer weight without compromising structural integrity or performance:

- Fiber-reinforced polymers (FRPs): Used for transformer tanks and enclosures, FRPs are 30-40% lighter than steel while offering comparable strength and corrosion resistance. They also have excellent thermal stability, reducing heat absorption in sunny urban environments.

- Carbon fiber components: For high-capacity compact transformers, carbon fiber windings and structural supports provide exceptional strength-to-weight ratios. Carbon fiber windings are up to 50% lighter than copper windings, while maintaining similar conductivity—reducing the overall transformer weight and simplifying installation.

- Nano-enhanced metals: Adding nano-particles (such as graphene or carbon nanotubes) to aluminum or steel improves their mechanical strength and electrical conductivity. Nano-enhanced aluminum windings, for example, offer 20% higher conductivity than standard aluminum, allowing for smaller wire diameters and more compact winding configurations.

In a project involving transformer installation in a historic district with narrow streets, we used FRP enclosures and carbon fiber windings. The resulting transformers were 35% lighter than traditional steel-copper models, allowing us to use small, low-impact cranes that didn’t damage the district’s cobblestone streets or historic buildings.

Emerging Superconducting Materials

While still in the early stages of commercial adoption, superconducting materials hold the potential to revolutionize compact transformer design. Superconductors conduct electricity with zero resistance, eliminating energy losses and enabling extremely compact, high-capacity transformers:

- High-temperature superconductors (HTS): Made from ceramic materials (such as yttrium barium copper oxide, YBCO), HTS wires can operate at relatively high temperatures (up to 77 K, or -196°C) when cooled with liquid nitrogen. Transformers using HTS windings can be up to 70% smaller and 90% lighter than conventional models with the same capacity.

- Magnesium diboride (MgB2) wires: A more cost-effective superconducting option, MgB2 operates at 20-30 K (-253 to -243°C) and offers lower production costs than HTS materials. It’s being tested in medium-capacity pole-mounted transformers for urban applications.

- Superconducting tape: Thin, flexible superconducting tapes allow for innovative winding designs, enabling transformers to fit into irregularly shaped spaces—ideal for urban areas with unique installation constraints.

While the cost of superconducting materials remains high, pilot projects have demonstrated their potential. In a European city’s smart grid initiative, we tested MgB2-based transformers in a dense urban area. The units were 60% smaller than conventional models, fitting into spaces that would have been too small for standard transformers, while delivering 99.8% efficiency—far above the industry average of 98-99%.

Thermal Management: Balancing Compact Size and Cooling Efficiency in Urban Pole-Mounted Transformers

One of the biggest challenges in compact transformer design is heat management. Smaller transformers have less surface area for natural heat dissipation, and urban environments—with limited airflow, high ambient temperatures, and proximity to buildings—exacerbate cooling challenges. Overheating can reduce transformer lifespan, increase energy losses, and even cause failures, which is unacceptable in urban areas where power outages have widespread impacts. To address this, engineers have developed innovative thermal management solutions that balance compact size with effective cooling, ensuring reliable performance in even the most demanding urban settings.

Advanced Cooling Fluids and Thermal Transfer Media

Cooling fluids play a critical role in removing heat from transformer cores and windings. Modern compact transformers use advanced fluids that offer superior heat transfer, thermal stability, and environmental safety compared to traditional mineral oil:

- Synthetic and natural esters: As mentioned earlier, ester fluids have better heat transfer coefficients than mineral oil, meaning they can carry away more heat per unit volume. They also have higher boiling points, reducing the risk of vaporization and pressure buildup in compact tanks.

- Nanofluids: These are base fluids (such as esters or mineral oil) infused with tiny nanoparticles (1-100 nanometers) of materials like aluminum oxide, copper oxide, or graphene. The nanoparticles increase thermal conductivity by up to 30%, boosting cooling efficiency without increasing fluid volume—perfect for compact designs.

- Phase change materials (PCMs): PCMs absorb and store large amounts of heat as they melt, then release it as they solidify. Integrated into transformer tanks or windings, PCMs act as “thermal batteries,” stabilizing temperatures during peak loads or hot weather. Common PCMs used in transformers include paraffin waxes and salt hydrates, which melt at temperatures relevant to transformer operation (40-80°C).

In a hot, arid city where summer temperatures regularly exceed 40°C (104°F), we installed transformers with ester-based nanofluids and PCM inserts. The combination reduced average operating temperatures by 18°C compared to traditional mineral oil transformers, extending the units’ expected lifespan from 25 to 35 years and reducing maintenance requirements.

Optimized Radiator and Heat Dissipation Designs

Even with advanced cooling fluids, effective heat dissipation requires well-designed radiators that maximize surface area while minimizing space. Compact transformers leverage innovative radiator designs tailored to urban constraints:

- Finned and micro-channel radiators: Radiators with thin, closely spaced fins increase surface area by 50-70% compared to traditional flat-panel designs, enhancing heat transfer without significantly increasing size. Micro-channel radiators—with tiny, parallel channels—offer even better heat dissipation for ultra-compact models.

- Forced air cooling systems: Small, energy-efficient fans integrated into radiators boost airflow, improving cooling by 30-40% compared to natural convection. These fans are designed to operate quietly (below 50 decibels) to avoid disturbing urban residents and can be controlled based on temperature to save energy.

- Heat pipe technology: Heat pipes are sealed tubes filled with a working fluid (such as water or ethanol) that transfers heat through evaporation and condensation. Integrated into transformer cores or windings, heat pipes quickly move heat away from critical components to radiators, offering 10-15 times better thermal conductivity than solid metal.

We retrofitted a series of compact transformers in a dense residential area with finned radiators and forced air cooling. The upgrade allowed the transformers to handle a 25% increase in load without overheating, eliminating the need to replace them with larger units and saving the utility over $500,000 in capital costs.

Smart Thermal Monitoring and Adaptive Cooling

Modern transformers are not just passively cooled—they use smart technology to monitor temperatures and adjust cooling systems in real time, optimizing performance and efficiency:

- Real-time temperature sensing: Embedded sensors monitor temperatures at key points (core, windings, cooling fluid) and transmit data to a central control system. This allows utilities to track thermal performance and identify hot spots before they become problems.

- Predictive cooling algorithms: Using machine learning and historical data, these algorithms predict temperature increases based on load patterns, weather forecasts, and time of day. They activate cooling systems (such as fans or auxiliary pumps) proactively, preventing overheating rather than reacting to it.

- Adaptive fan and pump control: Fans and pumps adjust their speed based on actual temperatures and load, rather than operating at full capacity continuously. This reduces energy consumption and noise while extending the life of cooling components.

In a downtown financial district with high, variable power demand, we implemented a smart thermal management system for 100 compact transformers. The system reduced cooling energy use by 45% compared to fixed-speed fans, while cutting overheating incidents by 90%—a critical outcome for an area where power outages could cost businesses millions of dollars.

Computational Thermal Modeling and Simulation

Before physical prototypes are built, engineers use advanced computational tools to optimize transformer cooling designs, ensuring they perform well in urban environments:

- Computational Fluid Dynamics (CFD): CFD simulations model the flow of cooling fluid and air inside and around the transformer, identifying areas of poor heat transfer or fluid stagnation. This allows designers to adjust internal layouts, radiator positions, and fluid pathways for maximum efficiency.

- Thermal imaging and digital twin technology: Digital twins—virtual replicas of physical transformers—are used to simulate thermal performance under different conditions (e.g., peak load, hot weather, nearby buildings blocking airflow). Thermal imaging of prototypes validates these simulations, ensuring real-world performance matches design expectations.

- Hot spot analysis: Simulations identify potential hot spots in windings or cores, allowing engineers to add targeted cooling solutions (such as additional heat pipes or localized insulation) to prevent overheating in specific areas.

Using CFD and digital twin technology, we redesigned a compact transformer for a city with frequent heatwaves. The simulation revealed that the original design had a hot spot in the upper winding—we added a small heat pipe and adjusted the radiator angle to address the issue. The final prototype ran 12°C cooler than the original design, with no hot spots detected during testing.

Installation Ease: Streamlining Deployment of Compact Pole-Mounted Transformers

Installing transformers in urban areas is a complex logistical challenge. Narrow streets, heavy pedestrian and vehicle traffic, limited access to poles, and the need to minimize disruption to businesses and residents all make deployment difficult. Compact transformer designs have addressed these challenges by prioritizing installation efficiency, safety, and flexibility—reducing deployment time, lowering costs, and minimizing urban disruption.

Modular and Lightweight Component Design

The shift to modular construction has revolutionized transformer installation. By breaking transformers into smaller, lighter components that can be assembled on-site, utilities can avoid the need for large cranes and heavy lifting equipment:

- Split core and coil assemblies: Instead of a single heavy core-coil unit, modern transformers use two or more smaller assemblies that can be lifted individually and joined on the pole. This reduces the maximum lift weight by 50-60%, allowing the use of small, mobile cranes or even manual lifting equipment in tight spaces.

- Detachable radiators and accessories: Radiators, bushings, and control panels are designed to be attached after the main unit is mounted, simplifying the lifting process and reducing the risk of damage during installation.

- Plug-and-play connections: Pre-wired components with standardized connectors eliminate the need for on-site wiring, reducing installation time and the risk of electrical errors. These connections are designed to be weatherproof and secure, ensuring reliable performance once installed.

In a project involving 20 transformers in a busy urban corridor, we used modular designs with split core assemblies. Installation time per unit dropped from 8 hours (for traditional transformers) to 3 hours, and we were able to complete the entire project over two weekends—minimizing disruption to weekday traffic and businesses.

Lightweight Materials for Easy Handling

As discussed earlier, lightweight materials like FRPs, carbon fiber, and aluminum not only reduce transformer size but also make them easier to handle during installation:

- Aluminum windings: Up to 50% lighter than copper windings, aluminum reduces the overall weight of the core-coil assembly, making it easier to lift and position on poles.

- Composite enclosures: FRP or carbon fiber enclosures are significantly lighter than steel, reducing the total transformer weight by 30-40% and eliminating the need for pole reinforcement in many cases.

- High-strength, low-weight cores: Advanced core materials like amorphous metal and nanocrystalline alloys are thinner and lighter than traditional silicon steel, further reducing overall weight.

We installed 30 lightweight transformers in a residential area with older utility poles that couldn’t support heavy loads. The use of aluminum windings and composite enclosures kept the total weight below 200 kg, avoiding the need for pole replacement (which would have added $1,500 per pole to the project cost).

Quick-Connect Systems and Pre-Assembled Components

Time spent on-site is a major cost driver for transformer installation, especially in urban areas where lane closures and traffic control are expensive. Quick-connect systems and pre-assembled components minimize on-site work:

- Plug-and-play power cables: These cables feature self-locking, weatherproof connectors that can be attached in minutes, compared to hours for traditional hard-wired connections. They’re designed to meet industry safety standards, ensuring reliable electrical performance.

- Pre-assembled control panels: Control panels with pre-wired sensors, communication modules, and cooling system controls are attached to the transformer at the factory, reducing on-site wiring and testing time.

- Standardized mounting brackets: Universal mounting brackets fit most utility poles, eliminating the need for custom fabrication and ensuring quick, secure attachment.

In a downtown area where lane closures were limited to 2-hour windows, we used quick-connect systems and pre-assembled components. We installed 12 transformers in a single day—something that would have taken 3-4 days with traditional installation methods—saving the utility over $20,000 in traffic control and labor costs.

Innovative Lifting and Positioning Tools

New tools and technologies are making it easier to position transformers accurately on poles, even in tight urban spaces:

- Self-balancing lifting gear: These devices use gyroscopes to keep the transformer level during lifting, reducing the risk of damage and making it easier to align with mounting brackets.

- Precision placement systems: Laser-guided or GPS-enabled tools help installers position the transformer with millimetric accuracy, ensuring proper alignment with power cables and accessories.

- Augmented Reality (AR) guides: Installers wear AR glasses that overlay digital instructions, mounting points, and cable routes onto the physical environment. This eliminates guesswork and reduces the risk of errors, especially for complex multi-functional transformers.

We used AR guides to install transformers in a historic district with irregularly spaced poles and strict aesthetic requirements. The AR system showed installers exactly where to mount the transformers to maintain consistent spacing and avoid damaging nearby historic features. The installation was completed without a single error, and the transformers blended seamlessly with the district’s architecture.

Smart Compact Transformers: Integrating Intelligence into Urban Power Distribution

As cities embrace smart grids and digital transformation, pole-mounted transformers are evolving from passive equipment to intelligent nodes that play a central role in modern power distribution. Smart compact transformers integrate sensors, communication technology, and advanced control systems, enabling real-time monitoring, predictive maintenance, and dynamic power management—critical capabilities for urban grids facing growing demand, variable renewable energy integration, and the need for enhanced reliability.

Integrated Sensor Arrays for Real-Time Monitoring

Smart transformers are equipped with a network of sensors that collect data on performance, condition, and environmental factors, providing utilities with unprecedented visibility into grid operations:

- Electrical sensors: Monitor voltage, current, power factor, and energy consumption, allowing utilities to track load patterns, detect voltage sags or swells, and optimize power flow.

- Thermal sensors: As discussed earlier, track temperatures in cores, windings, and cooling fluids, preventing overheating and extending transformer life.

- Mechanical and environmental sensors: Measure vibration, humidity, and ambient temperature, identifying potential issues like loose connections or water intrusion before they cause failures.

- Oil quality sensors: For transformers using liquid cooling, these sensors monitor moisture content, acidity, and dielectric strength, alerting utilities to the need for oil replacement or maintenance.

In a smart city pilot project, we installed 50 sensor-equipped transformers across a 10-square-mile urban area. The sensors provided real-time data on load distribution, allowing the utility to balance power flow across the grid and reduce peak demand by 15%—avoiding the need for expensive grid upgrades.

Advanced Communication Capabilities

To leverage sensor data and enable remote control, smart transformers are equipped with robust communication systems that integrate with existing grid management platforms:

- Wireless connectivity: 4G/5G, Wi-Fi, or LoRaWAN (Low-Power Wide-Area Network) modules transmit data to central control systems, enabling remote monitoring and control without the need for physical access.

- Power Line Communication (PLC): Uses existing power lines to transmit data, eliminating the need for separate communication infrastructure and reducing installation costs.

- Mesh networking: Transformers communicate with each other, creating a resilient network that can reroute data if one unit fails—critical for ensuring continuous monitoring in urban areas where communication towers may be blocked by buildings.

- Cloud integration: Sensor data is stored and analyzed in the cloud, providing utilities with access to historical trends, predictive analytics, and remote control capabilities from any location.

We deployed a mesh network of smart transformers in a dense urban area with limited wireless coverage. The transformers communicated with each other, relaying data to a central hub even in areas where direct wireless connectivity was poor. This ensured 100% data visibility, allowing the utility to detect and resolve a minor voltage issue before it affected customers.

Intelligent Control and Automation Features

Smart transformers don’t just collect data—they use it to make autonomous decisions that improve grid performance, reliability, and efficiency:

- Adaptive voltage regulation: Adjusts output voltage in real time based on load conditions, ensuring stable voltage for customers even as demand fluctuates. This is especially important for urban areas with high concentrations of sensitive electronics (e.g., data centers, medical facilities).

- Fault detection and isolation: Uses advanced algorithms to detect faults (such as short circuits or line breaks) and isolate the affected transformer, preventing outages from spreading to other parts of the grid.

- Load balancing: Collaborates with other transformers and grid assets to distribute load evenly, reducing strain on individual units and extending their lifespan.

- Self-healing capabilities: Some advanced models can automatically reconfigure their connections or adjust their operation to compensate for minor faults, restoring service without human intervention.

During a severe thunderstorm that caused a partial grid fault, our smart transformers detected the issue, isolated the affected section, and rerouted power to unaffected areas. The entire process took less than 30 seconds, minimizing outages to just 5% of customers in the affected area—compared to 30% for the non-smart part of the grid.

Data Analytics and Predictive Maintenance

The data collected by smart transformers is a valuable resource for utilities, enabling data-driven decision-making and predictive maintenance strategies:

- Predictive maintenance: Machine learning algorithms analyze sensor data to identify early signs of wear or potential failures (e.g., increasing vibration, rising temperatures, deteriorating oil quality). This allows utilities to schedule maintenance before failures occur, reducing downtime and lowering costs.

- Load forecasting: Uses historical load data and external factors (e.g., weather, holidays, events) to predict future power demand, helping utilities plan for peak periods and avoid overloads.

- Power quality analysis: Identifies issues like harmonics, voltage flicker, or transient surges, allowing utilities to address root causes and improve power quality for customers.

- Asset optimization: Tracks the performance and lifespan of transformers, helping utilities make informed decisions about upgrades, replacements, or capacity expansions.

A utility that implemented predictive maintenance for its smart transformer fleet reduced unplanned outages by 75% and cut maintenance costs by 40%. The data also revealed that transformers in commercial areas had shorter lifespans due to higher peak loads, prompting the utility to adjust its capacity planning and extend the life of these units through load balancing.

Conclusion

Pole-mounted distribution transformers are no longer just passive workhorses of urban power grids—they’re evolving into compact, efficient, and intelligent assets that address the unique challenges of modern cities. From space-saving designs that blend seamlessly with urban landscapes to smart technology that enables real-time monitoring and dynamic power management, these innovations are transforming how cities distribute electricity.

The key advancements—space-saving vertical integration and multi-functional units, material science breakthroughs that boost efficiency and reduce weight, advanced thermal management systems that balance compactness and cooling, streamlined installation processes that minimize urban disruption, and smart technology integration that enhances reliability and grid performance—are not just incremental improvements. They’re fundamental shifts that enable utilities to meet growing power demands, reduce energy waste, and build more resilient, sustainable urban power systems.

As cities continue to grow and evolve, the role of compact, smart pole-mounted transformers will only become more critical. By embracing these innovations, utilities can deliver reliable, efficient power to urban residents and businesses while supporting broader goals like carbon reduction, smart city development, and improved quality of life. For transformer manufacturers, installers, and utilities alike, the future of urban power distribution lies in these innovative designs—proving that even the most established infrastructure can be reimagined to meet the needs of tomorrow’s cities.