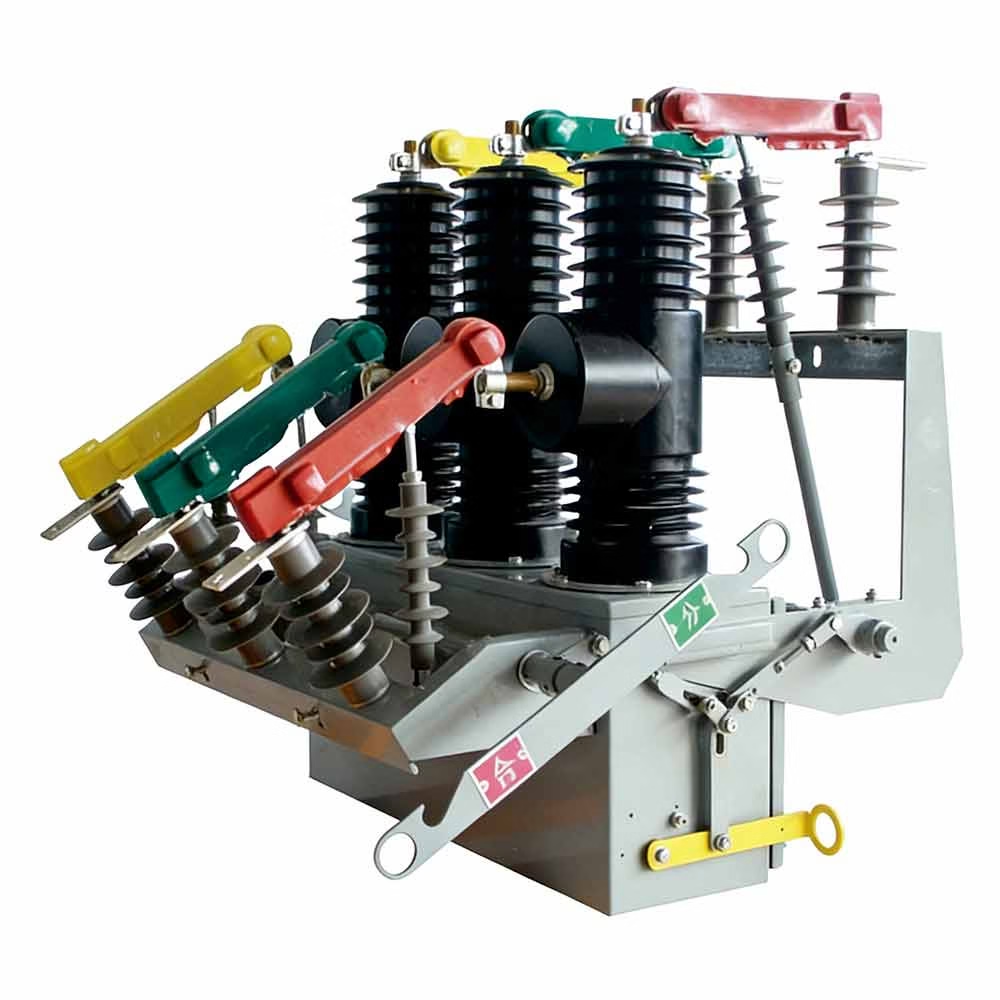

Description

Description of ZN63A(VS1)-12 Series Indoor High-voltage Vacuum Circuit Breaker

The ZN63A(VS1)-12 Series Indoor High-voltage Vacuum Circuit Breaker is a high-performance indoor switching device specifically developed for three-phase AC 50Hz power systems with a rated voltage of 12KV. It serves as a core protection and control unit for power grid equipment and power equipment in industrial and mining enterprises, playing an irreplaceable role in ensuring the safe and stable operation of power systems.

Designed to adapt to harsh working conditions, this series is particularly suitable for occasions requiring frequent operation under rated working current or multiple interruptions of short-circuit current. Its excellent breaking performance and stable operating mechanism enable it to quickly respond to electrical faults, effectively avoiding equipment damage and power outages caused by overloads and short circuits.

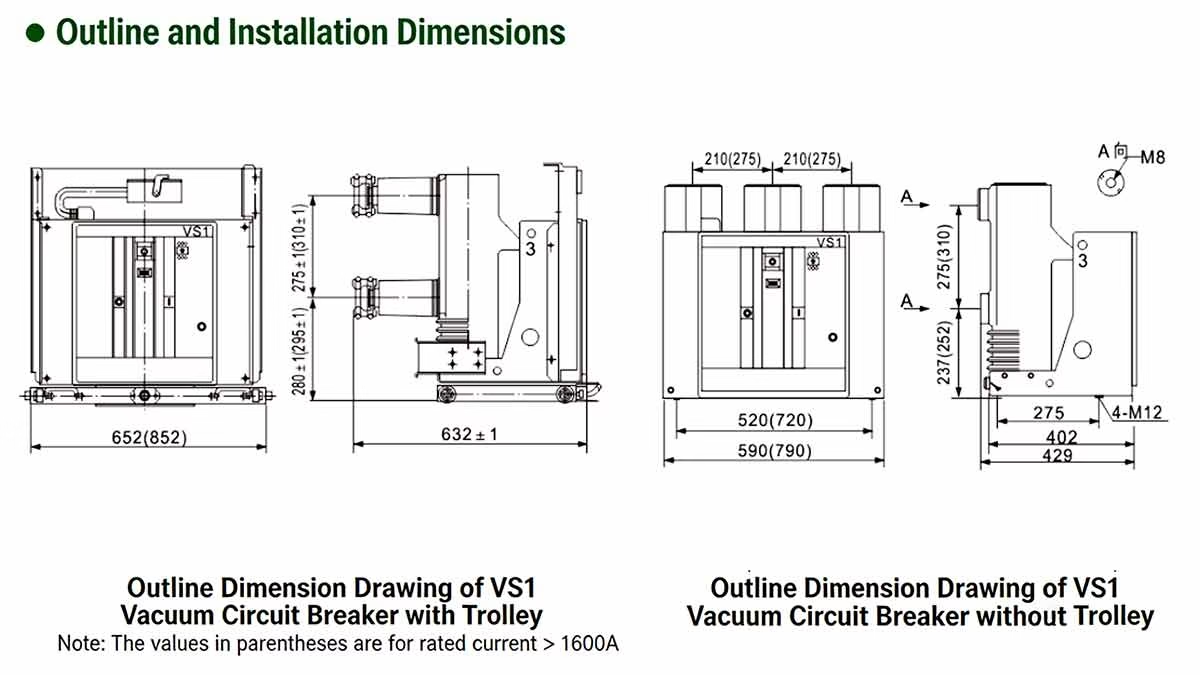

Adopting an integrated design of the operating mechanism and the circuit breaker body, the ZN63A(VS1)-12 Series not only has a compact structure and saves installation space but also features flexible installation methods. It can be used as a fixed installation unit or equipped with a dedicated propulsion mechanism to form a trolley unit, meeting the diverse installation needs of different indoor power distribution scenarios.

Manufactured in strict accordance with national and international technical standards such as GB1984-2014 and IEC60056, the product ensures high reliability, strong compatibility, and excellent performance, fully complying with the strict requirements of modern indoor high-voltage power distribution systems for switching equipment.

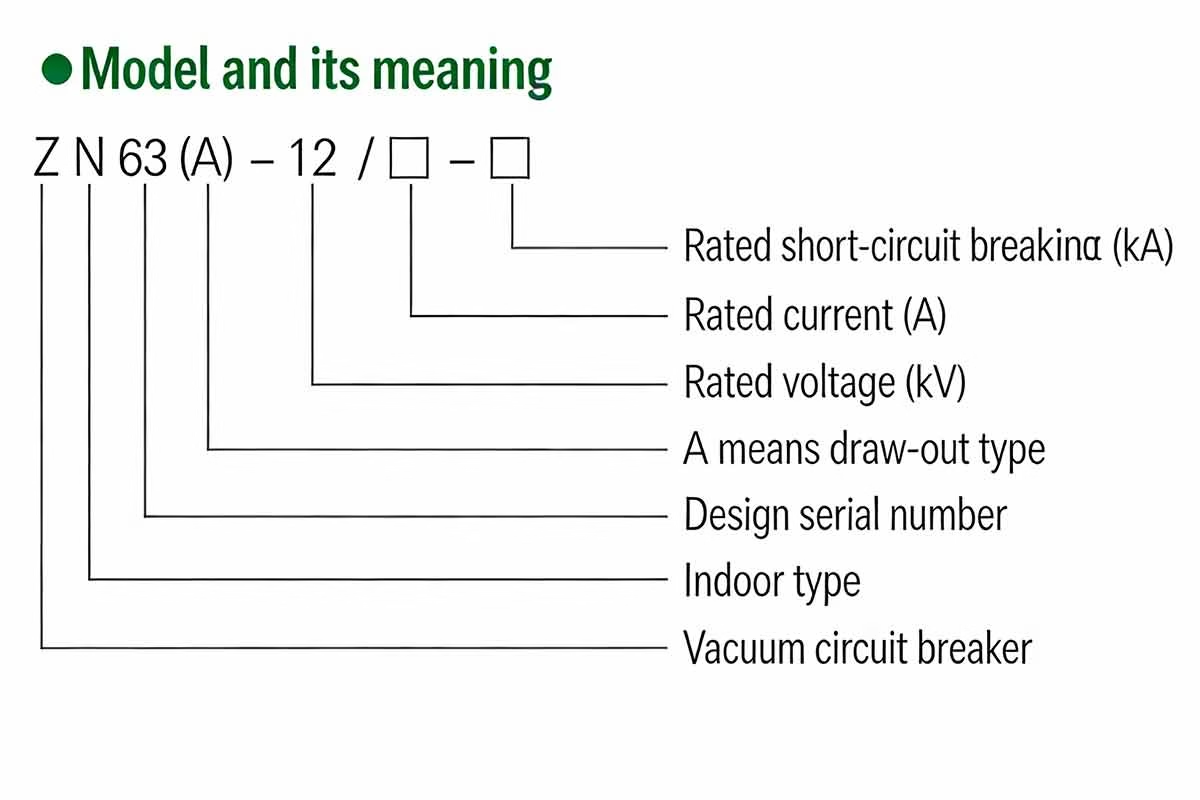

Parameter of ZN63A(VS1)-12 Series Indoor High-voltage Vacuum Circuit Breaker

| number | project | unit | data | ||||

| 1 | rated voltage | kV | 12 | ||||

| 2 | maximum operating voltage | kV | 12 | ||||

| 3 | rated current (A) | A | 6,301,000 | 1250,1600,2000,2500 | 12,501,600 | 20,002,500 | |

| 1250 | 20,003,150 | 3150 | |||||

| 4 | rated short-circuit breaking current | kA | 20/25 | 31.5 | 40 | 50 | |

| 5 | rated short-circuit closing current | kA | 50/63 | 80 | 100 | 125 | |

| 6 | rated peak current rating | kA | 50/63 | 80 | 100 | 125 | |

| 7 | rated short-time current | kA | 20 | 31.5 | 40 | 50 | |

| 8 | rated absolute | power frequency withstand voltage (before and after rated breaking) | kV | 42 (break 48) | |||

| horizontal plane | impact voltage (before and after rated breaking) | kV | 75 (break point 84) | ||||

| 9 | rated operating sequence | Split-0.3 S-merge Split-180 S-merge | |||||

| 10 | mechanical life | Time | 20000 | ||||

| 11 | rated short-circuit breaking current, breaking times | Time | 50 | ||||

| 12 | Rated closing voltage of the actuating mechanism (DC) | V | 110,220 | ||||

| 13 | Rated breaking voltage of the actuating mechanism (DC) | V | 110,220 | ||||

| 14 | clearance between open contacts | mm | 11±1 | ||||

| 15 | overtravel (length of contact spring compression) | mm | 4±0.5 | ||||

| 16 | three-phase separation, asynchronous closing | ms | ≤2 | ||||

| 17 | contact closing bounce time | ms | ≤2 | ||||

| 18 | average breaking speed | S | ≤0.05 | ||||

| 19 | average closing speed | S | ≤0.08 | ||||

| 20 | time of opening | ms | ≤50 | ||||

| 21 | closing time | ms | ≤100 | ||||

| 22 | resistance of the main circuit of each phase | μΩ | ≤40 | ||||

| 23 | accumulation thickness of wear allowance | mm | 3 | ||||

Feature of ZN63A(VS1)-12 Series Indoor High-voltage Vacuum Circuit Breaker

- Integrated Compact Design: The operating mechanism and the circuit breaker body adopt an integrated design, which reduces the overall volume, saves indoor installation space, and simplifies the installation process. At the same time, the integrated structure improves the stability and reliability of the product, reducing the risk of failure caused by loose connections.

- Flexible Installation Methods: It supports two installation modes: fixed installation and trolley-type installation. The trolley unit equipped with a dedicated propulsion mechanism is convenient for maintenance and replacement, allowing on-site personnel to complete equipment inspection and maintenance without the power failure of the entire system, improving work efficiency.

- Excellent Breaking Performance: Adopting advanced vacuum arc-extinguishing technology, it can reliably break rated working current and short-circuit current multiple times. The vacuum interrupter has the advantages of high vacuum degree, low contact wear, and long service life, ensuring stable operation under frequent operation conditions.

- Reliable Protection Function: Equipped with complete overload and short-circuit protection functions, it can quickly detect electrical faults and cut off the faulty circuit in time, effectively protecting power grid equipment, industrial and mining enterprise power equipment from damage, and minimizing economic losses caused by power outages.

- Low Maintenance Cost: The product has a simple structure, and key components such as the operating mechanism and vacuum interrupter are maintenance-free or low-maintenance. It does not require regular replacement of wearing parts, which greatly reduces the later maintenance workload and operational costs for users.

- High Compatibility: Compliant with national and international relevant technical standards, it has strong compatibility with various indoor high-voltage power distribution equipment and automation systems, and can be seamlessly integrated into existing power distribution systems, facilitating system upgrading and transformation.

- Safe and Environmentally Friendly: The vacuum arc-extinguishing method does not produce harmful gases or pollutants, which is in line with modern environmental protection requirements. The shell is made of high-quality insulation materials, which have excellent insulation performance and effectively prevent electric shock accidents.

- Stable Operating Performance: The spring operating mechanism has fast action speed, stable and reliable performance, and can complete switching operations accurately under various working conditions. It is suitable for frequent operation scenarios and ensures the continuity and stability of the power supply.